Best Tape Measure

Best Tape Measure Comparison Testing

Who Makes the Best Tape Measure? Tape measure and hammer brands often cause more debates on the job site than anything else, and I can see why. When you use a tool daily, hourly, or more, you become attached to it. One of the most critical tools required by all construction trades is the tape measure. So, who makes the best tape measure? Pro-grade tape measures must retain their accuracy while enduring the regular abuses, such as drops or bumps, that occur on job sites.

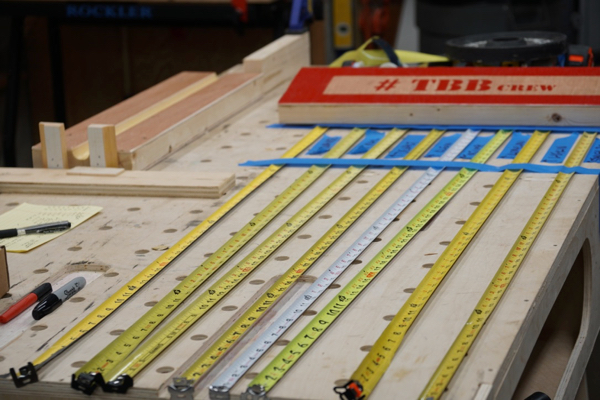

In this Best Tape Measure Head-2-Head, we put several 25’ premium tape measures to the test.

We evaluated 8 different tape measures from 7 different manufacturers, five of which had magnetic tips.

The tape measures:

- Dewalt DWHT 36225

- Klein 86225

- Milwaukee 48-22-7125

- Stanley FMHT 33865

- Stanley Powerlock

- Lufkin L1025MAG

- Tajima G-25BW

Why 25-Foot Tapes?

While there are certainly many other tape measures to choose from, we chose to look at the more popular, pro-grade tape models. We also chose to look at 25-foot length models, as they are the most popular length tape measures sold on the market. We put each tape measure through the following tests:

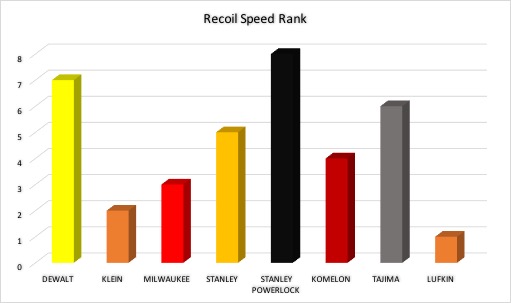

10-Foot and 25-foot Recoil Test

It is never a smart idea to let the tape measure blade whip back into the case– a tape measure isn’t designed to withstand a short, sharp shock over and over. When repeated, full-speed rewinding of the tape measure causes damage to the inner workings, the end hook, and the blade markings.

However, during our testing we did just that! We tested recoil from 10-feet and 25-feet to establish a benchmark speed. We then used our benchmark speed to test the tape after abrasion, debris and drop testing.

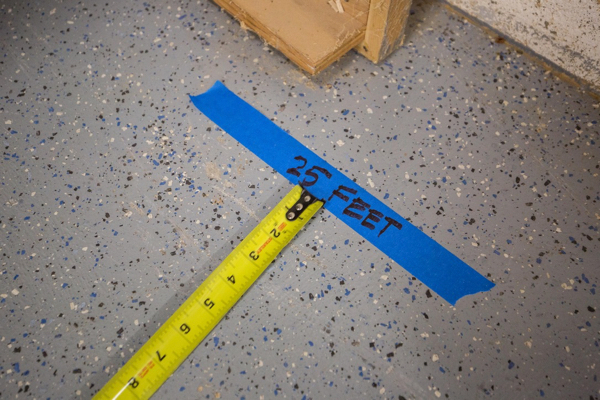

For this test, we measured and marked the distance on our clean shop floor. We pulled all the tapes out to this distance and recorded the recoil five times to determine their baseline average recoil speed.

The Milwaukee tape [below left] bent on the 4th recoil test, one Lufkin tape [below right] broke off on the 3rd recoil test. Several others had their hook movement stretched.

We used several of the same brands during our head-2-head testing. By using several samples of the tapes, we were able to complete and continue testing if a particular tape failed a certain test.

According to our data, Lufkin had the fastest recoil speed, at 1.05 seconds, and that may have been a detriment to it tearing. Klien was second at 1.08 seconds, and Milwaukee was third with a 1.20 second 25-foot recoil.

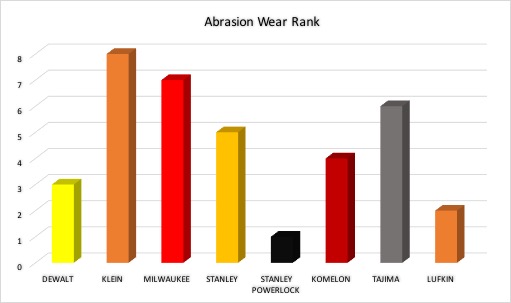

Abrasion Test

Tape measure readability is important; over time, tape markings wear off and make the tape difficult or impossible to read. Furthermore, wear down of the tape coating is the #1 failure of tape measures.

All tape measure manufactures follow the ASTM D 968 and other internationally recognized test standards, the Falling Sand Abrasion Tester. The Falling Sand Abrasion Tester measures the resistance to abrasion of paint, lacquers, and other organic coatings. Abrasion results from abrasive particles falling through a guide tube and impinging the test specimen, until the substrate becomes visible.

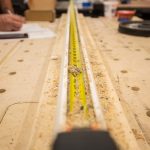

The abrasion jig we used was more aggressive. To simulate and accelerate tape-marking wear, we performed an aggressive tape abrasion test in the shop, through the use of an “tape-pull abrasion jig.” It measured 26” long and had a hollowed-out, concave center bottom. The top of the jig had a 3/8” wide convex pressure-point. Adhesive grit sandpaper was applied to the convex point and wax was applied to the concave side.

The tape measures were placed in the jig, which had a very small gap for it to fit. We placed a 25 lb. weight on top, and then pulled the tape using a slow 1000-count back and forth through the jig. This allowed us to evaluate a 60”span of tape wear. Tape marking wear was then noted and photographed.

The Stanley PowerLock had the least amount of visible wear to its tape. Lufkin came in second place, Dewalt third, and Komelon came in fourth.

NOTE:

Many contractors use the first 6” or less of their tape more than the full 25-foot length. As a result, many tapes wear quicker in these areas.

To combat this, the DEWALT, Stanley FATMAX, and Stanley Powerlock all added a clear thermoplastic “Blade Armor” tape over these high wear areas. DEWALT added 9” of thermoplastic coating, and the STANLEY FATMAX features a Mylar blade coating and 3” of BladeArmor. While the STANLEY Powerlock has a Mylar blade coating.

Milwaukee, however, uses a Nylon extrusion process. This process melts down nylon pellets through proprietary machine, which coats the entire blade. This coating is then baked in a furnace. Komelon also uses a “sprayed on” nylon blade coating process, some like the L1025B that we tested has a matte nylon finish to reduce glare.

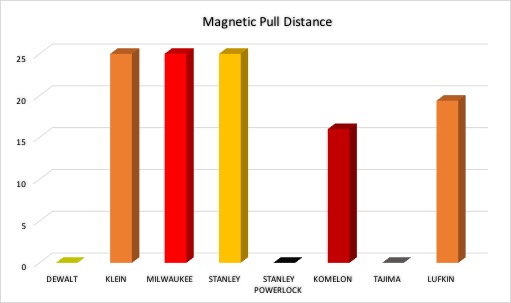

Magnetic Pull Test [If Applicable]

Many contractors use magnetic tapes– from metal stud, to HVAC, and plumbing. Thus, we wanted to glean some insight on who sported the strongest magnet. To test this, we attached each tape’s magnet to 3/8” metal plate and pulled. In our opinion, all of tapes should be able to extend FULL 25-foot length, and while some did, others didn’t.

Three tapes were able to extend full-length:

- Klein

- Milwaukee

- Stanley FATMAX

The Lufkin made it to 19’4” while the Komelon made it to 16-feet. I’ll be completely honest with you, we all have favorites, mine was the Stanley PowerLock, but I was falling in love with this Komelon tape at this point in the testing.

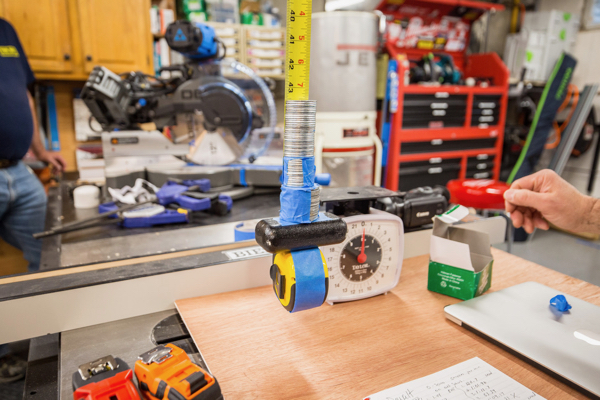

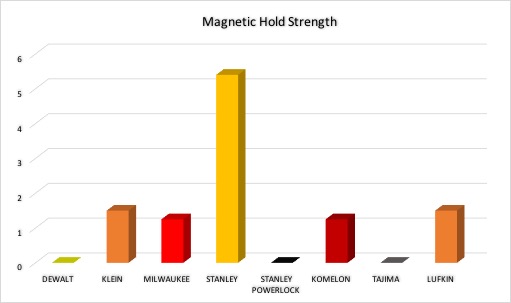

Magnetic Weight Test

On this test, we wanted to eliminate the risk of user twist or torque. We attached the tape measures that had magnets to bottom of ceiling non-galvanized joist hanger, extended the tape, applied the tape measure lock, and then applied blue tape to the tape and body to reinforce the lock. We used the blue tape because we found that many of the tape measure locks failed, before the magnet did.

For this test we placed pre-measured weights on top of the tap measure until the magnet failed. This test gave us an indication of how strong the magnet was.

The Stanley FATMAX blew the doors off the competition with a 5.5 lb magnet strength. Second place was Milwaukee at 2.25 lbs. Followed by Klein, Komelon and Lufkin at 1.5 lbs or less.

Debris Testing

Trades that work in extremely dusty environments will tell you that it doesn’t take long for the recoil on the tape to get sluggish or completely stop. Water or dirt that gets on the blade of a tape measure can work its way into the mechanism and cause slug, rust or jamb up the winding.

For this test we designed a torturous debris chamber recoil test. We modified a 3” pvc pipe to hold a medley of drywall dust, saw dust and sand.

Each tapes pulled out to 25′ and allowed it to recoil slowly. We repeated this sequence 4 times. This test proved too much for most of the tapes. Many of them would not retract and close less than 6-inches. We had to pull the tapes in and out to get them to close completely.

Once closed, we tested their recoil twice, from 25-feet while measuring for time. The BEST tape measure in this torturous test was the Stanley FATMAX which stopped at 9-feet on the first recoil test and then completed the recoil test at 1.9 seconds.

Followed by Lufkin which recoiled to 10’10” on the first test, and 6-inches on the second test. The Stanley PowerLock, in third place, stopped at 10’-4” inches on it’s first test, and only recoiled 25-inches (total) on its second test. The DEWALT, Klein and Milwaukee all recoiled to 14.5 inches or greater and failed to recoil at all, on the second recoil test.

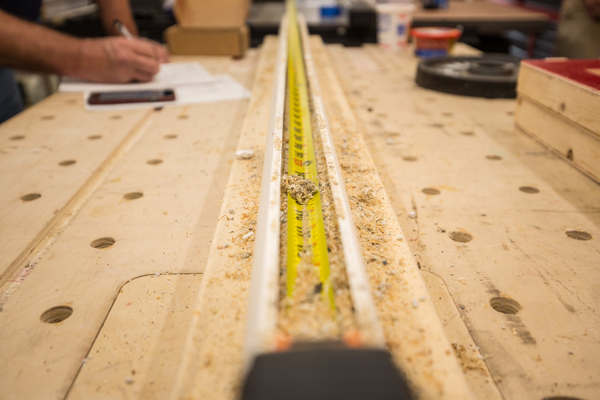

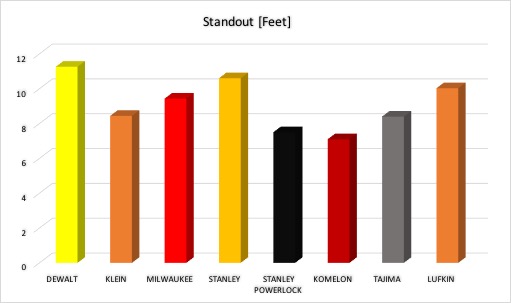

Tape Measure Standout

Stand out is big to some guys, because a long reaching tape is useful when measuring alone. Stand out basically refers to how straight you can extend your tape without it bending or losing is rigidity.

We made a jig with a 15-degree angle and tested each tape three times for an average stand out measurement. The DEWALT stood out here, pun intended, with the longest standout.

Standout Results

- DEWALT 11’3″

- Stanley FAXMAX at 10’6″

- Lufkin at 10’0″.

Hook Movement

Have you ever wondered why the hook is loose?

All of our pro followers already know why the hook at the end of a tape measure is loose. But for any novices, the looseness is very intentional and plays a key role in using the tape for both inside and outside measurements.

When you butt the end of the tape against a surface for an inside measurement, the tip is compressed against the end of the tape by the width of that hook. (Spoiler alert – the first inch of the tape is short by the thickness of a hook.) When you go to take the outside measurement and hook it over the edge of whatever you are measuring, the hook moves away from the tape by the width of the hook.

We examined just how accurately the manufacturers built their tapes for this inside/outside hook movement. And we wanted to see how the hooks on the tapes stood up to after our retraction test. The results varied.

Out of the box, the Lufkin was most accurate with the hook thickness of .045” equal to the hook movement of .045” Most other tapes had a difference of .01” in these measurements. The Milwaukee tape had the greatest difference at .022”

After the retraction tests, we measured which tapes held their tolerances and which showed a marked difference after that test.Our theory was that the rapid 25-foot retractions would eventually loosen the tape hook, distorting its tolerance. We were right.

In this comparison, both Stanley tapes performed well. The Stanley PowerLock reading was identical and the FatMax varied by only .01”. Milwaukee also matched the FatMax performance of .01”. The Lufkin tape showed the largest difference, increasing by .045”, almost a full hook thickness.

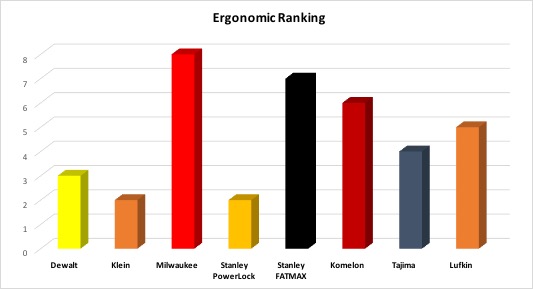

Ergonomics

Ergonomics is about designing for the end user. Defined as the science of fitting a workplace to the user’s needs, ergonomics aims to increase efficiency and productivity and reduce discomfort. For ergonomics we look at:

- Grip

- Weight

- Lock

- Belt Clip

- Ability to sit flat on a surface

- Hook

- Overall Construction

The best tape measure in the ergonomic category was the Milwaukee. The crew liked the detent on the back of the body, and finger brake on the bottom. The Milwaukee body has plenty of rubber over-mold on top and base. It was the MOST Stable of all the tape measures, when placed onto a flat surface. The extremely durable hook has solid rivets, a super strong magnet, a screw- nail slot with 2 upper tabs.

The Milwaukee tape measure features a unique belt clip constructed out of wire bale instead of a flat piece of metal. The clip is specifically designed to reduce wear and tear to pants and tool bags.

The crew noted that this belt clip was difficult to apply to a pant pocket one-handed, but once applied it does a phenomenal job holding the tape in place.

The Stanley FATMAX was a close second for ergonomics. It has a rubber over-mold on top back and bottom, a strong, secure, positive clicking tape-lock that can resist 4 lbs.

The crew liked the belt hook, and low profile magnetic hook with its screw – nail slot on lower tab and two upper tabs extensions. Third place went to Komelon which is a very comfortable tape to use, smooth recoil, and one of my favorites.

Readability

Readability and durability are two words that stick when I think of tape measures. Three tapes tied for best tape measure readability.

- Milwaukee

- Komelon

- Lufkin

The Milwaukee tape features a 1/16th yellow scale and is 2-sided. On the back end of the tape the numbers allow you to read upside-down. Additionally, there is a small 12″ long architectural scale for plan measuring featuring a 1/8 and 1/4 inch scale. This scale starts on the back of the tape at 10 inches and runs to 22 inches.

The Komelon,features a 1/16 scale, is easy to read with its high-vis yellow on top, white tape on back side [2-sided] tape. The crew felt that the Komelon may be the BEST of the tapes to read, based on the tape color! One thing the crew noted was that after the 12-inch markings, the tape markings get a bit busy to read. [For example; 13-inches is listed at 13 and also 1F 1.] We felt the this marking pattern made the tape very busy and was unnecessary.

The Lufkin Yellow tape, is also 2-sided, with a 1/16 scale. The markings are longer on this tape, and are labeled similar to the Komelon after 12-inches.

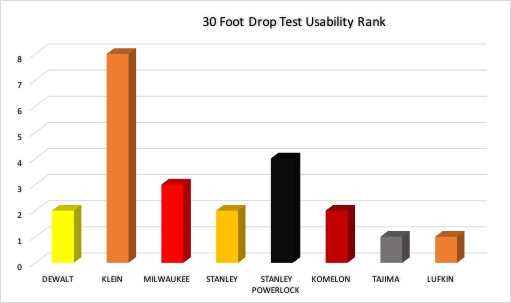

Drop Testing from 15-feet and 30-feet

We dropped the tapes onto pavement, once at 15-feet, and a second time at 30-feet. After both drops, we recorded and noted each tapes’ condition. We set up a personnel lift to do our drop testing.

Almost all of the tapes survived our 15-foot drop test. The Klein tape measure sustained the most damage. The Klein’s hook bent and the case opened. While it’s possible that the Klien hit the ground perfectly to dent the hook, we feel that the case should not have opened up from 15-feet. Also damaged was Stanley FAXMAX, DEWALT, Milwaukee and Komelon with slight case or hook damage. The Tajima and Lufkin came in first place on the 15-foot drop test. Both tapes worked perfectly and had zero visible damage.

On the 30-foot drop test the two most durable tape measures after drop testing were the Dewalt and the Stanley FATMAX, both sustained the least damage and were still usable after the test. Lufkin and Tajima came in tied for second place with slightly more damage but less than the rest of the pack. The Klein came in last, due to its case braking open on impact.

Price

- Dewalt DWHT 36225 – $29.97

- Klein – Upper #86225 – $24.66

- Milwaukee #48-22-7125 – $23.96

- Stanley FMHT 33865 – $ 22.98

- Stanley Powerlock – $ 11.00

- Lufkin L1025MAG – $ 16.80

- Tajima G-25BW – $ 20.91

- Komelon 73425 – $ 11.05

BEST Tape Measure Overall

The BEST tape measure overall was the Stanley FATMAX. The FATMAX had the highest score in magnetic hold, debris testing, drop testing, hook durability and blade thickness. It placed second in four other categories, securing the #1 slot in our testing.

One of our crew referred to it as a “brick-shit -house” of a tape measure.

While I’m sure Stanley marketing team won’t use that description, it’s certainly a durable, robust and well-made tape measure, designed for harsh job site conditions.

Buy Now From Our Sponsored Retailers

Scoring only one-point less than the FATMAX, in a super close race, for the best tape measure was neither a crew favorite, nor on anyone’s radar, during our tape measure testing.

This dark horse sneaked by the competition and took the #1 slot three times in several testing categories, and scored #2 three times and #3 six times.

The second best tape measure is the Lufkin.

After the testing it was apparent to me that these devices need proper care in order to provide you with accurate, reliable measurements. Caring for your tape measure is easy, here are a few steps for properly maintaining your tape measure.

| Best Tape Measure | Dewalt | Klein | Milwaukee | Komelon | Stanley PowerLock | Tajima | Lufkin | Stanley Fat Max |

| Ergonomics | 6 | 7 | 1 | 3 | 7 | 5 | 4 | 2 |

| 25 Foot Recoil | 7 | 2 | 3 | 4 | 8 | 6 | 1 | 5 |

| Abrasion | 3 | 8 | 7 | 4 | 1 | 6 | 2 | 5 |

| Magnetic Pull Test | 0 | 2 | 2 | 4 | 0 | 0 | 2 | 2 |

| Magnetic Hold | 3 | 3 | 2 | 5 | 3 | 3 | 3 | 1 |

| Debris Test | 6 | 8 | 7 | 4 | 3 | 5 | 2 | 1 |

| Standout | 1 | 5 | 4 | 8 | 7 | 6 | 3 | 2 |

| Readability | 2 | 3 | 1 | 1 | 2 | 2 | 1 | 2 |

| Drop Testing | 2 | 4 | 3 | 2 | 4 | 1 | 1 | 2 |

| Drop Testing | 1 | 8 | 5 | 5 | 5 | 3 | 3 | 1 |

| Construction | 1 | 3 | 2 | 1 | 3 | 2 | 3 | 2 |

| Hook Durability | 3 | 2 | 1 | 1 | 1 | 2 | 3 | 1 |

| Blade Thickness | 2 | 3 | 1 | 3 | 3 | 1 | 2 | 1 |

| Price | 8 | 7 | 6 | 2 | 1 | 4 | 3 | 5 |

| TOTAL SCORE | 45 | 65 | 45 | 47 | 48 | 46 | 33 | 32 |

Buy Now From Our Sponsored Retailers

Best Tape Measure Video Review

About the author

65 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

“Short, sharp, shock” Thank you, Roger the Hat

Did you test for measurement accuracy across different brands?

We did – zero issues. In hindsight we should have discussed that. Thanks for the comment!

I find it very hard to believe this.. at my job we primarily used Stanley measures, Lufkin, and Starrett .

Whenever a new guy came in with their favorite, we’d explain the accuracy issues, and would compare them on the spot, with a shear blade gu

age. In doing that, you immediately see discrepancies, often within EVERY 4 INCHES, the tape accuracies would drift in and out, sometimes as far as a half inch, which would “recover” over the next 4 to 8 inches. Point is.. only the Stanley tapes.. (all 5) had consistent drift, closest to the Starrett metal ruler embedded in the shear . With product having typically 4 workstations, it was useful to know that the shearing breaking, welding, assembly stations, it was going to be measured semi consistently.

What do you not believe? Our winner? Can you be more specific?

I am in the fire sprinkler business +50 years, surveying various types of buildings, tanks & structures & prefer the Stanley 25′ tape over all other tapes.

I would love to see this test on a stabilla tape measure. Yes they do exist.

Next time, please test lockout, some trades use tape measure as an adjustable stand, for example when soldering verticle piping, or trying to hold light objects up at perfect height.

One item I didn’t see on the test is reading an inside measurement by locking the blade lock, withdrawing the tape and reading it, then adding 3″. I use that feature enough to where I wouldn’t consider a round-box tape measure, so all I ever buy for my construction outfit and my students is a sure-box chrome Stanley

Hi Bob – we did check the hook in that fashion for accuracy

He’s talking about using the length of the body of the tape measure.

What about resistance to water(rusting and seizing) I’ve had two fat max that got minimally wet and refused to work the next day so I’ve switched to Milwaukee (gen 3) and no problems so far.

We did – zero issues. In hindsight we should have discussed that. Thanks for the comment!Long term – no we didn’t

I’m unclear on how drop testing is ranked. Is a higher score better or worse? The numeric scores don’t seem to agree with the written description.

Hi Jeff- the lower graphs did better. Ill do the graphs differently next time – good feedback

not my many years of experience with tape measures at all. I haven’t tried them all but dewalt and stanley,fatmax are way overrated. Fatmax extends well and that is all. in a few months it falls apart and is very expensive. the best tape measures by far are malwalkie. they are inexpensive, easily readable and are very durible.

It’s certainly a GREAT tape and is now improved. Gen 3 is out

Thank you for this article. As a tradesmen of more than 30 years I have been through my share of tapes measures. Regardless of how many tape measures I have, I often find myself buying another one if it’s a good deal. I have always liked Stanley tape measures but recently purchased a Milwaukee with the magnetic hook. The majority of my work has been finish carpentry and I liked everything about the Milwaukee except the magnetic hook. It made it impossible to read the first inch of the tape. I replaced that Milwaukee tape with there non magnetic hook and the first inch is good to read. I find it surprising how vast a difference there is in the pricing of the tapes. I guesss it proves the saying if you want something that works and is going to last you are going to pay more for it. One last thought, I find myself checking where the product was made before I purchase it. Almost anything with a built or made in the USA is good with me. Thanks again for suck a detailed article.

Jim – thanks for commenting. Hope you meant Such and NOT suck 😉 Just kidding

Any tests for accuracy?

Hi Steve, we did that when checking hook

As a Woodsmith I have found that the Craftsman sidewinder tape measure is a godsend to use. Before I would try to make a mark on a board and then the tape measure would fall over, but not with this one. Also, why did you leave out the Baileigh Job site table saw, I’ve been waiting to hear from an pro what they think of their saws.

How about accuracy? Recently, we laid a few different tapes, side by side and noticed a difference. Theses tapes are, I believe, all Accuracy Class II. There are a few Accuracy Class I tapes out there…

Thanks for your comment. I had not come across the distinction before. The page below has a chart showing the accumulation of error in an EC Class I versus and EC Class II tape measure.

From https://www.thetapestore.co.uk/knowledgebase/Articles/The_Advantages_of_a_Class_1_Tape_Measure.html

“The Advantages of a Class 1 Tape Measure

As an example let’s compare a class I with a class II tape. EU guidelines state a class I tape up to 2m in length must be accurate to within a margin of 0.3mm. Under the same guidelines a class II tape of the same length should be accurate to within 0.7mm.”

At 8 meters, the EC Class I tape is allowed to have an error of ± 0.9 mm, while the EC Class II tape is allowed an error of ± 1.9 mm.

Accuracy was great out of box, no story there – but in retrospect we should have reported it. Great feedback thanks

It was interesting until I got near the end and saw the prices. I have a tape in all the work stations in my shop where I might need one. These are the Harbor Freight tapes that are often free when You are purchasing something else. I lose them before they ever wear out and since I have seven tapes in my shop one at the rip saw one at the table saw one at the radial saw one at the chop saw one on my bench and one at the drill press. They all seem to work fine and if one of them didn’t I have a few more in a drawer. I can replace them for next to nothing and I will

I’d be curious to check the accuracy of al those tapes to see if their the same

I’m going out on a limb and say they probably aren’t.

Had to replace a tape a couple of months ago and bought a stanley powerlock. Compared to my previous old powerlock, the blade itself was much thinner (at least 20% thinner than my old model when I miced it), had a stand out of just over 6 feet and curled whenever you were not holding it horizontally. Whatever stanley did with their most recent manufacturing process, it sucked. Threw it in the garbage and bought a milwaukee. Stand out on mine is at least 9 foot plus and the blade is significantly thicker. Stanley tools seem to have declined significantly in quality.

I’ll 2nd the motion. I recently sold 5 Stanley Leverlock tapes (8′, 2-16′, 2-25′)at a garage sale because after a few months of little use, the print on each of them began wearing off, the the leverlocks began to fail and the recoil hardly worked. I bought 2 more 25 footers at a grand opening of a hardware store and less than 2 months later, the Leverlocks failed completely, the recoil doesn’t work unless the tape is forced in and the tape measure is pointed up so that gravity wiil assist the recoil, the hooks constantly slip off the item being measured. Finally, the hooks are to short and will not catch on a board by just using one hand and pulling the tape measure. I also bought a 25′ magnetic leverlock and a month later the leverlock failed. Stanley quality is, IMHO, non existant. A cheap Menards brand, Performax, is better quality; not the best quality but better than Stanley.

Nice test !

I wonder if any of those brands ever starts to produce a “lefty” version of tape ? So when I measure with the tape in my left and pen in my right hand, I will not have to read the numbers upside down. I would be ready to pay a little extra for that feature !

Keson and Lufkin make some tapes with “vertical” markings that read well from either side.

You know its funny that all the tapes you checked out are all read upside down numbers. These taps are make to hold in the left hand and hook on the right hand side which the numbers will be up side down and hard to mark. Why are not the tapes made to have the numbers right side up?

Please respond:

Thank you:

Louis Castellucci

lou04@ca.rr.com

In the meantime, I did some research.

(Coming from metric Europe, it is even more complex… 🙂

Fastcap makes some nice tapes (check ProCarpenter reverse) – including one you can write on – ingenious for layouts ! But only standard and right handed 🙁

I found company in UK, which makes a “ViceVersa” tape – dual reading & both sides – will go with this one, as shipping costs do not kill it for me.

@Louis:

I have 2 theories why this is the way it is:

1)In math, 0 is always on the left side, so tapes comply.

2)This is a revenge of all left handed people, so we know how they feel most of their lives. In that case, fair enough! 🙂

Somewhere out there is a post from a pro. carpenter, who says, that switching to this “lefty” tape has significantly decreased the number of errors he makes…

When measuring, holding the tap in the left hand and hooking the end at the right end of the tape, why are the numbers upside down. As fare as I can see, all the manufactures make their taps the same way. When marking a measurement with the number up side down it is not hard to make an error in marking. Can someone explain why.

Thanks:

Lou:

It’s because we read (words, letters, numbers, etc.) left to right. That’s why a tape reads right side up when pulling left to right and upside down (and backwards) when pulling right to left.

Excellent test guys, I have always been a Stanley fan, I now have the Fat Max auto lock which I can’t recommend enough. The auto lock feature that you can turn on or off is an excellent option if you are working on your own, along with the 3.3metre stand out. Also the magnet is detachable, another plus, along with the spare attachable wide blade for hooking underneath objects. All in all I don’t think it can be beat at the moment in terms of options.

Ever since the Fat Max came out 18 or so years ago I have enjoyed the wider blades resistance to turning over in windy conditions. However, it seems as tho the same Fat Max as manufactured today doesnt have that same quality as those originals. And for the last 6-7 years, every Fat Max I have purchased has trouble winding back in from about 4 feet and less… what used to be a one handed op when marking multiple boards to cut now requires both hands to bring the blade back in. Very frusteating.

I would hazard a guess that not too many products mass produced today have the same quality from 20 years ago. That’s why some of us old timers are still using tools my dad bought. It’s been a throw away world now for awhile. They engineer it that way.

I’m really surprised no one complained that the Fatmax hook goes flush with the body if you give it and vertical pressure. This makes it tough to grab onto the hook. That’s the reason I returned mine.

That’s only for the non-magnet version. They made one body for both the magnet and non-magnet options. If you don’t get the magnet then there’s too much room and the hook can move up too much. That’s why I didn’t get the FatMax this time around, I couldn’t grab the hook easily.

The brand I use and love is the komelon. For the price I paid for mine 10.99 it is well worth it. I could spend 20-30 dollars on a fat max but I can buy 2 or 3 komelons for the same price.

Who cares about abrasion or debris tests. I want a tape measure that I can measure the ceiling for crown molding that doesn’t fold over at 10feet. Some of these tests are useless to the every day use of tapes.

Matt, the abrading of the markings is the #1 reason for failure of tape measures. Maybe not in your area of carpentry but in the industry as a whole. We also did a stand out test, indoors with no wind, which is what you would encounter measuring crown. Unfortunately not many can surpass the 10′ mark but the results are posted above.

For your scenario a laser distance measure would work quite well. In fact, Stan reviewed the Bosch GLM 50 C recently that has the functionality of linking to your smart device and laying an easy 2D drawing based on the measurements. That would be perfect for crown. The review can be found here. https://www.toolboxbuzz.com/measuring-layout/bosch-professional-glm-50-c-laser-measure/

I have worked outside in all weather conditions building Morton Buildings for 14 years. I’ve tried several tape measures over the years and the FatMax is absolutely the best. Great test!

I wished they would have tested the hook to see how well it held when pulling out the tape and how well it would grab the edge of a board so it could be done with one hand. Many times, my left hand was holding something when I needed to take a measurement and couldn’t “hook” the hook.

Hi Ken, we spent significant tie evaluating the hooks. We may not have articulated all of it but the results are in the ranking.

I Prefer KDS brand over stanley.

It is a Japanese brand

CAn you do a review for KDS brand?

What about the new Komelon Contractor tape with 1-1/4″ blade?

I owned a tape measure that had the inside measures marked on the back side of the tape. That was an indispensible feature for me. Why all these makers don’t offer that is beyond me. That would double the usefulness of a tape measure.

I know it took alot of hard work and diligence but could you and your crew do a 2020 update for the new models? Your results are the only tool reviews i trust on the web.

Clark – I’m sure we will one day…not soon likely as we have lots of other products to compare.

Thanks Clark

The information is all well and good but to me the most important thing and the one thing they didn’t test was accuracy. If it isn’t accurate the rest doesn’t mean much to me.

Bill – I’m interested in what you’d like to test for accuracy? The bottom line is this, it’s a tape measure, not a machine rule or high precision measuring rule. I’ve never found myself with a tape measure that I felt wasn’t accurate enough for what I use a tape for. When I’m in the shop, I use more accurate machine rules when tight tolerances matter.

That may be you.

But a whole point of a measuring tool is to – well – MEASURE.

A review of a measuring tool WITHOUT an accuracy/calibration report before/after every test – specially the speed tests where a GOOD tape would break instead of bending etc.

As for accuracy. There are tapes our there which are inaccurate to the point if >1 mm/m which is HUGE and makes them unusable for a, lot of things.

But the main thing is that a more robust measure will invariably be less accurate as the more a “bendy” a material is the less accurate it is by definition. So without accuracy rating associated with each of your tests they are basically useless.

Excellent point thanks for making it. All of these tapes measured accurately our of the box. there were no issues but we should have made a bigger deal of that.

On the flip side, for a lot of people, accuracy is highly over-rated. The reason being that if you measure and cut with the same tape, accuracy has no bearing whatsoever on the outcome. Accurate to the thickness of the pencil mark is all anyone will typically get with even the most accurate tape measure. This is why I do trim work with a mechanical pencil rather than a “carpenters pencil”. I do my framing layouts with traditional #2 pencils but still keep the tips very fine for the same reason. I know it’ll vary by trade, some guys are “calling out” measurements and those tradesman would technically want to “synchronize their tapes” (like sychronizing watches) at the start of each day if they are aspiring to a level of accuracy beyond what any of these tapes offers. I rarely even try to measure closer than a 16th and a bent tip can easily lead to an innacuracy far greather than that.

[…] another sweetheart of a deal from Home Depot. This time it’s 2 for 1 on the perennial best tape measure. Just $20 is all you need for this one. At this price, buy one for yourself and one for your loved […]

A huge issue for me is the ability for a tape measure to ‘stay’ where it’s hooked. I’ve tried several brands and everyone slips off the edge of a wall or cabinet, square post, or the like. That is frustrating. Perhaps this occurs because the manufacturer designs the tape measure to be rigid enough to extend as far as possible. Thus, when the tape measure is hooked on the edge of a wall, cabinet, or other vertical objects, as soon as the tape measuring case is moved towards the object being measured, the rigid blade forces the hook off.

One possible remedy might be to add small prick points to both sides of the hook. Both sides must be done because when making an inside measurement, the clip slides along the surface.

Im waiting for the digital readout tapes to be invented like you see on digital calipers. Maybe incorporating a last measurement recall button or the ability to add multiple measurements together for a total measurement. Basically a laser/tape for the price of a wooden ruler. Or maybe a blank tape you can mark crows feet onto with a button. Also, a glow in the dark tape for crawl spaces! How about a gps tape that can read your measurement by satellite like some speedometers do now. I should measure my blood sugar soon =)

How about the “Hook” test of the “Hook”. By that I mean, how well does the hook grab and hold. I’ve owned several brands over the years and the older Stanley tape measures would hold just fine. Now, it seems that all manufacturers coat the hook with silicone just to see if they can win the race for slipping off an object the fastest. I’ve even had some tape measures slip off the end edge of a board laying flat

What good is a tape measure if it can’t stay hooked? It makes all the testing you’ve done worthless. After all, isn’t that what the hook is for; to hook and stay where it was placed?. Tape measures that cannot hold to the side edge of a stud long enough to pull it out the length of the tape are simply junk. That’s how I view the #1 priority of any tape measure.

Thank you!

Ken

Lufkin Shockforce. I’ve got the NiteEye version(green on matt black) and the hook is coated in diamond powder to prevent slipping, works a treat.

I’ll check it out.

Thank you,

Ken

Wow. An objective, excellent and thorough test—Thank you!