24 Tooth Framing Blade Test

7-1/4 Inch Framing Saw Blade Testing | 2022

Saw blades come in a variety of designs, primarily revolving around the number of teeth. Blades with more teeth yield a smoother cut, and blades with fewer teeth remove material faster. Standard 7 and one-quarter framing blades have 24 teeth and are effective for cutting jobs such as rough carpentry, where speed is prioritized over an ultra-smooth cut.

Saw Blade Test Specifications

We wanted to test a 10-dollar framing blade commonly used to cut pressure-treated wood, 2x lumber, plywood, hardwoods, and softwoods, and see how they held up under extreme cutting conditions. The decision was easy for us since we had just finished our Best 7-1/4” Circular saw Head-to-Head test and still had our saw testing rig set up.

Saw Blades Tested

We chose to test 7 common 24-tooth framing blades in the range of 10 to 12 dollars. The blades were:

Crescent Nail Slicer 24-tooth 7-1/4” Framing blade

• Cost $10.00

• Carbide Teeth

• Protective Blade Coating

• Anti-Nail Kickback Tooth Design

• Active Shield™ Protective Blade Coating

• Laser Cut Vibration Slots

• Laser Cut Expansion Slots

• Available at Lowe’s

Dewalt Framing 24-tooth 7-1/4” Framing blade

• Cost $10.00

• Body Slots reduce vibration

• thin kerf design

• High-Density Tungsten Carbide teeth

• ToughCoat anti-stick coating

• Patented body slots reduce vibration

• High-density tungsten carbide

• Reinforced shoulder for impact resistance in nail-embedded wood

Diablo 24-tooth 7-1/4” Framing blade

• Cost $10.00

• Carbide tipped

• Point tooth design

• Anti-vibration design.

• TiCo high-density carbide

• Perma-shield non-stick coating

• Framing blade

Makita Ultra-Thin Kerf 24-tooth 7-1/4” Framing blade

• Cost $11.00

• Tungsten Carbide-Tipped

• ATAFR (Alternate Top Alternate Face with Raker)

• Ultra-Thin 0.057 in. kerf

• Top bevel angle designed with a sharp 23 tip

• Reduced swing width allow for smoother material removal with less cutting resistance

• Slimmer tip bottoms provide lower cutting resistance

• Blade coating provides reduced pitch build-up

• Framing blade

Milwaukee 24-tooth 7-1/4” Framing blade

• Cost $12.00

• Tungsten carbide teeth

• Precision ground teeth

• Expansion slots

• Cooling vents

• Anti-kickback shoulder

• Thin kerf design

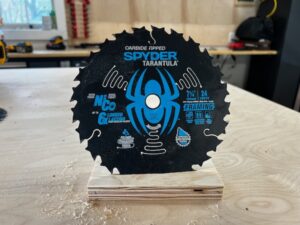

Spyder Tarantula 24-tooth 7-1/4” Framing blade

• Cost $10.00

• Ultra tough NiCo (nickel cobalt) cutting teeth make the cleanest cuts

• Anti-friction coating and stabilization vents

• Nickel cobalt (NiCo) teeth

• Alternating tooth bevel (ATB)

• Anti-friction coating

• Polymer filled stabilization vents reduce noise and vibrations

Blade Performance Testing

The speed at which a circular saw can cut through a particular material is a factor of the blade shape (width, diameter, tooth count, and tooth shape), blade rotational speed, and horizontal force applied.

We wanted to accelerate the wear and tear stress on these blades so we designed a brutal 8-foot nail-embedded wood rip-cut.

Three separate cuts were performed and the time was averaged. We used three new 6.0 Ah Flexvolt batteries, and three new blades for the three cut test.

For cutting material, we used an 8-foot long 2×10 KD with 16 penny nails embedded every 1 inch. The material was marked every inch, into the side of the board, pre-drilled along the center axis to reduce splitting. We then drive 3-1/2 inch, 16D nails in with a hammer resulting in a total of 94 nails.

Circular Saw Variables

For our test saw, we chose to use the winner of our Head-to-Head test, the Dewalt FlexVolt model # DCS5781 circular saw.

We made 3 cuts for an average time. Cycling through 3 new 6Ah Flexvolt batteries and using 3 new saw blades. For every test, we used a fully charged, ambient temperature battery in the Dewalt saw. After each test, the saw was allowed to rest for 5 minutes and also cooled with compressed air through the vent slots. We did not experience any electronic or battery overload issues during this testing.

Controlling Cutting Variables

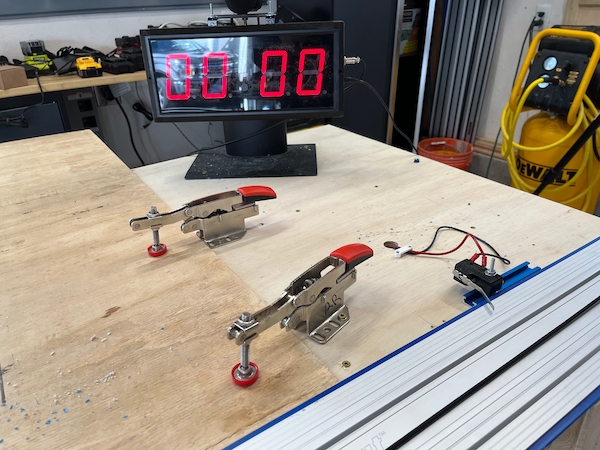

To test the longevity and cutting power of these saw blades the TBB crew needed to control cutting variables. We achieved this by using the same circular saw and same board and nails for each cut. A drop-weight pulley system and low friction saw sled rig was used to achieve a repeatable constant force cut.

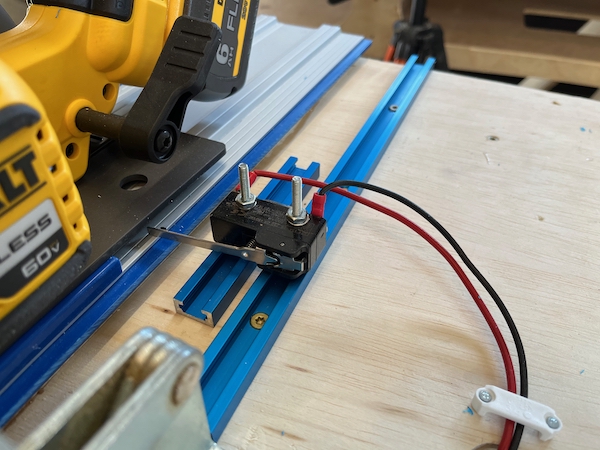

For our cutting sled, we used a Kreg Accu-cut track system, secured to our testing rig, and an 8-foot section of 2×10 KD lumber was indexed underneath. The Accu-cut sled was pulled by a line, and a series of low friction pullies and attached to an 11 lb. weight which provided a consistent 11lb horizontal force to pull the saw through the cut.

After each cut, the sled and track were cleaned of all sawdust and debris. Before the first run of each saw the sled was lubricated with silicone spray and inspected to ensure a smooth low friction cut.

Controlling Timing Variables

Electro-mechanical micro-switches were secured to the start and stop sections of the cutting rig. The time automatically started as the saw began its cut and again automatically stopped as the sled reached the far end, and the cut was finished.

If a blade was unable to complete the full cut before the blade deteriorated to a point where smoking or safety became a concern the timer was manually stopped, and the length of cut was noted.

Nails Cut Results – Winner Diablo

We used “nails cut” vs. “time cut” as a scoring variable. As a remodeling contractor, I’d much rather have a blade last longer than cut faster and wear out sooner.

The winner of the test was the Diablo Framing blade which cut 94 nails in 34-seconds. It was also the only saw to complete the full rip cut and clearly had more life in the blade to cut additional material.

| Blade | Nails/Inches Cut | Time | Rank |

| Diablo Framing | 94 | 34 | 1 |

| Crescent Nail Slicer | 91 | 54 | 2 |

| DeWalt Framing | 87 | 67 | 3 |

| Milwaukee Framing | 87 | 80 | 4 |

| Spyder Tarantula Framing | 86 | 32 | 5 |

| Irwin Marathon | 64 | 38 | 6 |

| Makita Framing | 41 | 21 | 7 |

Second place went to the Crescent Nail Slicer cutting a total of 91 nails in 54 seconds before the blade was unable to continue cutting.

Third place was a tie between the Dewalt [87 nails in 67 seconds] and Milwaukee framing blades [87 nails in 80 seconds] The Spyder Tarantula blade came one nail short at 86 nails in 32 seconds. It cut almost as fast as the Diablo blade but the cutting capacity diminished and the saw stopped cutting.

Note – Many of these saw blades stopped on the track but could be manually pushed thru additional nails [with more pushing force] but we did not record that.

Conclusion

This test had some impressive results and proved to us that a 10-12 dollar blade can be successful and productive in a framing and remodeling environment when cutting nail-embedded wood.

24 Tooth Framing Blade Test | Video Review

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.