Skil Benchtop Drill Press Review – Model 3320-01

SKIL 10″ Benchtop Drill Press

SKIL 10″ Benchtop Drill Press

Over the coming month we’ll be reviewing several drill presses on this site and our home improvement site. To start things off we tested a benchtop drill press from SKIL. The 10″ Benchtop Drill Press from SKIL offers home owners, DIY’ers and hobbyist a small benchtop drill press capable of a wide range of drilling projects.

Features

- 3.2 Amp motor

- LaserX2™ 2 Beam Laser System — For precise hole alignment

- Depth Adjustment System — For easy depth control

- Variable speed (570, 900, 1390, 2050, 3050 RPM) — 5-Speed system for different material types

- 0-45° left and right tilting work surface — Precise and accurate angled drilling

- 7-5/8 in. square work surface — Large surface supports work piece

- ½ in. keyed chuck — Accepts larger diameter bits designed for woodworking and cutting

- Adjustable depth-stop — For accurate depth measurements and repetitive drilling

- Bump-off switch — For added safety

Specifications

- 120V, 60 Hz

- 3.2 Amp

- 5 Speeds: 570-3,050

- Chuck Size: 1/2 in.

- Drill on Center: 10 in.

- Tilting Work Table: 0-45°

- Table Size: 7-5/8 in. Square

SKIL Drill Press Model 3320-01 Review

The folks at SKIL sent us their 10″ Benchtop Drill Press (Model 3320-01) to test and review. Benchtop tools are very useful in shops with limited space like garages and basements. So it’s the perfect size to kick off our month of drill press reviews.

This drill press takes about 30 minutes to assemble following well written, easy to follow directions (not always easy to find these days!!). All of the materials are heavy duty and well built.

Power & Variable Speed

Model 3320-01 comes with a decent 3.2 amp motor that provides nice power for all the drilling tasks that we attempted. The key to the power is the adjustable speed pulley system located above the motor.

By adjusting the location of the drive belt on the pulleys you can set the drill press to five different speeds.

- 570 RPM

- 900 RPM

- 1390 RPM

- 2050 RPM

- 3050 RPM

Adjusting the drill bit speed is essential for drilling with different bits, bit sizes and materials. You can find a very useful drill speed chart here that gives some great information on the correct speed of drilling based on bit type, size and material.

This drill press uses a manual belt adjustment for changing speeds. Basically that means loosening some belt tension knobs on either side of the housing, manually sliding the motor forward, adjusting the belt and then reversing the steps. If you don’t change speeds very often this isn’t a big deal. If you need to change speeds often you might want to select a drill press with a tension lever.

Adjustable Work Surface/Table

The SKIL Drill Press offers an adjustable work surface built from a machined cast iron plate that easily moves up and down with a crank handle located on the support column. In addition the table can be tilted left or right up to 45 degrees for angled holes (as shown in the adjacent photo).

The work surface table offers slots so that you can use a variety of fences and clamps that use slots. If I had one complaint it would be the small size of the work surface and the lack of a slot for a sacrificial wood block for the drill bits to bottom out on.

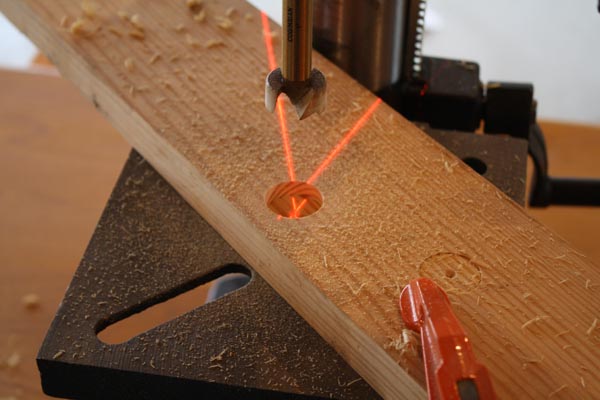

LaserX2™ 2 Beam Laser System

The 3320-01 comes with a laser beam system that helps align drill bits on the work piece. As you can see in the photo above the LaserX2™ 2 Beam Laser System projects two laser lines on the work piece. Once you’ve aligned the lasers it really makes lining up large bits (like the Forstner bit shown) much easier and accurate. Aligning and adjusting the lasers is really easy to do. I did find that you need to adjust the laser each time you move the work surface if you want to maintain a really accurate position.

Safety Features

Safety Features

The SKIL drill press comes with a nice large front mounted paddle on/off switch with a built-in safety key. I like both of these features especially for a benchtop drill like this where kids might have easy access to it. As you can see in the photo the safety key pops out of the on/off switch so you can disable the switch when you’re not using it.

I also like having a big paddle on/off switch located on the front of power tools like this one. It makes it very easy to see and recognize in the event of an accident.

Overall Impression

The SKIL 10″ Benchtop Drill Press is built with quality materials similar to much larger more expensive drill presses. If you’ve spent much time working with drill presses you’d swear they were all built by the same person as the designs are so similar.

I found this model to be a very good choice for someone with limited space and a limited budget. It offers most of the standard features that you’d want in a drill press including: adjustable speeds, adjustable depth control, laser sights, adjustable work surface and a large 1/2″ chuck to accept most standard drill bits.

Priced at just $119.00 at Lowe’s this is a great value. I did read some negative reviews on their site about some wobbly spindles but I couldn’t reproduce that issue so I think those were isolated issues. All and all I’d recommend this benchtop unit to anyone with limited space and a limited budget.

About the author

30 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

After reading your article I decided to buy the Skil 3320-01 10-inch Drill Press at Lowe’s for $119. I noticed that Lowe’s sells the model number 3320-01 whereas most other places have model number 3320-02. I couldn’t find information about the differances between the models. They look exactly the same. Unfortunately, assembly stopped at a very early step: “Loosen set screw in column ring and remove the ring”. Well, that column ring just would not budge even after completely removing the set screw. I tried tapping it with a hammer without luck. I’m sure I could have placed the whole assembly into a vise and pounded that ring off but why should I risk damaging a brand new drill press? I tried calling the customer service number but apparently they are not available on weekends. So after some cursing and frustration I have packed it back in the box and will be returning it to Lowe’s for a full refund. I may try again with model number 3320-02. Perhaps some defects have been corrected in the more recent model. I was really looking forward to using the drill press this weekend but I guess my project will just have to wait.

Nick – Sounds like maybe the column tube has a defect that was pinching the collar in place. Good choice bringing it back.

I too was surprised to find the column ring so hard to remove but by using a rubber hammer and working around the column and moving it a little at a time it eventually loosened up and I could proceed with the setup. After removal I noticed that he factory had tightened the set screw down so hard as to burr the column. I assume that is the cause of the difficulty in removing the ring.

That happened to myself as well… I put alittle WD40 on it and tapped down w/ rubber mallet and presto… However,

to your point, the damn thing wouldn’t budge prior to that.

I’ve looked around quite a bit on line, and there’s not many reviews of Skil presses (the 3320-02 is particularly hard to get info on).

You’ve nailed a really solid review here and the photos are a really great addition. Love the crosshair laser!

I can’t get the table to tighten on the column no matter how hard I tighten the lock.

Has anyone else had this problem or is there something wrong with my press?

Is the bolt engaging it’s threads on the opposite side of the collar?

I know this is old, but anyone searching for info. I had this problem first assembling it because it’s the one detail not mentioned in the instructions.

If you look at all the pictures the table lock is always on the left side (if facing the on/off paddle button) The handle must be on the left side, only the right is threaded.

Thanks for posting that, because I was wondering if I was a feeb or if the equipment was defective, but nope, I was just putting it in from the wrong side. >_<

I just finished setting this drill press up in my garage. I know exactly what Rory did. I’m sure he figured it out shortly after submitting his question. Only one side of the locking ring is threaded. Rory must have started the locking lever in on the threaded side and there’s nothing to catch the thread on the other side. Take it out and put it in from the non-threaded side and there you are.

Solved my problem,belated thanks.

Can’t find the height of this drlll anywhere. Basic dimensions sure would be nice…

Bob – I don’t have the test model anymore, but I’d estimate it at around 30 inches tall.

I was thinking about getting one of these and I was wondering about the noise level.

Not overly loud….I’d say it’s similar to most drill presses, if not a bit quieter because of it’s size.

Looking that this press for a starter. It’s needed primarily for making hole cuts using a forstner bit or hole saw. As I understand it using either bit is a matter of RPM and pressure vs. the type of wood. So my question is this… How well will this press hold up for this purpose, is the motor strong/durable enough?

Thanks in advance.

Jim – The more important question really is how often will you use it? Will this be for hobbies? occasional use? or used quite often. I’d say this is a hobbiest type drill press.

Is this drill powerful enough to drill through hard metal? as in knife making. Thanks a lot, great review¡

Sure…..it’s more of a question about whether you have the right drill bit. I will say, if you plan on doing that often, you might want a larger more powerful unit.

i just purchased one for my first drill press..i’ll be damned if i can get the motor to budge, so i can change the belt speed. even the vibration of the machine won’t jar it loose. ( Cause it’s spinning too fast..) i’ve taken a rubber mallet to it, nothing will jar the motor loose. but it jars everything else loose.. handles, the drill press itself on the column.. not sturdy AT ALL.. YET THE MOTOR IS STUCK. i feel like wiley coyote playing with a recoiled catapult, and i’m jumping on the rock.. everything else vibrates loose, except the motor.. any tips..?? anybody else have the same trouble.. suggestions, eh’..??

Cons

Low quality, Not durable

ACME Drill Press.

I realize this is years later, but did you ever find a fix for this? I assembled mine yesterday and today attempted to change the speed. Unfortunately, cannot move the motor any closer to the head to adjust the speed. So, it runs really fast… or I cannot use it at all.

[…] press this would be a great project to justify it’s purchase with your significant other! The Skil benchtop or Ridgid floorstanding press would be an excellent […]

Is there a mortising attachment available ? Is it any good ?

Not that I’m aware of, might be able to use an aftermarket version though.

I’ve only had it a few days now, used it quite a bit for a few projects that had been waiting on the press.

In my experience the laser didn’t need to be adjusted. I haven’t needed to rotate the table at all, which I could see making that necessary, but it’s pretty well lined up to the center point of the chuck.

No matter the depth or table height it’s on the spot. I’ve seen a few complaints the laser wasn’t lined up, though it’s pretty easy to adjust, I haven’t had occasion to. I tested it quite a few times at various points in my use and it’s still spot on.

I just bought one from a friend who barely used it. I notice that the cranking gear mechanism is very sloppy when changing direction from up to down. It takes about 2 turns before the slop is taken up. Is this normal or do I need a replacement gear assembly and if so how can I get one?

Thanks

John

I no longer have that model, but if memory serves me right that sounds familiar. Even some of the higher end ones are like this.

I bought the 3320 Drill press and it works “ok” for a cheap drill press.

Problem occurred when I moved….the “safety key” didn’t make to the new work shop….so I called Skil to order another just to find I would have to order the switch assembly and it is on back order with NO in stock date….no idea when it might be in stock. When to a couple of parts sites online…same thing…out of stock and no idea when they might have one. So now my project is on hold for who knows how long and right now the drill press is looking like a boat anchor. Any suggestions as to how

or where I can it working again?

Is this an appropriate drill for drilling stones?

I just acquired a Skil 3320 drill press and assembly was no problem, but it runs counterclockwise. How do I get to run clockwise?