Milwaukee Ax Carbide Sawzall Blade

Milwaukee Ax Reciprocating Blade

A reciprocating saw, used in construction and demolition work, achieves its cutting action through a push-and-pull (“reciprocating”) motion of the blade. This type of saw, is also known as a recip saw, or Sawzall.

65 years ago Milwaukee invented the reciprocating saw, and since then, SAWZALL is a name that has been synonymous with reciprocating saws. The name says it all, actually. “Sawz-All”

A tool and a blade meant to cut everything!

According to my friend Scott, a tool like a reciproacting saw, is just an expensive “accessory-holder.” Seriously though, there is truth in that a power tool is only as good as the accessory you’re using!

Reciprocating Saw Blades

That brings me to the topic of Sawzall Blades. A recip-saw blade may not have to work that hard in new construction, but on a remodeling site it undergoes a real-life torture test, cutting roofing, nail-embedded wood, pipes, stucco, plaster, fiberglass, drywall and anything else that needs to be removed or cut.

It’s relied on to be aggressive and fast cutting. We all know that when it comes to extreme cutting applications and versatility in a wide range of materials, carbide blades last longer.

Milwaukee Ax Carbide Recip Blade

Reciprocating leadership, in my opinion, is defined by the performance in the recip saw blade. Milwaukee’s new Ax blade is “leading the pack,” with its cutting edge technology.

Pun intended!

Milwaukee engineered a completely different process, material and technology to deliver a blade that could meet the very demanding requirements of the Sawzall.

The Ax Carbide Teeth Sawzall blades are engineered to be the longest-lasting, fastest cutting carbide-tipped recip saw blades on the market.

Milwaukee claims:

- 30X longer life over bi-metal blades

- 2X faster cutting than other carbide blades

Milwaukee Nail Guard

The Blades feature a Nail Guard™ tooth design to prevent nails from fracturing the blade’s teeth upon impact and an aggressive 5 TPI design to deliver fast cuts. Blades with a low TPI deliver faster cuts with rougher edges and are ideal for cutting wood.

Milwaukee Fang Tip

This Fang Tip™ design bites into the wood on first contact to make the cut. A pair of unique, fang-like teeth and an extra-large gullet deliver a fast plunge cut.

The combination of these features allows you to cut through a wide range of materials without sacrificing the life of the blade and with less blade changes.

It comes down to this …

Other wood-cutting carbide blades have had to sacrifice speed for durability, or durability for speed. Milwaukee has found a way to deliver both of these without having to make that compromise.

Testing The Milwaukee AX Blade

I wanted to be able to show you the long-lasting, fast cutting capabilities of this blade.

At the same time I wanted challenge the blade with a realistic test that would challenge every blade, not torture it.

I chose not to use stainless steel, hardened fasteners, or cement board, because those materials are not often cut during remodeling and demolition work.

Nail-embedded wood is key here, and what we cut the most of. I constructed two realistic test boards:

- Simulated Wall Cutting:

I sandwiched two 2x6s on edge, glued up with a layer of plywood in between and capped with outer layer each of drywall and plywood. This was to simulate a residential wall / window header construction.

This test board contained rows of nails, laid end-to-end in saw kerfs cut into the 2x6s: I embedded 16d commons, 10 D commons, and 8d common nails. By locating the nails along both sides of the center piece plywood, I was able to concentrate wear on a limited number of blade teeth. In order to simulate a residential wall detail I added a layer of 1/2-inch CDX plywood and 1/2-inch drywall.

- 2×6 #1 had 4 rows of 16 D nails and 4 rows of 8 D nails

- 2×6 #2 had 4 rows of 16D nails, 2 rows of 8 D nails and 2 rows of 10 D nails.

p.s. – next time someone remind me that drywall makes dust. My shop was a mess!

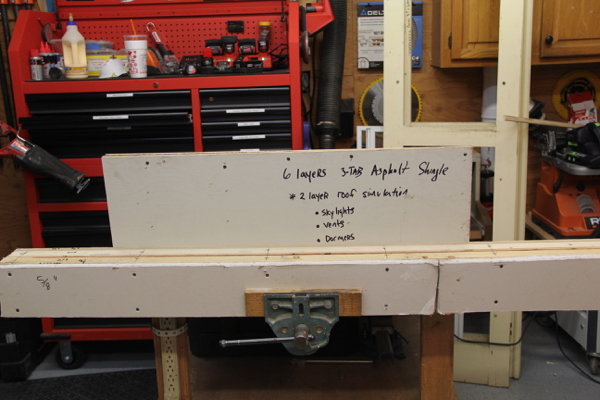

- Simulated Roof Cutting

Since cutting openings for skylights and vents is a common remodeling task, I designed a test to mimic that operation on a three-layer roof. The test consists of six asphalt shingles between two 6-inch rips of ½”-inch MDO plywood. The second layer of MDO was to hold the shingles in place.

Milwaukee AX Saw Blade Test Results

The Results Speak For Themselves. First of all, I was impressed by the longevity, toughness and variety of material that this blade can cut. If I could only buy one blade, this baby is one that could cover most of my needs.

I will note, that there was a point where I terminated the test. The blade continued to cut, and cut, but it was obvious to me that it was dulling and slowing down. If you follow my site ConcordCarpenter, you know I’m big on efficiency. I terminated the tests where I did, because this was the point where I would have changed the blade out.

There are a METRIC TON of guys out there that would continue to cut with this blade … and cut it WILL DO! Just much, much slower.

So How Did I Do With Just ONE Ax Blade?

On the simulated header / wall we made 45 cuts before the blade started slowing down. I also noticed 2 teeth broken.

The results were:

- 90 2×6 cut

- 45 plywood cut

- 45 drywall cut

- 360 – 16d nails cut

- 90 – 10d nails cut

- 270 – 8d nails cut

- 30 cuts through 6 layers of 3-tab shingles

- 30 – 3/8″ rebar cuts

On the Simulated roof cutting we made 30 cuts and the blade continued to cut effortlessly, with no sign of slowing down. So we moved onto something a bit harder to cut. We pulled out some scrap 3/8” rebar proceeded to made 30 cuts. At this point due to my arms and shoulder aching, I terminated the test – the blade was significantly slower but still cutting.

Inspection of the blade at this point indicated 2 to 3 additional broken teeth. If I were in the field I’d have replaced the blade by now – but remember, some guys don’t!

Milwaukee AX Saw Blade – Overall Impression

Let’s Cut To The Chase, these reciprocating saw blades provide fast, aggressive cutting on a variety of materials!

Milwaukee claims that this blade can make more than 1500 cuts in nail-embedded wood, and I absolutely believe it, after putting it through my wall/header/nail cutting rig.

Not only that… they also claim that this blade, which is designed for wood-cutting, is also capable of cutting through a wide range of other materials if needed, like rebar, hardened fasteners and steel. I believe that as well, since I made 30 cuts in rebar with a dull blade.

I really like that Milwaukee continues to develop innovative ideas and designs with unparalleled performance reliability – it certainly makes a huge difference in what I do.

What Could This Mean?

The bottom line is these carbide teeth Ax blades will allow you to be more productive, work faster and smarter with cutting applications.

Sometimes it’s the small details that make a big difference, and this means that your sawzall will be better equipped to … SAW-ALL!

Time to clean the shop!!

Milwaukee Ax Carbide Sawzall Blade Video Review

About the author

1 Comment

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Thanks for This Test an Info. I’ve Destroyed a LOT of Other Blades cutting through Oak and Nails. Def. have to Try These.