Best Portable Jobsite Table Saw – Head-To-Head

Best Portable Jobsite Table Saw

One of the most widely used power tools for carpenters is the table saw. For carpenters that don’t work exclusively in the shop a portable jobsite table saw is essential. For this Head-to-Head we’re focusing on corded portable 10″ jobsite table saws. We are not including cordless table saws in this test as we plan on doing another head-to-head exclusively for cordless table saws later this year as several are available now.

Portable Table Saw Lineup

This portable jobsite table saw head-to-head includes 8 saws from; Bosch, Delta, DEWALT, Hitachi, Makita, Ridgid, SawStop and Skilsaw. Originally, we had also to include Ryobi as a budget friendly option for DIY’ers or guys just starting in the trades. However, we were not able to adapt that saw to our testing rigs so we pulled it from the testing (you may see some photos with the saw but again we’re not including it in the results).

- Bosch Model 4100-09 10 In. Worksite Table Saw with Gravity-Rise™ Wheeled Stand

- Delta Model 36-6022 Portable Table Saw with Stand

- DEWALT Model DWE7491RS 10″ Jobsite Table Saw 32 – 1/2″ Rip Capacity, and a Rolling Stand

- Hitachi Model C10RJ 10″ Jobsite Table Saw w Fold Roll Stand

- Makita Model 2705X1 10” Contractor Table Saw with Portable Stand

- Ridgid Model R4513 Heavy Duty 10 in. Portable Table Saw With Stand

- SawStop Model JSS-MCA Jobsite Table Saw

- Skilsaw Model SPT99-12 10″ Heavy Duty Worm Drive Table Saw

Table Saw Evaluation Format

Once again our team has put some serious time and effort into our Head-to-Head evaluation to bring you the most comprehensive information available. For this evaluation, we broke things into several categories including: Precision & Accuracy, Performance (power), Price, and Ergonomics. For each of these categories we’ll rank the saws and at the end we’ll name the Best Portable Jobsite Table Saw based on all the results combined.

- Precision & Accuracy – In this category we evaluated the accuracy of the table saws straight out of the box, and how easy it is to make calibration adjustments. We also discuss the quality of the fence system as it relates to ripping accurate cuts.

- Performance – The performance evaluation took a very deep dive into the power of the saw motors and how well the saws managed different ripping materials including plywood, pressure treated Southern Yellow Pine 5/4 decking and Mahogany 5/4 decking. We measured saw RPM’s and Amps for each of the cutting materials under constant feed rates.

- Price – Price is always an important factor in determining which saw is best for a user. We’ve included the current pricing found online for each of the saws at the time of publication.

- Ergonomics – Ergonomics are really important to users and an important category to consider when purchasing any power tool. In addition to traditional ergonomics, we also included functionality in this category.

Portable Jobsite Table Saw Features

Before we present the testing results, it’s helpful to set the stage by listing all the features and specifications for comparison. All 8 of these jobsite table saws are similar in size and capacity. Each of the saws uses a 10 inch blade, 15 amp motor and they are all able to use a dado set. Specific differences in the saws are listed below.

- Bosch 4100-09

- Weight: 112 lbs (w/ stand)

- MAX no Load Speed: 3,650 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cut at 45 Deg.: 2-1/2″

- MAX Rip Cut to Right of Blade: 25″

- MAX Dado Cut Width: 13/16″

- Traditional sliding fence.

- Delta 36-6022

- Weight: 92 lbs (w/ stand)

- MAX no Load Speed: 5,000 rpm

- Dept of Cut at 90 Deg.: 3-1/2″

- Depth of Cut at 45 Deg.: 2-1/2″

- MAX Rip Cut to Right of Blade: 30″

- MAX Dado Cut Width: 13/16″

- Traditional sliding fence

- DEWALT DWE7491RS

- Weight: 90 lbs (w/ stand)

- MAX no Load Speed: 4,800 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cut at 45 Deg.: 2-1/4″

- MAX Rip Cut to Right of Blade: 32-1/2″

- MAX Dado Cut Width: 13/16″

- Rack and pinion fence

- Hitachi C10RJ

- Weight: 96 lbs (w/ stand)

- MAX no Load Speed: 4,500 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cut at 45 Deg.: 2-1/4″

- MAX Rip Cut to Right of Blade: 35″

- MAX Dado Cut Width: 13/16″

- Rack and pinion fence

- Makita 2705X1

- Weight: 114 lbs (w/ stand)

- MAX no Load Speed: 4,800 rpm

- Dept of Cut at 90 Deg.: 3-5/8″

- Depth of Cut at 45 Deg.: 2-1/2″

- MAX Rip Cut to Right of Blade: 25″

- MAX Dado Cut Width: 13/16″

- Traditional sliding fence

- Ridgid R4513

- Weight: 80 lbs (w/ stand)

- MAX no Load Speed: 5,000 rpm

- Dept of Cut at 90 Deg.: 3-1/2″

- Depth of Cut at 45 Deg.: 2-1/2″

- MAX Rip Cut to Right of Blade: 25″

- MAX Dado Cut Width: 3/4″

- Traditional sliding fence

- SawStop JSS-MCA

- Weight: 108 lbs (w/ stand)

- MAX no Load Speed: 4,000 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cut at 45 Deg.: 2-1/8″

- MAX Rip Cut to Right of Blade: 25-1/2″

- MAX Dado Cut Width: 13/16″

- Traditional sliding fence

- Safety: Flesh Sensing Technology exclusive to SawStop

- SkilSaw SPT99-12

- Weight: 98 lbs (w/ stand)

- MAX no Load Speed: 5,000 rpm

- Dept of Cut at 90 Deg.: 3-5/8″

- Depth of Cut at 45 Deg.: 2-3/10″

- MAX Rip Cut to Right of Blade: 30-1/2″

- MAX Dado Cut Width: “13/16″, but presently comes with an insert that only allows 1/2

- Rack and pinion fence

One of the things we looked at was the ease of assembly out of the box. We had the same person assemble each of the saws and timed the assembly to see if there are any significant differences between the models. The assembly time for the saws ranged from 21 minutes to 48 minutes. While some stands required more than twice the time, we felt the assembly time was not a significant enough factor to change someone’s mind on which saw to purchase.

We also did some testing of dust collection to see if there were any significant differences between the saws. We attached a Bosch dust extractor to each saw and measured the weight of dust collected for a fixed number of cuts. The bottom line is with a good dust extractor attached there was negligible difference between the saws.

Lastly, we spent some time evaluating the fences. Overwhelmingly the crew really likes the rack and pinion fences that DEWALT, Hitachi and SkilSaw have on their saws. Rack and pinion fences are quicker to adjust, hold in place better during cuts, and provide better accuracy.

Portable Jobsite Table Saw Precision & Accuracy

In the commercial construction business, we typically buy a job site saw for each project and use it up during the course of an 18-month job. When these saws hit the site, they are unboxed, assembled and immediately put into use. We rip stacks and stacks of sheet goods with these saws and the tolerances of the cut materials are not very critical. However, that example represents the portable saw use within our commercial crews’ business.

What if a contractor uses their job site saw for high quality built-ins or high tolerance finished cuts? In that case, saw accuracy is critical for that work. In this use case, if the saw is immediately put into use, success depends upon the out-of-the-box accuracy from the manufacturer. The quality of the cuts and more importantly the potential safety of the operator is going to be a function of the as-shipped accuracy of the saw from the manufacturer.

TBB compared the relative accuracy of the test saws as soon as we assembled and set them up. How would the saws in the TBB Head To Head test compare to each other? We measured the manufactured tolerances and found out. We analyzed the data from the tests and ranked these saws for as-built accuracy.

What and How We Measured

To assess the manufactured accuracy of the eight saws, TBB looked at six areas to measure and compare: Table Flatness, Accuracy of 45 Deg. Stop, Accuracy of 90 Deg. Stop, Blade Parallel to Miter Slot, Fence Parallel to Miter Slot, and Blade Runout.

Table Flatness

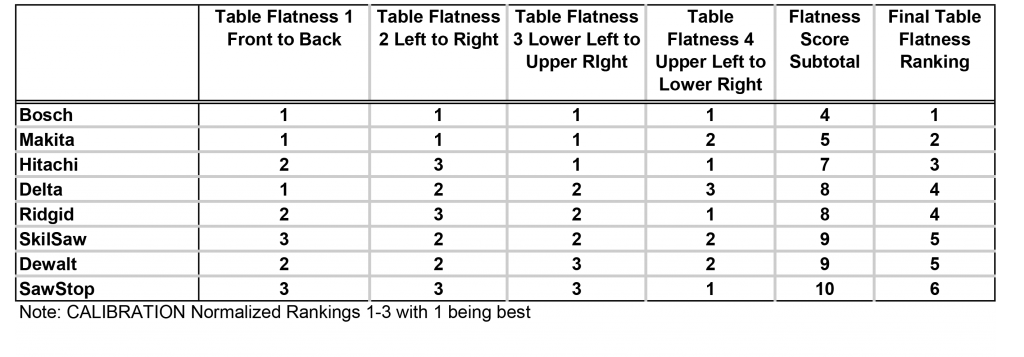

We evaluated the flatness of the table by measuring the flatness by placing the edge of a precision ground flat bar across the table and placed feeler gauges in any gaps to measure any difference between the ground bar and the table. TBB took measurements in four directions. As the operator faces the saw, we measured the flatness at the arbor from front-to-rear; we measured the left-to right flatness at the arbor; we measured the flatness from the upper left-to-lower right table corners; and, finally, we measured the upper right-to-lower left flatness between the corners.

We compiled this set of data and created a ranked set of results by assigning a 1-2-3 rating to the relative values of the test measurements. Then we ranked the saws for overall as-manufactured table flatness. As a point of interest, a typical sheet of copy paper is approximately .004 inches thick. Flatness measurements varied from 0.0 to .09 inches.

All of the data for the table saw flatness can be found here. The overall ranking of the table saw flatness is in the following table:

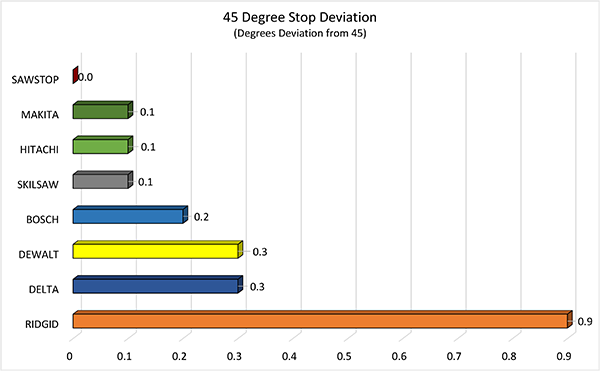

Accuracy of 45 Deg. Stop

Accuracy of 45 Deg. Stop

TBB measured the accuracy of the factory-set 45 degree stop by using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the table and calibrated the inclinometer to the table by zeroing out the gauge. After that calibration, the measurements shown on the gauge give a result that is relative to the saw table. We attached the gauge to the blade and used the saw mechanism to adjust the blade incline to the point at which the blade or trunnion hit the factory-set 45 degree stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every case, the result came out to within 0.1 degree of the prior test.

As you can see below most of the saws were fairly close to 45 degrees right out of the box, but you’ll want to do some calibration if you plan on doing some finish work. SawStop was perfect out of the box and Makita, Hitachi and SkilSaw were very close with only a 0.1 degree deviation. Ridgid was almost a full degree off from the 45 stop.

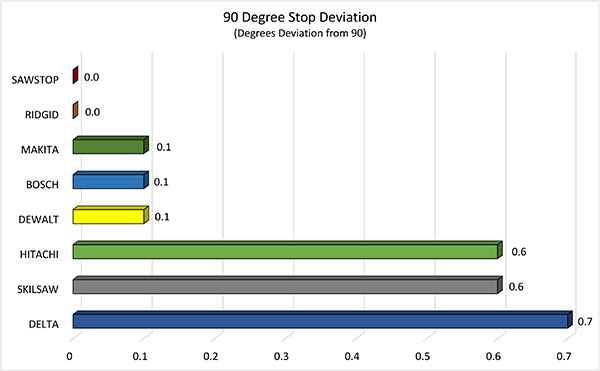

Accuracy of Vertical 90 Deg. Stop

TBB measured the accuracy of the factory-set 90 degree stop by using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the table and calibrated the inclinometer to the table by zeroing out the gauge. After that calibration, the measurements give a result that is relative to the saw table. We moved the blade to an approximate position of 70 degrees off vertical. TBB attached the gauge to the blade and used the saw mechanism to adjust the blade incline to the point at which the blade or trunnion hit the factory-set 90 degree vertical stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every case, the result came out to within 0.1 degree of the prior test.

The results are shown below for the accuracy of the 90 degree stop. For this evaluation both the SawStop and Ridgid were perfect at 90 degrees, Makita, Bosch and DEWALT were also only off by a small amount at 0.1 degrees. The Hitachi, Delta and SkilSaw could use some calibration.

Blade Parallel to Miter Slot

TBB used an iGauging 35-125-4 digital dial indicator to measure the accuracy of the blade position to the table miter slot. This instrument has an accuracy of .0005 inches. As part of the table saw set-up, TBB installed a new Diablo blade in each saw and these never-before-used blades were used in the measurement test. To ensure that any wobble in the blade did not enter into the test results, TBB marked a single tooth as the reference point for the measurement. The blade position was moved to the front of the saw to allow the iGauging dial indicator to hit the tooth immediately behind the carbide tooth, The iGauging dial indicator was calibrated and the indicator had a reading of zero.

We rotated the blade to the rear of the saw to enable the dial indicator to contact the same location of the same tooth behind the carbide portion. We positioned the dial indicator to the rear of the saw placed onto the blade and the reading recorded. If the blade and the miter slot were closer together at the rear of the saw, the dial indicator has a negative reading. If the blade and the miter slot were father apart at the rear of the saw, the dial indicator showed a positive reading.

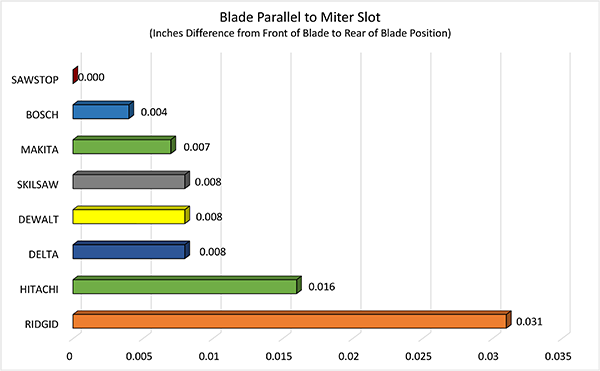

The results for the blade parallel to the miter slot are shown below. Again the SawStop had a perfect reading right out of the box and the Ridgid needs some extra calibration in order to get the blade more parallel to the miter slot.

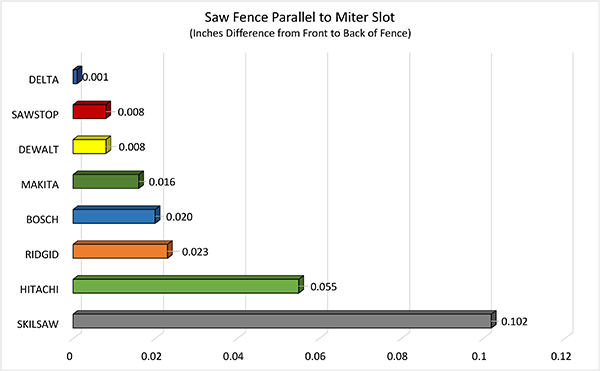

Saw Fence Parallel to Miter Slot

The accuracy and safety of any given saw is dependent upon the blade being parallel to the rip fence. Since we tested the amount of difference in parallelism between the saw blade and the miter slot in the previous test, we need only to see if the miter slot is parallel to the rip fence to see if the saw has a parallel relationship between the blade and the rip fence.

TBB used the same iGauging 35-125-4 digital dial indicator to measure the accuracy of the as-delivered factory fence to the table miter slot. We started by placing the fence in a locked position about 1” away from the blade on the opposite side from the miter slot. We adjusted the throw of the dial indicator so that we took the readings on the indicator, as before, in the middle of the indicator’s range of movement.

We calibrated the iGauging dial indicator to a zero reading at the operator’s end of the rip fence so that we started out with a reading of zero. Next, we positioned the dial indicator to the rear of the saw placed onto the rip fence and took the reading.

If the fence and the miter slot were closer together at the rear of the saw, the dial indicator has a negative reading. If the blade and the miter slot were father apart at the rear of the saw, the dial indicator showed a positive reading. A negative reading meant that the materials being cut might be subject to being pinched and a kick back more likely to occur.

Remembering that a sheet of paper is approximately 0.004″ thick, the results show that the Hitachi and Skilsaw factory settings need some adjustment for better accuracy.

Blade Runout

Blade Runout

One term you may hear when reading about table saw accuracy is blade runout. Runout is a term that describes whether or how much the outside edge of a saw blade wobbles while being held by the motor shaft. Sometimes, operators measure runout by using a saw blade. In that case, the very use of a saw blade presumes that the specific blade is perfect or nearly perfect in its flatness. Using a saw blade that has any warping will not give a clear indication of blade runout.

To ensure that our runout measurements were accurate, TBB used a Freud calibration plate. Freud manufactures this ground stainless steel plate to a tolerance of ± .0005 inches in flatness across the plate. While TBB does not have a means to measure the accuracy of this specification, we did put this calibration plate on top of a polished granite calibration table and could not shine a light under any portion of the plate or slip the 0.001 feeler gauge under the edge.

We used the Freud calibration plate on each of the test saws to measure runout. We removed the new Diablo blade, installed the calibration plate, and raised the trunnion to its maximum vertical adjustment. Before measuring the runout, we placed a black mark on the calibration plate to give a consistent starting position for the runout test. The same iGauging dial indicator provided the test measurements, only this time, the units were set to read out in mm. TBB noticed that in the initial saws, the movements were sufficiently small to need the smaller metric units.

TBB placed the dial indicator on the starting position of the calibration disk and calibrated that position on the dial indicator to a reading of zero. We were very careful to rotate the calibration plate by using the outside rim so as not to impart any side-to-side force on the plate that might introduce errors into the measurements.

While we rotated the plate, we recorded the maximum reading on the dial indicator. We validated each maximum reading by running the test for a second time and noting that the readings were consistent. TBB also noted that as we performed these tests on all eight saws, the maximum readings occurred at different parts of the plate along its rotation. Because the max readings were in different and discrete parts of the calibration plate, TBB had a very high level of confidence in the flatness of the calibration plate, itself.

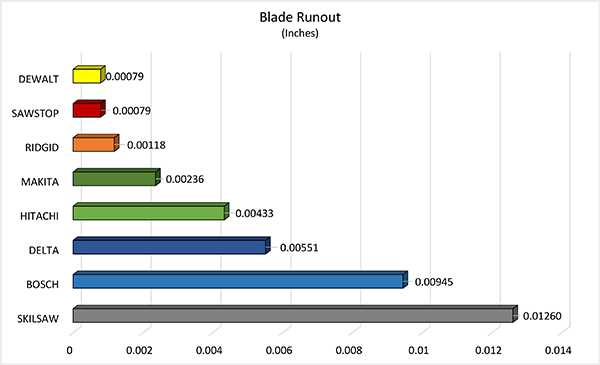

As you can see above the runout ranges from 0.00079 for the DEWALT and SawStop all the way up to 0.0126 for the SkilSaw. Typically values below 0.005″ are considered very good. Both the Bosch and SkilSaw are in a range that needs further evaluation especially if the saw is to be used for finish work.

Precision Summary – Winner SawStop JSS-MCA

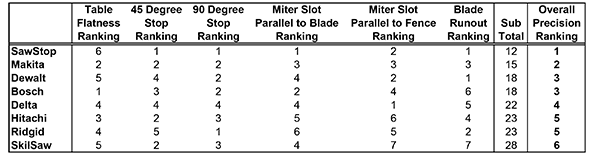

From the data of the six individual tests above, we compiled a summary ranking for the overall winner of the as-built accuracy. The ranking for the summary follows:

The winner for the as-built precision and accuracy is SawStop, followed by Makita in second and Bosch and DEWALT tied for third.

We took the time to measure the as-built accuracy of these table saws. Why?

As we said in the beginning of this section, many of these saws will be used, right out of the box, for rough cutting materials and the fine accuracy may not matter so much in that application. If this is the case for a saw, the quality of the cuts and more importantly, the potential safety of the operator is going to be a function of the as-shipped accuracy of the saw from the manufacturer. So, TBB wanted to see how the various saws compared right out of the box. The results are in and, as a group, these eight saws measured up quite well for out-of-the-box accuracy.

It should be noted that all of the saws were adjusted after the accuracy evaluation prior to the performance testing. With the exception of blade runout the other adjustments can be made to dial in the saws.

Portable Jobsite Table Saw Performance

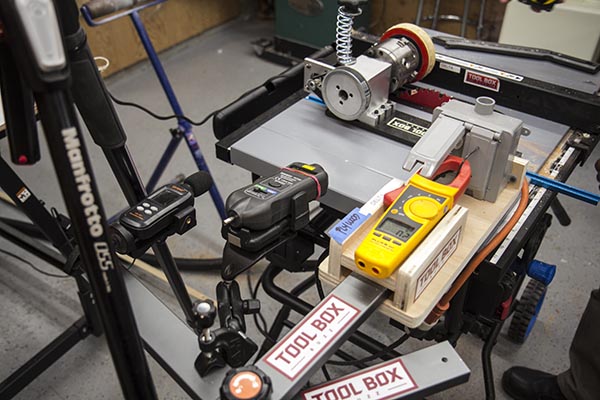

For this portion of the testing and evaluation we used three different materials (3/4″ AC Plywood, 5/4 Mahogany Decking, and 5/4 Pressure Treated Southern Yellow Pine Decking) while measuring the saw blade RPM, and the saw motor AMP draw. To compare the saws we’re looking for how much blade speed each saw has under load, and also how much the amp draw increases under load. Think about it like driving a car, a more powerful car will not drop as much speed going up a hill and the engine won’t work as hard.

We also measured the decibels during the test. We are including in our ergonomics section.

Blade Speed (RPM)

Blade Speed (RPM)

The first measurements we looked at with the performance testing was blade speed cutting all three of the test materials. This tests gives us a relative comparison of how much blade speed reduction the motors have under different loading conditions. In our opinion this gives us an idea of how strong the motor/gear box combination is for each saw. For each test we also recorded the “no-load” speed to capture the relative drop in rpm in the blade speed while cutting wood. We used our as-measured no-load speeds instead of the published values from the manufacturers.

In order to measure the blade speed we used a digital laser non-contact tachometer. A piece of reflective tape was adhered to each saw blade just behind the carbide tooth, so that the tape would be just above the top of the wood cutting surface, allowing us to capture the blade speed during the cuts. We used a power-feeder to ensure that all the material was pushed through each saw at the same feed rate. In the photo above you can see our test set-up with the power feeder, a decibel meter to the left, the digital tachometer in the center, and the amp meter on the right. If you look really closely at the saw blade, the piece of reflective tape is to the left side of the blade near the power feeder.

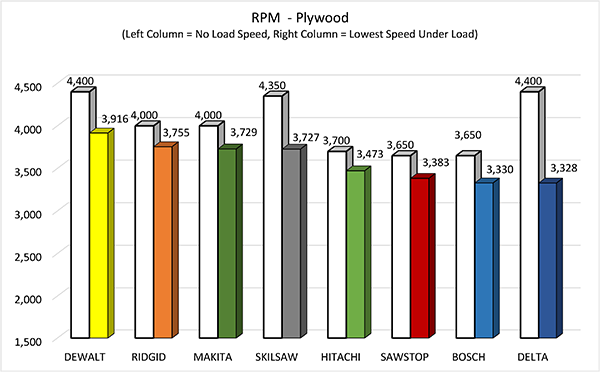

Above are the results for RPM Blade Speed while cutting 3/4″ plywood. In the left column is the no-load blade speed and the right column is the lowest recorded blade speed during the cut. The drop in blade speed is fairly small ranging from 6% for Hitachi and Ridgid, 7% for Makita and SawStop, 9% Bosch, 11% DEWALT, 14% SkilSaw, and 24% for the Delta.

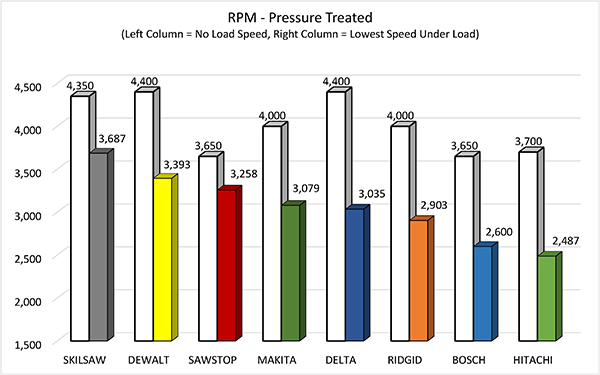

In the next test we measured blade speed cutting 2x pressure treated Southern Yellow Pine decking. In this test the lowest blade speed drop was 11% for the SawStop, 15% SkilSaw, 23% DEWALT and Makita, 27% Ridgid, 29% Bosch, 31% Delta, and 33% for Hitachi.

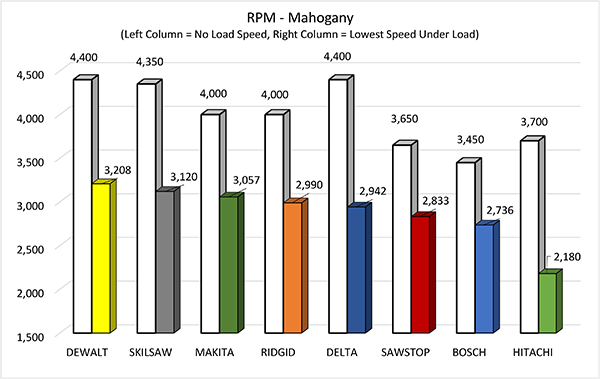

The last test was using 5/4 Mahogany Decking. This was an even more extreme test with the lowest blade speed drop going to SawStop at 22%, 24% Makita, 25% Bosch and Ridgid, 27% DEWALT, 28% SkilSaw, 33% Delta and 41% Hitachi.

Saw Blade Speed (RPM) Summary: The table saw with the lowest average drop in blade speed for each of the tests we performed was the SawStop. Coming in second place was the Makita followed by Ridgid in third, Bosch and DEWALT in fourth, SkilSaw in fifth, Hitachi in sixth, and Delta in seventh place.

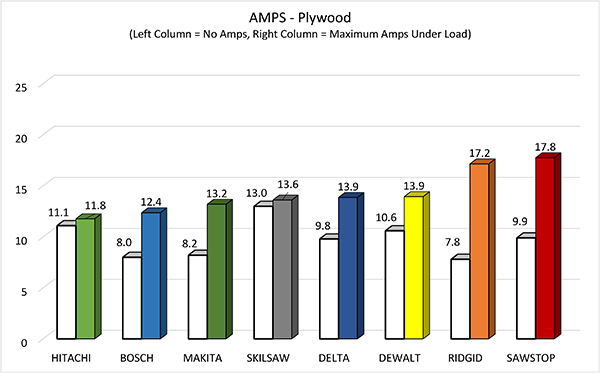

Motor AMP Draw

Motor AMP Draw

Another indication of how hard a table saw is working is monitoring the amperage (AMP) draw under loading conditions. We measured the amp draw for each saw using all three materials again at the same time we were recording RPMs. The first graph below shows the amp draw for each saw cutting plywood compared to the no-load amp draw. The white bar on the left indicates the no load amps and the colored bar on the right shows the maximum amp draw during the cut.

For this test the SkilSaw had the lowest increase in amp draw at 5% followed closely by Hitachi at 6%. The rest of the saws had fairly significant increases in amp draw with DEWALT at 32%, Delta at 42%, Bosch at 55%, Makita at 61%, SawStop at 79% and Ridgid at 120%.

For this test the SkilSaw had the lowest increase in amp draw at 5% followed closely by Hitachi at 6%. The rest of the saws had fairly significant increases in amp draw with DEWALT at 32%, Delta at 42%, Bosch at 55%, Makita at 61%, SawStop at 79% and Ridgid at 120%.

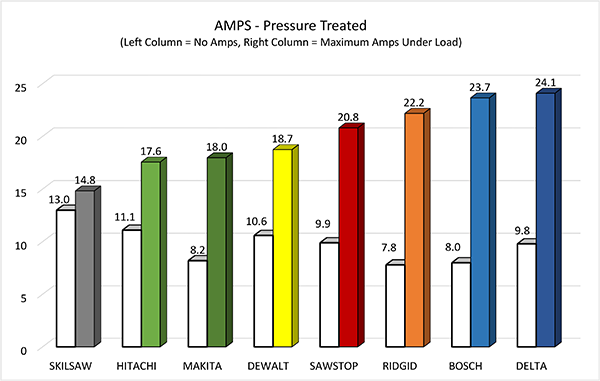

The next graph includes the results from the pressure treated framing lumber.

For this test SkilSaw finished in first with the lowest increased amp draw of 14%, followed by Hitachi at 58%, DEWALT at 77%, SawStop at 110%, Makita at 119%, Delta at 146%, Ridgid at 184% and Bosch at 196%.

For this test SkilSaw finished in first with the lowest increased amp draw of 14%, followed by Hitachi at 58%, DEWALT at 77%, SawStop at 110%, Makita at 119%, Delta at 146%, Ridgid at 184% and Bosch at 196%.

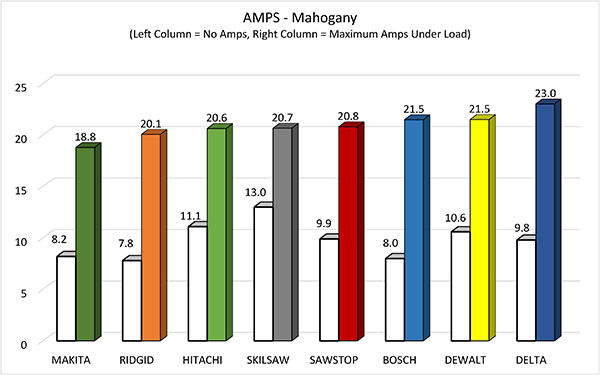

The next graph includes the results from the 5/4 Mahogany decking.

Again we saw the SkilSaw record the lowest increased amp draw at 59% followed by Hitachi at 86%, DEWALT at 103%, SawStop at 110%, Makita at 129%, Delta at 135%, Ridgid at 157% and Bosch at 169%.

Again we saw the SkilSaw record the lowest increased amp draw at 59% followed by Hitachi at 86%, DEWALT at 103%, SawStop at 110%, Makita at 129%, Delta at 135%, Ridgid at 157% and Bosch at 169%.

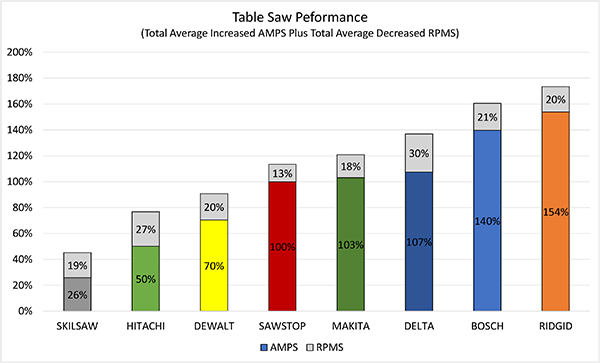

Performance Summary – Winner Skilsaw SPT99-12

We took all of the data from the RPM and AMP measurements and added them to come up with the final performance rankings. For each saw we added up the total percentage decrease in RPM’s (for each material type) and added that to the total percentage increase in AMP’s (for each material type). This gives us a relative comparison of each saw over all 6 sets of data.

The best overall performance in our testing was the Skilsaw SPT99-12. The Skilsaw was described by many of the TBB crew as a beast and the data reinforces that. Regardless of the type of material the Skilsaw SPT99-12 offered the lowest drop in RPM’s and the lowest increase in AMP draw. Following in second place is the Hitachi C10RJ and the DEWALT DWE7491RS in third place.

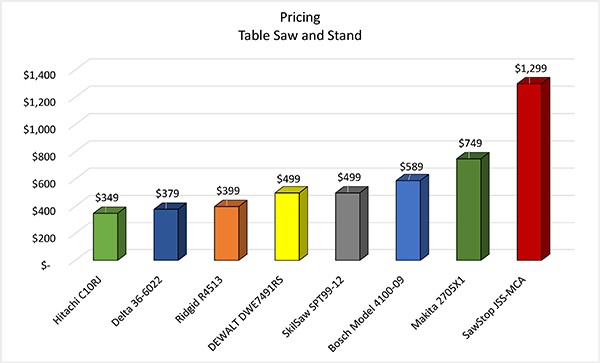

Portable Jobsite Table Saw Price

Below we’ve included the current pricing (at the time of publishing this article). Pricing includes the cost of the stand and ranges from a low of $349 for the Hitachi to a high of $1,299 for the SawStop. The lowest price isn’t always the best in our opinion, we’re looking for the best value. The Hitachi is an incredible deal at $349 and our top pick for price and value for a saw that has lots of power, a rack & pinion fence, and a solid stand.

Another really nice value is the Ridgid that’s currently selling for $399 including the stand. Lastly, it’s hard to ignore the $499 price tag on the DEWALT which is a great contractor grade saw with great features, a great fence, and a really good stand.

Price Summary – Winner Hitachi C10RJ

Buy Now From Our Sponsored Retailers

Portable Jobsite Table Saw Ergonomics

Ergonomics is the science of designing and producing tools that improve a worker’s efficiency while reducing discomfort, fatigue, and risk of injury. Ergonomically enhanced tools can include helpful features such as angled handles, riving knives, safety switches, and non-slip coatings. Whether you’re shopping for ergonomic tools or just trying to select the right one for the job from an existing collection, the key things to consider are whether or not the tool eases your work and prevents you from straining in ways that could lead to injury. Ergonomic guidelines in tool design can help maximize human performance on the job by making the job easier for the worker, improving safety and decreasing injuries.

For this ergonomic section, we considered the following factors, rating them 1 thru 3. [1 being best]

- Weight (Tool and Stand)

- Power Switch location

- Accessory Storage

- Fence

- Adjustments of Riving Knife

- Guard

- Stand

- Ascending Stairs

- Stand Leg Adjust

- Height

- Decibels

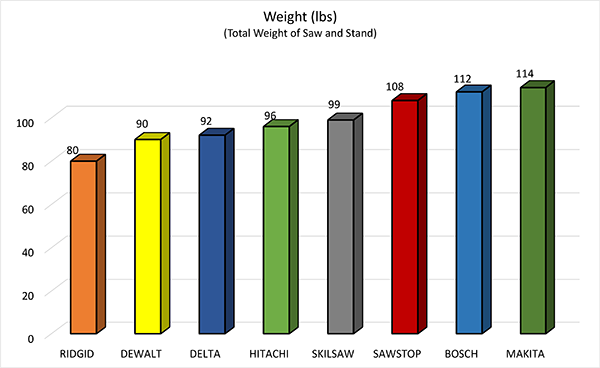

Below is a graph showing the weights of all the table saws including their stands. The saws/stands range from 80 lbs with the Ridgid up to 114 lbs for the Makita.

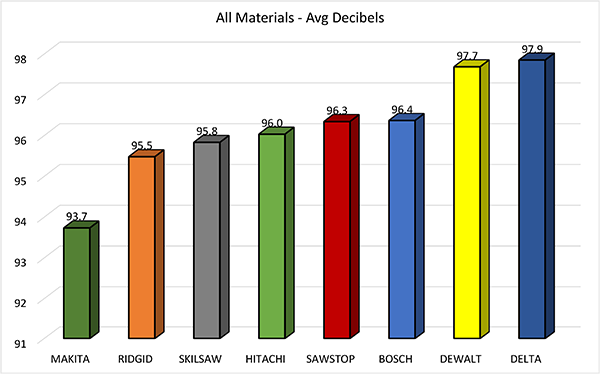

Below is a graph showing the average measured decibels for the saws (for each of the materials we tested). As you can see the saws range from 93.7 db to 97.9 db. OSHA allows 8 hours of exposure for up to 90 db, from 95 db up the exposure limits start dropping quickly starting at 4 hrs for 95 db so clearly these saws all need hearing protection. The Makita was given the best score of 1 as it was considerably quieter than the remaining. DEWALT and Delta were ranked worse with a score of 3, while the remaining were ranked as a 2.

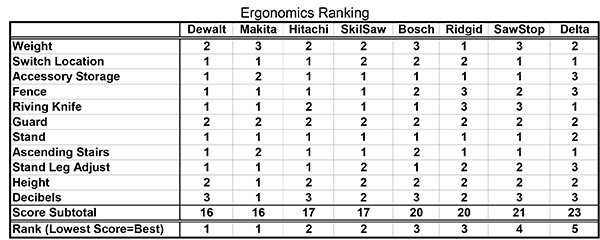

Our TBB crew all helped rank each of the table saws for the ergonomics categories that we defined. Below is a table showing the ranking for each category and the final ranking. An interesting note about the stand height. The crew felt they were all decent heights but the Makita offers several heights which is a really nice feature!

Ergonomics Summary – Winners DEWALT DWE7491RS and Makita 2705X1

The DEWALT and Makita finished in first for our ergonomic rankings followed by a tie for second between Hitachi and Skilsaw and a tie for third place by Bosch and Ridgid. Both the DEWALT and Makita built their saw with the professional contractor in mind. Overall the entire crew really likes the saws with a rack-and-pinion fence system and the large wheels on the Skilsaw were also a big favorite.

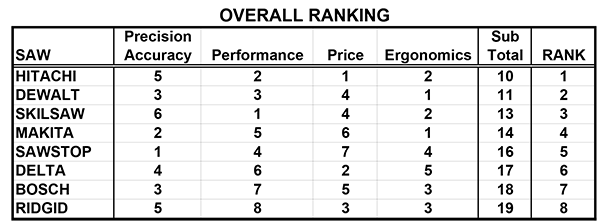

Best Portable Jobsite Table Saw – Winner Hitachi C10RJ

Choosing the best portable jobsite table saw wasn’t an easy task but we’re confident we’ve done a thorough evaluation. In a very close race for the best table saw Hitachi beat out the DEWALT which came in second place followed by Skilsaw in third and Makita in fourth. It’s very interesting that the Hitachi and DEWALT look extremely similar. Hitachi edged out the DEWALT in performance and price resulting in the final scores. Skilsaw beat out Makita for the 3rd place only slightly and that result is really a function of pricing.

It’s interesting to note that if pricing was taken out of this evaluation the ranking would have been: DEWALT in first, Makita in second, Hitachi, Skilsaw and SawStop tied for third, Bosch in fourth, Delta in fifth and Ridgid in sixth place. But at the end of the day price is certainly a factor. What we didn’t do in our evaluation is any long term testing to look at durability which ultimately could affect your purchase decision as well.

We really should point out a big deal here and that’s the SawStop. It’s hard to put a price on safety and while the SawStop costs more than 3 times what the Hitachi costs it does offer safety that no other saw in test can offer. For those that can afford the additional cost that feature alone may tip the scales for you. Regardless of price SawStop came in 5th place for the categories we evaluated.

Final Thoughts

These tests and evaluations are very difficult, take a lot of time, and ultimately limited in scope as we’re not a professional testing company and we’ve got limited time to evaluate the tools. We cannot do longer term testing that would shed light on durability and we can’t possibly test every application that you might use of one of these saws for. However, we feel comfortable that all the table saws in this Head-to-Head are good saws and our testing helps bring to light pros and cons for each saw.

Ultimately everyone needs to choose a tool based on their specific needs, uses, and budget. With all the data above we’re very confident that all of you can make a better educated decision when you buy your next portable jobsite table saw.

Buy Now From Our Sponsored Retailers

Best Portable Jobsite Table Saw Head-2-Head Video Review

About the author

181 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

I really do like your site and being on Long Island there is a familiarity to the way y’all work. You are quick to respond to comments and put in a great effort but…. This review I feel you miss the mark. Out of box accuracy is important but. Ore important to a pro user is tool able to be adjusted to be near perfect and how does it hold this position. No comments on how solid the fences are, ie deflection movement, ease of micro adjust, etc. all the fancy self feed stuff etc, what saw feels the most powerful? Smoothest ? All theses kizmos are for the manufacturers to hype. Your strengths are that you actually use these machines, so your strengths are to BE MORE opinionated or biased not less because your opinion has meaning or weight. Let the know knowings use the kizmos and just give us your real opinions based on real use. Just my 2 cents.

Bengt – We appreciate the feedback as it always helps us get better. Having said that I think some of your concerns were evaluated and included in the results in ways that may not be entirely clear. We adjusted each saw after checking the blade/fence measurements and had no issues getting them adjusted (I may add some text to reinforce that in the article). We don’t do long term testing in this type of article as it’s simply not feasible…so making a statement about whether the saw holds those adjustments isn’t feasible. We evaluated the fences and ranked them in the ergonomics section, we even did lateral load testing on them as part of that ranking.

These tests are so “big” that it’s hard to test every last variable. We feel strongly that motor power is very important in a jobsite table saw and it was a big part of our evaluation.

At any rate, we appreciate the input and hope we can keep you interested in our future testing.

Todd: Thank you for your 2018 Job Site Table saw review. Do you happen to have dimensions of each saw in their folded down (transport) positions? We often haul these in our pickups with tonneau covers, so it’s good to know if they will fit under the cover… We are currently looking to purchase an addition portable table saw and have found it hard to find these dimensions.

Mike – Unfortunately I don’t have that data.

Wow. Great testing work. Is that power feeder available to buy? If so

where?

Thks

Rob

Rob – One of the guys on our crew, Stan, built that for this testing. We had to create something custom to work with the jobsite saws.

I almost bought that hitachi until I looked at it in Lowe’s and some of the parts were broken off on the display model. It’s obviously a cheap copy of the dewalt. I don’t think it would hold up well long to long term professional use

We’ve been using it on the job….so far so good.

No issues with the motor soft start? There is a recall on that and the parts are backordered for months. I bought one for my nephew. He used it a few times and had this issue.

Which saw?

Great job with this testing. As far as the Hitachi. Many sources online point to minimal startups of the Hitachi c10rj before becoming unusable (not starting). The soft start module apparently doesn’t hold up. If it happens in 30 days it can go back to the store but after 30 days you call Hitachi (most described as unpleasant) drive to your closet Hitachi Service center and wait (up to months). I really like the Hitachi myself but am afraid of the soft start module error. THANKS FOR ALL THE GREAT WORK AND CONTENT. Please forgive any punctuation etc. This is tough on phone.

We haven’t see this issue, we are aware there was a problem with early production and they are trying to resolve it with everyone.

Hitachi model.

Note that Todd.took the time to respond to a vague question from PearlGirl. For all of us, and not just for this site, but if you’re going to ask a question you could at least have the decency to check back and see if it was answered. While a response was given to Todd, jt wasnt until 2 weeks later.

Those of you who sell on line know that the very uselss question, “Is it available?” Really means……”I dont really care, but I want to feel like I am able to buy this” and/or “I am really bored and I want to ‘talk’ to someone.”

Responding “yes it is available” is met with crickets 99.9% of the time. I answer “why do you ask? An offer will also answer your question.” It only makes sense to ask IIA? if you are wanting to make an offer. So, anybody who really wants is does what? Yes…they make an offer. If they dont want to buy it, they ask IIA?

But I digress. Thank you to Todd and crew for all of this evaluarion. For those of you with heavy critiques, I suggest you take a pen and paper and start thinking about how many men and how much time and how much money all of that testing would take not to mention experience in the trades. We are spoiled. Years ago, the only way to get this information would be to go around and buy beers for contractors after work and ask them about their tools. Out.

Sadly, the Harbor Freight offering wasn’t released at the time of this “face off”, be interesting to see how it would fare.

Alan – Honestly, we will likely never include HF tools in our evaluations. I myself many, many years ago used some of their stuff when I was first starting out and it served a purpose. But for us their products just are not up to a level we feel warrants our evaluations. I don’t see that changing anytime soon.

Todd, Thanks for your frank and straightforward reply here. I too have used Harbor Freight tools from time to time. I invariably regret the purchase. Okay for a one-time use, but not otherwise worth the investment.

BTW – These product reviews were very helpful for me; I’m currently advising a relative who’s making the jump into a woodworking retirement hobby.

Thanks Larry!

The Harbor Freight Hercules line is a DeWalt clone – I think they have one of their old engineers designing them. You should think about re-evaluating your position. I would agree with your position prior to about a year ago when they started launching these new lines – you should take another look.

Maybe at some point but I don’t see that happening anytime soon. Appreciate the feedback.

Just found your YouTube channel, and I’m so impressed with your thorough testing and documentation. Thank you! Now, one minor disappointment… I too had heard that pro’s were starting to trust the new Hercules table saw from HF. Seems like others here heard the same. I think it would be so cool if you could put this rumor to bed.

Mike – Thanks for the kind words. As I’ve said many times we are not likely to do any HF reviews anytime soon. Just doesn’t fit into our “model” of reviewing tools we use primarily on the jobsite.

+1 for looking at Harbor Freight. They’ve hurt themselves with a legacy of cheap tools – but they have new lines for almost all power and air tools that are really top-notch stuff. If there’s a store near you (and they have them almost everywhere now) I’d encourage you guys to drop in and have a look – you may change your minds. It’s not all cheap garbage anymore….

Just stay clear of that store completely. Unless you want to purchase a tool over and over. Just spend the money up front and buy a quality tool.

I was hoping to see the JET in there. But glad you didn’t waste your time with it. I bought it a year and a half ago and it’s a piece of crap. It has not held up at all, I keep it in my construction trailer and it has its own cubby hole and is secured with straps. It has fallen apart. The fence has no adjustments and is off 1/4” front to back, From the factory. I have to spend so much time trying to adjust rip fence, and then I can’t turn my guys loose with it because they won’t take the time to adjust and check for accuracy. Just really disappointed in the product. I am waiting for the testing done on the cordless saws because I am upgrading.

These are quality tools and I have check some of the table saw carefully and really these look durable and I wish I will buy one from the list. Thanks

On the Hitachi as it sat in the Lowes showroom I was able when locked to move the fence. I ultimately bought the Dewalt on the rolling stand. I recently bought the $299 Ridgid as a secondary saw but returned it due to the blade defkection.

thanks a lots for yours works ,it is great to see the real comparing on tools when I need o buy one ,as it newer end story if you are builder thanks again

Lowes had a Father’s day sale, on their Kobalt table saw with a folding/rolling stand and was $180.00, with more money off because I signed up for their credit card-so I bought it. It cuts fine, the fence locks on both ends,measurements seem ok, and it unfolds and rolls away very easily-I like it so far. I’m a home owner and I use it sporadically and treat it well, it does not appear to be very robust, so as a day to day, on the job site saw, probably not a good choice. I used to have a Makita table saw, with a terrible fence, unreliable ruler markings, and difficult to use blade guide that interfered with measurements, which you needed to do every time-a terrible saw, very frustrating to use. I have a Makita miter saw and it’s great, but the idea of buying a same brand because I liked one of their other products did not work out.

I found this by accident. Very informative and a wealth of knowledge. I hve often wondered how each of these saws compared to the others.

I was lookng for Fence accurracy, maybe you covered it, I will have to reread the artice to see. For me this is very important.

Thank you.

Thanks for the excellent article, and the video as well. I’d be glad to see a list of the testing gauges and other instruments used. Some of these might be good to have to do initial and maintenance setups.

Really well done, thank you! This is a very thorough comparison.

One of the best tool reviews I have ever seen. Actual measurements and not just a bunch of opinions. Especially liked the measurements of speed and amps under load. High amps not only trips breakers but also overheats the saw.

Hello,

the AMP draw table is strange.

Why is it good if a table saw draws the same power with no load and load?

Isn’t it better if the saw draws less power if it’s now under load?

First you save energy and costs if the saw is running a long time.

Second the motor dows not run at max power all the time an therefore might last longer

I submitted a fairly detailed comment about:

– the great tests and reviews here, including this one,

– reminding folks about how accuracy is specified,

– the possible over-resolution of some of these measurements, and

– raising some questions about the accuracy (precision) of some the angle and length measuring devices.

That comment has not (yet) been published.

Sorry Todd usually does the approving and he’s on vacation. ~ ROB

[…] Best Portable Jobsite Table Saw – Head-To-Head […]

I was very impressed with the math that you used in your testing….. for me it’s reasonable accuracy out of the box and a rack and pinion fence.

At the end of the video you talked about longevity…. longevity is very important to me in a tool….. so maybe you can help me out with this one and tell me where I’m wrong.

Quite a few years ago I learned to take the 10 inch blade that came with a Sawzall and either throw it away or give it to somebody who wants it more than you. And replace it with a 7 in 1/4 Diablo blade….less noise…less money….less saw kerf marks in the wood… glassware on the motor… along with less vibration.

You can still cut inch and a half stock but most of us are using three quarter to begin with….for me this adds up to longer life of my saw….please tell me your thoughts.

Bob – Thanks for the compliment. I know LOTS of people run smaller blades but I’m not sure the smaller blades are really designed for the slower speed and increased torque. You can get decent 10″ blades that are not horribly expensive. Just my 2 cents 🙂

The level of detail on performance is really great! I’d love to see more detailed feedback on the fences and stands.

Patrick – Thanks for the feedback. Trust me, I wish we could spend more time on every aspect but we spent hundreds of hours as it was. I can tell you that the rack and pinion fences are much better than the standard fences of the past. Our entire group felt strongly that we’d prefer the rack and pinion on all the saws. We felt the Ridgid and Delta fences were the least impressive of the standard type.

When it comes to stands it’s a much harder conversation. The new Makita stand is really nice because it has adjustable heights allowing for user preference. Having said that, we all really like the style that Dewalt and Hitachi use. The new Skilsaw stand is great for mobility with the big wheels. I hope that helps a bit.

Amazing information thanks a lot for this Demo! Very well put together guys!

Very well written article with full information. Thank you for sharing this great info. It’s nice to know and read about this stuff. I would definitely try to follow these suggestions.

Excellent review with great detail and valuable information for the amatuer buyer who is just getting started with wood work. THANKS and keep it going!

The “Saw Fence Parallel to Miter Slot” text states ” . . . the Hitachi and SawStop factory settings need some adjustment for better accuracy.”

But the data in the table suggests you may have intended to reference the SkilSaw (rather than the SawStop) in that text (or in the table?) for that issue. Which is correct?

Also, I’m trying to decide between the DeWalt & the SkilSaw if I install on it the Incra TS-LS fence system I have. So, even though you said the table sizes on all of these are similar, I’d really like to know the actual table size, at least of these two, if you hsppen to know it.

And finally, I would appreciate your thoughts/recommendations about choosing between the DeWalt and the SkilSaw based on the assumption that the fence on theone selected will be replaces by the Incra fence & that I will be using an Incra miter gauge ((VS120) with it (instead of the supplied miter gauge)?

Thanks.

Paul – Good catch….I’ve updated that to say Skilsaw not SawStop…thank you! As you can imagine…all the data makes it tough to keep it all straight. I’m not even sure how you’d install that aftermarket fence on these saws. If you do I’d love to see how!! Those really look like they are made to install on cast-iron full size saws. I’d choose the DEWALT with a slight edge over the SKilsaw.

Nice comparison overall. Interesting to see the wide range of amperages in both no-load/load conditions. Were these from a single cut, or averaged from multiple? Noted that the no-load amperages changed from one set of data (cut-type) to another for some of the saws. Typo or indicator of something else varying?

Also, any thoughts/assessment on whether the saws’ weight might be indicative of more metal than plastic in its construction. Unfortunately, light weight can sometimes mean lower build quality.

totally agree – but todays ABS plastic is pretty durable. I turned 50 this year and really appreciate the lighter weight tools

A question: why the no-load speed for same machine is different in different table? for example:

RPM – Plywood: Ridgid 4350; Hitachi 4400

RPM – Pressure Treated: Ridgid 3650; Hitachi 3700

A 50 rpm deviation at those speeds is approximately 1% variance which is well within the tolerance we should expect from taking the readings at a precise instant of time. The meters were in constant motion and we took the reading off of a single video frame that represented our determination of no-load speeds. We report them as our instruments showed them. 1% is acceptable.

Rob, thank you for the explanation. But my question the same machine have significant difference – for example Ridgid, the no-loading speed is 4350 for polywood but 3650 for pressure treated wood. It’s 700RPM difference, more than 10% variation.

Jeffery – As Rob explained things we had the RPM measurements running on that meter, and had to watch our video playback to evaluate the numbers (no recording of the numbers digitally). So we tried to take the average no load speed watching the video play back. Is it perfect? No….is a 10% difference a big deal? In this application I doubt it. If we were a full blown testing lab we’d have the data recorded digitally and take full blow averages, but alas we are not.

I really enjoyed your review and appreciate the significant time and effort put into it. How did you acquire the machines? Were they evaluation units provided by the manufacturers or did you buy them (randomly, like Consumer Reports)? If they were provided to you the cynic in me says you probably got cherry picked units. In looking at the various machines on line and checking out their comments, it’s quite clear pretty much all of them have a manufacturing distribution of performance and metrics e.g. for accuracy all the units you tested have comments ranging from great to truly awful. Same thing for build quality. I spent quite a while looking at the Dewalt but all the negative reviews on quality and accuracy turned me off it. I certainly do see many more positive reviews than negative reviews for the Dewalt, but it does leave you with the feeling that a dice roll is partly involved in buying a recommended table saw.

These table saws are all probably made in China where there’s apparently no meaningful out-going quality control. While the *average* quality from a given manufacturer might be great, you could also be unlucky get a piece of junk because *everything* made on the production line ships out. It’s a preferred business model these days – the prices are much cheaper but the manufacturers trade that off against dealing with significantly increased returns and the need for much more customer service.

Having written the above, I really don’t know how you might possibly respond – other than for you to say I’m ranting (which I think I am).

You guys didn’t mention the most important thing on my list. DUST COLLECTION! This is super important for guys cutting parts in a 1 car garage. Next to the job site a garage is next most likely place for these small saws and dust is a huge issue.

Great reviews.

I was wondering if there will be any followup now that you’ve had a chance to use the saws for a few months? Especially interested in how you’re finding the Hitachi is holding up. Was ready to pull the trigger on this saw but there seems to be a lot of negative info out there concerning the fence lock breaking and the saw motor failing to turn on.

We’ve got guys using the saws in the field…so far no issues. If something comes up we’ll post an update.

Sadly, anything Hitachi anymore is poor quality.

I got the Hitachi 1 1/2 mouths in the motor died. Says it has a 5 year warranty. I’ve been trying for weeks to get it resolved. Ended up giving up and headed to buy another saw. I understand having products be faulty it’s a numbers game it has to happen to some one. How ever the complete no help to resolve it from Hitachi. Is a problem after a week of back and forth they said they would set up a pick up time to ship and get it repaired over a week still no call back for a pick up. I can’t say enough avoid this headache. I’ve been a contractor for a decade and have had may tools break or need repair. First experience I’ve had that’s made me swear off a brand.hope this will save some one from wasting money and time

Really informative and thorough review. I’m leaning towards the Skilsaw now. I like that it’s able to rip/crosscut 4x4s in one pass, and the rack and pinion fence. I’ll just make sure to fine tune it first.

One thing worth pointing out is that Ridgid, at its low price-point has a lifetime warranty. My miter saw is a Rigid and it’s a beast.

Have you guys looked at the Menards “Masterforce® 10″ Jobsite Table Saw” I’m curious about that one as it seems to have good specs at a great price.

Very cool video!

I’m looking to pick up my first table saw a few future projects around the house.

I’ve been looking at the Hitachi C10RJ at Lowe’s. I like the safety features on this as I do not have any

experience on one. I was glad to see that the Hitachi did so well in the head to head.

So I’m just wondering if this Hitachi table saw be a good saw for the beginner?

Yes it will certainly be a great saw for anyone including beginners.

Todd – Really great review.

Two questions:

1. Is it possible that the SkilSaw SPT99-11 and SPT99-12 have the ability to accept up to a 13/16″ dado set instead of just the 1/2″ max your review states? I have seen the larger spec stated elsewhere. If not, why? Is the arbor just not long enough? Or is it a zero clearance plate problem? I can’t imagine having to do two passes to complete a 3/4″ dado. The 1/2″ max seems a weird anomaly as compared to all other saws in the class.

2. The two models I mentioned above appear to only differ in the type of blade included. Your team tested the second model, which I think comes with a premium Freud Diablo blade . . . but what is its model # or exact description? Also, the model you did not test comes with a Skil blade, but again, I cannot find its description anywhere. Can you help by supplying its model #. ??

Dave – let me do some investigation and get back to you.

Todd –

I discovered an online manual for the SPT99-12 and was able to ferret out the answer to my first question, above. On page 46 of that manual, these words are found:

“The SPT99 table saw can accommodate dado cutting up to 13/16″ wide in a single pass. WARNING -To reduce the risk of injury, always disconnect plug from power source before changing blades. WARNING – To reduce the risk of injury, always use the Skilsaw SPTA70WT-DD 1/2 inch Dado Blade Table Insert or the Skilsaw SPT00A 13/16 inch Dado Blade Table Insert (both include dado accessory washer). Never make dado cuts without this insert. Do not use dado sets larger than 8″ diameter.”

I have learned that even though the insert part number is in the manual, it is not being sold yet, but is expected to be on the market soon. That explains why SkilSaw put on their website (though misleadingly) the spec that says that the “maximum acceptable dado set thickness is .5″ ” It is about the table insert, NOT about the arbor length.

So that solves that question. I still need an answer to my second question, though, as well as your opinion about which blade model number is preferable and why (or for what).

THANKS!

Dave

Todd –

You need not post this, but I should have suggested in my most recent comment that you might make some sort of notation in your review in the “Saw Features” section to correct the 1/2″ MAX Dado cut width” for the SPT99-12. Maybe restate it to say “13/16″, but presently comes with an insert that only allows 1/2″ ”

Dave

Thanks! Done

Thanks for the work you put in on this. I am retired now and have been researching these types of saws as I wish to begin doing some building of storage shelves and deck furniture. As a beginner, I did not wish to spend huge amounts of money until I was sure it was something I would be staying with for a while :-). Very informative and happy to see the way you did your testing (on the video). I spent 20+ years testing or working with security software testers and totally understand the issues of testing (almost anything) in a fair and honest way. Your work is greatly appreciated!.

Great match-up and informative… however I too noticed that “No Load” RPMs varied quite a bit from chart to chart – for the same saw. We would expect some variation of 50 RPM as you had mentioned, but not 500 to 800. See that the Hitachi changed from 4400 down to 3700, Delta jumped from 3700 to 4400, Rigid from 3650 to 4350. Upon closer scrutiny… the order of “No Load” RPMs used in first chart may have been used in all subsequent charts. When the “Load” results were ordered by hi-to-low ranking, is it possible that the “No Load” data was not kept with its saw? If so, that changes the %drop results slightly for most RPM No-Load/Load,Speed charts. No too terrible. Lots of data… Good overall presentation though for use to make informed decisions. Thank you!

Just in time!!! My Sears Craftsmen portable saw died on me last week. It was only 12 years old with minimal use. It was a nice saw with a nice sized table, not heavy, and a stand that separated and folded like an accordion. Unfortunately, as it turned out, the gear teeth on the worm drive had worn down to the point where the saw started slip and whine. Now that Sears is defunct (Canada), I have no other option than to replace it due to no parts being available.

That said, I have been looking for that ideal replacement saw that will hopefully take me further down the road than the Craftsmen, and a unit that will do what I need it to do. This review could not have been found at a better time. I will take the results that were achieved and use them as a measurement in purchasing a new one. Thanks for the time spent on conducting this testing and review. Very much appreciated!

Good luck Chris!

An idea for next time you do a table saw review – what’s most important to me is REPEATABILITY of adjustments. Same for the fence – I want to know that, wherever I set it, it’s ALWAYS accurate and straight. I’m OK if the saw needs some tuning up out of the box – most saws do – but I really want to know that I can trust the saw to HOLD its adjustments, especially if I’m moving it around a lot. This I find is the weakness of jobsite saws in general – they just don’t STAY accurate for very long as vibration and just moving them around jar things out of position. Essentially, I want to know which of these saws is going to need constant fiddling, vs which ones ‘just work.’ with minimal fuss.

Brad – Won’t be anytime soon. I’d offer a few thoughts though on this topic. First off, for this type of testing it’s just not feasible for us to do any long term testing that would be required to evaluate your concern. You’re right, most jobsite table saws have less than perfect fence systems. The rack-and-pinion style that DEWALT, Hitachi and some others use are far more accurate over the long haul than the “clamp” style. Lastly, for lots of guys they are transitioning to track saws for work that requires a really precise cuts or they cut critical pieces in the shop. In a perfect world we’d get shop precision out of jobsite saws, but the reality is due to weight limits its unlikely. Thanks for the feedback.

[…] Link Sean Mentioned: https://www.toolboxbuzz.com/head-to-head/best-portable-jobsite-table-saw-head-to-head/ […]

I’m looking at buying the DEWALT but one thing worrying me is that the negative reviews on it claim that the table is severely not level or that it is difficult making it level. Did you have any problems with that or do you have any insight into why reviewers are claiming this problem with the saw?

Scott – I’m assuming you’re talking about the “flatness” of the table and not leveling the saw correct? I will tell you that all jobsite table saws use light weight tables that are NOT machined cast iron like shop saws. Most of the jobsite saws are a light weight cast aluminum top, and NOT machined flat. So there are tolerances in the manufacturing that make it impossible to get a really flat surface. The thing is, in my opinion, for this type of saw it’s not really important. Job site saws are set up for ripping framing lumber, trim, and details that are not as precise as “woodworking” projects. If you need a cut that precise on a job then there are other better approaches including track saws and even pre-cutting materials in the shop. The DEWALT is very similar to the other saws with regard to the table.

Todd – Yes I was referring to the “flatness” which some reviewers were complaining about. Thank you for your response. My problem is that I don’t have any workspace in my garage. It is a tiny garage which we use for storage so I need a saw I can store there but will be doing the actual cutting in the driveway so I have to move it out there to cut, then store it back in the garage in a tight space. I thought maybe a job site saw like one of these would work well but I would be making furniture and “woodworking” projects so maybe not. thanks for your feedback.

Have you looked at “contractor” style saws? I had one for years until I upgraded to a unisaw. I put it on a mobile base and it was great. If you have the room that’s what I’d suggest.

Scott take a look at sawstop’s contractor model with it’s mobile base. It has the accuracy of a cast iron table, a great fence and folds up somewhat be like these jobsite saws do.

The safety value of the sawstop is worth the price difference. A friend’s daughter cut of half her hand in a shop accident in her highschool last year.

Take a look at at it

Thank you for your in-depth analysis.

I believe there are errors in your RPM computation charts. You use different values for “no load speed” in each test. For example, for the Rigid saw, in the RPM-Plywood graph you show 4,350 as the No Load Spped; but in the RPM-Pressure Treated graph you show 3.650 and in the RPM-Mahogany graph you show 4,000.

I have a couple questions about your methods and precision. The no-load rpms for the different saws were very different from replicate to replicate for the three different materials. Wouldn’t you expect the no-load speed to be fairly consistent for each saw regardless of which material was going to be used to add load? With that amount of variability in the no-load speed, I wonder how precise any of the measurements were under load?

Also, I’m not sure I agree with how you binned the results for the volume test, because there is one saw that was much quieter than the rest, and one that seemed much louder than the rest, but you only used two numbers per the text of the article. I see three categories at least.

Also in one of the tables above, one of the saws was given a decibel score of 1, while the text indicates none of the saws got a one because they all require hearing protection.

Jason – Thank you along with several others for pointing out this issue. We in fact had some numbers mixed up in the spreadsheets for the no-load speed. We’ve fixed the tables and updated the article accordingly. The changes actually do not effect the final results, but again we’ve updated it and appreciate the effort to point out the mix ups.

Well done review. I have two questions:

1) cut quality – I know blade choice can be a big factor, but was there any difference in cut quality?

2) blade runout – this is important to me because I want to use the saw for finish cuts. When does blade runout become a factor? When it is under load and/or when you push the material too fast? Would a strong motor make up for slightly more run out? Does the momentum of the blade solve that issue while cutting?

Also, how do you fix it? Is it the the bearings, or can it be adjusted? Also, you can buy blade stabilization plates, does that help?

1. We only tested them using all new blades from the same manufacturer to eliminate the blade performance. So it’s hard to say…they all had similar cut performance with good blades.

2. Blade runout really depends on the tolerance you need. Remember, these are portable table saws, not shop saws, and hence they are not designed for “precision” work. The motor isn’t going to fix this. Can it be adjusted? I’m not sure on these models.

hi Todd

thanks for sharing this review and test its really spend many hours from you

i am asking what is your recommended table saw for beginner wood working like me

Well these really are not for “wood working”…really designed for job site use. For a beginner wood worker I’d look at a contractor saw if you’re on a tight budget.

Hi Todd,

To you and your team, this was a great review. Probably the most in-depth I’ve ever seen. If this question has already been addressed, please forgive me. For each of the sections tested, I. E. Table flatness, miter to blade, miter to fence, etc. is there an article or videos you can point me to that shows how to correct each?

Also, you answered a guys question, who was new to woodworking, saying these are job site saws and not for woodworking, and to get a contractor saw. What is/are the difference/s? I am looking to use one for furniture, cabinets, shelving, etc., and want to be sure I make right choice as this will be my first table saw. Budget is not my BIGGEST concern versus getting what is best for what I want to do.

Again Todd, thanks to you and your team, great work!!

Bobby – Job site saws like the ones we reviewed in this article are built “light weight” for portability. They have light weight tables (cast aluminum, thin plate tops). A “contractor” saw is more similar to a cabinet saw and has a cast-iron solid top which is much heavier, and is machined to a very flat surface. A contractor saw is a bit smaller in footprint than a cabinet saw, slightly lighter, and works well on a mobile stand. If you’re building furniture I’d recommend a contractor style saw at the minimum, or if you can afford/have space a cabinet saw. You can see my shop here: https://www.homeconstructionimprovement.com/workshop/ where I use a Delta Unisaw and it’s exceptional.

Absolutely fantastic testing, wonderful, thank you.

The only thing I’ll mention is that you scored all the results as if they were equally important, and that’s ok for trying to arrive at a neutral test. As a reader/carpenter, I’ll mentally weight the results for 2 things:

1) Importance of each test.

2) Special attention to red flags, or unacceptable results.

And so for me, there’s a number of winners to this competition, depending on how one intends to use the saw.

For brute production, lots and lots of rough work, it looks like the DeWalt or Skilsaw is your best bet.

For more precise work, I’d hands down have the Makita. Because while the SawStop performed “better” overall, the table flatness was unacceptable. And where the Makita’s lagged the SawStop, the difference was not actually meaningful. And it’s table was flat.

Mike – Great feedback. We’ve been trying to get guys to look at the results exactly this way. We pick our winner, but we give you all the data so you can make your own choice depending on what’s important to you as a user. Thanks!!

Excellent reviews

Do you know what power output at Watt for Bosch and dewalt

Very thorough I especially appreciate the focus on accuracy and run out. Although, I wonder what the purpose of the coating is on all the table tops? Core Millwork perhaps?

All of the tops are lighter weight materials like cast aluminum and not cast iron. They really need a coating.

I appreciate the response but I seriously doubt that. Mike 30 year old Makita has an aluminum top and is still in service without issue just like my 20 year old Bosch. I don’t know it for a fact but I suspect they do not want to grind the tops smooth anymore. I highly doubt the sprayed coating is tougher than the material under it.

Thanks

Ian – I’ve personally spoken to most of the product managers on these saws. These cast aluminum tops that they are all using is an effort to reduce weight. Every manufacturer is struggling to keep weight down because it’s one of the top factors that users list as helping decide what saw they want for jobsite use. Users don’t want to compromise on size, but they do want lighter weights. The older jobsite versions don’t use a cast iron top so if it’s truly “ground” i’m not entirely sure what it is. Even my older Bosch saws that are over 15 yrs old have a surface similar to these saws today.

I’m disappointed with this review. I think it is an interesting fact contractors buy the saw and set it up at beginning of the job and just use it. But, the precision testing in the review doesn’t answer the best for that purpose. For that purpose, how durable and easy to setup the stand. How powerful for chugging through sheet goods and non-precision work. How well does it handle getting rained on.

The precision tests, were an interesting start. Then, should be followed up with a precision setup. Then, you can give a review which makes sense to an on-site precision built-in construction or a homeowner using for precision woodwork without enough room for a cabinet saw. If the blade is tilted to 90deg 100 times, does it always go back to 90? Does the rest of the setup stay in place? Does the blade height creep? Do the trunions flex and cause un-even cuts? I know it isn’t a cabinet saw, but with the precision measurements, the review can answer what the saw is capable of.

What about design? Are the miter slots T-slots so I can use an incra-miter guage or t-slot based feather boards?

Andrew,

Sorry you’re disappointed. The reality is we have full time jobs as contractors not as engineers in a testing lab. It’s simply not possible for us to do long term testing to evaluate things like you’re recommending. We try to develop tests that we feel would be important in our decision making process on selecting a tool. Are those tests what you might be interested in? Not always, but we provide all our data in hopes that some or all of it will help someone choose a tool that’s best for them. I feel we did provide information on power by evaluating several material types and how the saws reacted with blade speed and amp draw. Thanks for the feedback.

Although I think the above comment was a bit harsh. And am very happy with the depth you have gone to, I would also love to see a followup video with the precision on these saws after having set them up and used them several times. Great job and thanks!!!!

Thanks Vince…..the trouble is this….all of us are full time contractors and it’s a struggle to keep up with all the tools sent to us to test, let alone trying to revisit tools later. Just not at all plausible.

A great series of tests and article. I’m amazed and grateful to read as I am contemplating the purchase of a saw like this. I read the entire article and all the comments.

I’m weighing the pros and cons of several of the saws in the tests and trying to decide which is more suitable.

I’ve used a number of table saws over the years, all old style full sized saws, that were owned by employers usually, but never operated a small saw like the ones you are testing. I recently purchased an older poorly maintained brick building from around 1900 which I am planning to fix and build an apartment in for myself, nothing fancy.

The rest of the space will be an electronics hobby workshop.

The ability to move the saw around on the wheels within the building will be helpful, but once it’s inside that is where it will live.

I like the Dewalt, but I’m concerned about the flatness of the table.

In the article it mentions the flatness, as do many reviews at the HD website. In some cases people who bought the saw returned it because of the flatness issue. It seems to be hit or miss on the flatness one might get in any given table, a random factor. What would be the practical effect of using a saw that had a flatness issue of up to 1/16 across the table?

I don’t anticipate making furniture, but I’m not so willing to struggle with my tools anymore either, as I’m an older guy and a bit crabby! I’d like the finished product of my efforts to be presentable and worthy of the time I put in, and enhance my property value and utility of the building. The bigger factor is going to be my limited woodworking abilities, however I’m willing to pay a little bit more to get a saw that will help me not work against me. I looked at the Delta Unisaw that you referred to in one of the comments, however it seems to be in a different, much larger category. As far as I could tell from reading the article, the flatness of the table is built in to the particular table and can not be calibrated out, is that correct? As I am a homeowner and can take time to make cuts free of commercial pressure rapidity of adjustment is a secondary issue, accuracy is probably my biggest concern. I would anticipate buying a saw using it carefully and not use it up as you mention you do when using these type saws at a jobsite. Any comments are appreciated!

David – Great questions. The real answer to your question depends on what you’ll be building. Any of these saws I’d be happy using to do basic carpentry projects around the house. Ripping down trim, cutting flooring, ripping framing materials, things of that nature. The flatness of the table won’t hamper any of those tasks nor make your life more difficult. If you told me you wanted to build some nice furniture, build decorative 3D cutting boards, things that require greater precision then I’d say these saws are not accurate enough in general, nor set up for that kind of work. There are two extremes, large cabinet saws like the Unisaw, and then small portable saws like these. However, there’s another category in the middle of that called “contractor saws” and there typically have a smaller footprint than a cabinet saw, but they feature a cast-iron top, and work nicely with a mobile stand. They are also priced in the middle of the two other categories. This might be a better option for you. Saws like this: https://www.jettools.com/us/en/c/woodworking-table-saws/180?Series=proshop&Filter=1&reset=true

Hope that helps.

Todd, thank you for the answers, and the link, I clicked and took a look at that Jet saw. It looks like a very nice tool, and something that deserves a dedicated space to be set up in, which I probably won’t have for dust reasons. The projects I anticipate using a saw for probably fall in the realm of basic carpentry projects. I want to put a french door in a hallway to divide the hall for heating purposes. I may put down a laminate floor in one room, and I need to convert a large closet into a room that is suitable for putting a gas water heater in. With modern venting codes that is going to include moving a non-bearing wall. At this same time I am going to replace the steel sheet metal shower stall with a modern stall. I’m hoping to hire someone to replace the shower stall and build a custom stall in the odd shaped space available, however I would not be surprised if there was no one willing to take on the headache, and so may do that myself. The same with a new apartment I would want to have built, I may have to build it myself for the same reasons.

That project would involve putting up stud walls, doorways, a bathroom and a kitchen. There would be some trim work of course but the original building is very sparse and there would be little work that needs to be matched. I may wheel the saw outside to be able to cut out there when practical to limit dust inside the structure. So after looking at the Jet saw and considering the options and work I’m doing I plan to go ahead with the Dewalt saw. The closest HD where I can get it is over 100 miles away (I’m in a small remote town)so I’ll plan to pick one up there, I can select a box that has not been damaged, and avoid potential shipping damage woes.

Thanks again for the tests and your input, it has been a useful education!

Hi,

Thanks for this video and the work you all put in to devising the excellent methodology and running the extensive tests.

I’d would like to import a Hitachi C10RJ from the US to Japan, where I live. Unfortunately, this model is not available here. I know I’ll also need a 1800W (or higher) power converter to step up from the 100V used in Japan to the 120V required by the saw. However, I can only find converters at this wattage that convert to and output 110V. If I used one of these converters, would it significantly underpower the saw or would it work more or less as described?

Hope to here from you soon.

Paul

Paul – Great question. I’m not an electrical engineer so I’m not really sure. My guess is it would be fine. Have you reached out to Hitachi (now Metabo HPT)?

Very thorough review, thanks. I am a diyer, not a pro. In Canada our prices our much different. I am looking in the 300-400$ range. For that price I could get either a small compact saw like the Dewalt DW745 or the Bosch gts1031 or the Rigid R4513. I like the idea of having the saw/stand package that fold in the shop instead of a small compact saw. Is the Rigid a bad saw? Should I get the smaller Bosh or dewalt over the bigger Ridgid?

All three are good saws. If occasional use I think any of them will serve you well.

So my question would be other than the ability to create a flatter surface. Which table saw was able to be perminately adjusted for accuracy? The ability to level table saws was a question I also had, but well not every one considers that to be a significance.

The combination of saw stop for its accuracy and safety, with skill saw power or performance and wheels, Makita for its hight adgustability. I , and the price of the Hitachi I think we would have the perfect table saw.if only

Frank – Like most things in life if we could take the best from each and make our own it would be great! As far as flatness of course non can be adjusted for that. I don’t remember off the top of my head, but the remaining can all be adjusted with regard to the fences. Like many things, these more “compact”, “portable” saws don’t offer all the adjustments that nicer cabinet saws offer.

Ridgid is correctly ranked last, bot for more reasons that is stated in this article. The motor in my Ridgid table saw burned up in less than a year, even though I “babied” the saw. The Home Depot refused to honor the Ridgid Lifetime Service Agreement. Only after I complained to the store manager did they do anything about the problem, by replacing the saw with a new one. Even though I requested a repair, they swapped the saw, and now Ridgid refuses to honor the Lifetime Service Agreement on the replacement. And now, you guessed it, the motor is failing in the replacement saw.

I know of two other people whose Ridgid table saw motors failed within a year of buying it.

This is the fourth Ridgid product that I have purchased, and all of them were defective. If you are a professional tradesman, I recommend never purchasing a Ridgid product.

Can anyone tell me where to get an arbor wrench for the Hitachi C10 FR jobsite table saw ?

https://www.ereplacementparts.com

This is really great article to know about portable table saw. thanks for your nice article. keep it up.

I ended up getting the Sawstop Pro (the newer model) because safety was of paramount importance. But as it happens it is a fine performing saw. The saw was pretty well calibrated out of the box but I fine tuned it a bit getting the blade to miter slot distance to within .004″. And the adjustments are very easy to make and effective. Excellent manual; very little assembly required. The zero clearance throat plate was already cut for the factory blade.. Fence is very good; miter slots are perfectly uniform. It may not be a contractor or cabinet saw but it sure cuts mighty fine. What a sea change from that Ridgid saw which I could never get quite square. What’s not to like except the price? But what price safety?

I ended up buying the SawStop Jobsite Pro (the newer model) primarily for safety reasons. But, putting safety aside, it also performs very well. BTW, the flatness of the top on my JSS Pro is as follows (using the same methodology you followed):

diag lower left to upper right: .028″ (.70 mm)