Best SDS Rotary Hammer Drill – Head to Head Testing

1-9/16″ SDS Rotary Hammer Drill Head to Head

SDS Rotary Hammer Drills are no small investment. Whether this tool is your workhorse in a commercial setting or your life-saver in the residential setting we here at Tool Box Buzz want you to make the best choice for you and your needs on the job-site and help you choose the best SDS Rotary Hammer Drill for your needs!

1-9/16″ SDS or Special Direct System Rotary Hammer Drills are a definite nice to have for professional remodelers whether for demolition, framing applications, or basement renovations. These heavy duty tools can make quick work of concrete demolition, speed up your foundation work, and be a life saver when working in a basement and need to effectively work with concrete. I’m an avid believer in the right tool makes a job faster, easier, and safer so the investment in a heavy duty SDS Rotary Hammer Drill is a solid decision for your business.

For professionals who almost solely work with concrete, drilling holes in commercial concrete structures, the 1-9/16″ SDS Rotary Hammer IS their job. So with each seemingly small advance in SDS Hammer Drill technology the lives of the men and women behind those drills improve dramatically. That’s why we thought it was so important to take a look at the current 1-9/16″ SDS Rotary Hammer Drills on the market and give our readers our professional opinion on their performance to ensure you are making a truly informed decision if and when you decide to purchase one of these tools.

This Head to Head featured all the big names in the Rotary Hammer market, let’s take a look at each make and model evaluated for our Best SDS Rotary Hammer Drill – Head to Head Testing:

Bosch 1-9/16″ SDS-Max Combination Hammer [RH540M] Average Price $420.00

DEWALT 45mm SDS-Max Combination Hammer [D25603K] Average Price $590.00

Hilti 1-9/16″ TE-60-ATC-AVR Combihammer [TE-60-ATC-AVR] Average Price $1,500.00

Makita 1-9/16″ AVT Rotary Hammer [HR4013C] Average Price $590.00

Milwaukee SDS Max Rotary Hammer [5317-21] Average Price $400.00

For more detailed Specifications & Features on each model see listings below photo gallery at the end of this article [“Average Price” above based on review of several major online retailers]

For this Head to Head we appropriately traveled to the “Granite State” to a quarry where we had five concrete slabs awaiting the impact energy and power of these SDS Rotary Hammer Drills. We put these tools up against these slabs testing the demolition capabilities and drilling speed. With hours of chipping, drilling, and hammering we evaluated the comfort, ease of use, vibration, power, speed, and safety features of these tools. Additionally we reviewed complimentary HEPA rated vacuums and their integrated dust control systems for applicable models.

Our team of professional contractors have all weighed in to help us drill down on the best in class SDS Rotary Hammers in the following categories. Let’s see who came out on top.

Case, Kit, and Dust Control Accessories Winner – Hilti TE-60-ATC-AVR

Tool storage is a constant battle in this industry, balancing organization and efficiency against being prepared for any and all scenarios can be tough to accomplish. So it’s a huge plus when the company provides a well put together kit that organizes components and accessories so you don’t have to.

This was a close call between Hilti, DEWALT, and Makita all delivering comprehensive kits and well thought out organization. We loved Makita’s integrated diagrams in their cases to give you an easily accessible quick reference for the tool and how the dust extraction components are intended to be used. DEWALT featured an ingenious dust extraction system with their kit that left a lasting impression on us, which we’ll discuss later.

And finally Hilti who eked out as the winner in this category delivered a high quality and expertly executed kit with all high quality components neatly and efficiently packaged for operator convenience.

Bit Change Winner – All Way Tie

The Special Direct System developed by Bosch in 1975 revolutionized hammer drills allowing a cylindrical shank fit into the chuck with indentations that lock the bit into place yet allows the bit to move up and down a short distance. Therefore you can expect this technology and the accompanying chucks to be standard across the board, hence the all way tie.

Although the one and only discriminator we found was that the Bosch RH540M did not feature a quick change chuck, meaning it was the only model that required you to pull the chuck back to insert the bit, where all other models would accept the bit without moving the chuck and only required pulling back the shroud when removing bits.

Ease of Use and Operating Features Winner – Makita HR4013C

The Ease of Use Category despite being inherently subjective in nature as there is little to no quantitative comparisons between models is continuously an important category for us to note in our head to heads. First and foremost we have enough operators in most tests that we get a wide perspective of opinions.

Also, this category often is a bellwether for the overall winner, which is determined only after category winners, quantitative data, and model specification information is taken into account. So needless to say the “feel” of a tool is a valuable factor in our tests and the opinions you hear are from professional tradesmen and contractors. As we like to say “trust the pros” and in this category we KNOW we got it right.

Makita’s HR4013C hands down continuously garnered quotes from our team like “smooth”, “impressive”, and “that’s awesome”. Whether it’s the additional chipping D handle attachment, lighted lock on button for hammer only use, or just the incredible anti-vibration technology integrated in the tool this model was a stand out in every category. It was easy to use and included all the bells and whistles you’d want in a SDS Rotary Hammer.

Hilti’s TE-60-ATC-AVR was a close second as it is an amazing tool with power, speed, and high end operating features similar to the Makita model. The anti-vibration technology is also quite advanced and the Hilti also performed well in all categories of our evaluation, but consistently Makita was just a bit better in most categories and when you compare the price tag of the Hilti to the rest of the field the Hilti just looks less attractive.

Ergonomics Winner – DEWALT D25603K

DEWALT’s D25603K impressed us with it’s large D handle, solid shock absorption technology, and an innovative variable position auxiliary handle which allows an operator to comfortable stand more erect when working on horizontal surfaces, especially with big bits. These tools can be hard enough on your body without the added discomfort of bending over the drill during work.

Makita’s HR4013C was a close second with the addition of the removable auxiliary D handle for chipping and demolition applications, which, despite being very difficult to put on and remove, allowed users to customize the grip of the tool to maximize comfort during those stressful tasks. Additionally, we have to mention Hilti and the TE-60-ATC-AVR’s ability to comfortably negate the powerful impact energy of the tool allowing the user to bore through the work with very little stress on the body, but we’ll discuss that in detail further in the article.

Chipping Winner – Makita HR4013C

Using a heavy duty demolition tool like a large bit rotary hammer can be very tough on your body. Between the repetitive action, heavy tool, and the irregular and always changing work surface a task like chipping is a great test of how well a tool performs. Furthermore how the operator feels during the work and after the work can be a huge indicator of whether a tool does the works for you or a tool you have to work. Given this concept we think the order of the best in class for this category is on point.

The Makita HR4013C definitely does the work for you, powerful and comfortable this tool matches its performance with Anti-Vibe Technology that prolongs the stamina of the operator and can help mitigate injury from long term exposure to vibration. The Makita also features a unique, detachable, D-grip auxiliary handle. This flexibility allows the user to zero in on a the most comfortable position for the task. Ultimately the Makita HR4013C delivers features that make you safer, faster, and more productive.

The Hilti TE-60-ATC-AVR is a close second here with an unmatched power that you can see but hardly feel. During our chipping test, operators were able to bare down on the tool and watch the concrete flake away while that additional impact energy is never felt by the user. Many of our evaluators mistook this for “feeling underpowered”, including myself, but the more you used the tool the more it became evident that it delivers serious power, and is easy on your body. The Hilti T#-60-ATC-AVR’s power and speed is even more clear in our drilling test.

DEWALT gets kudos for being competitive in this category with a powerful rotary hammer that is comfortable to use. But ultimately falls short to Makita’s comfort and Hilti’s power. The D25603K was just behind the two aforementioned models and overall our team was impressed with it’s performance chipping.

Drilling Speed Winner – Hilti TE-60-ATC-AVR

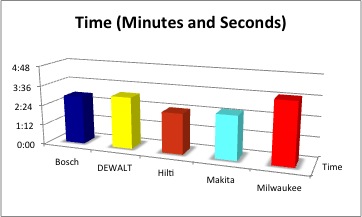

To evaluate speed we timed how long it would take our operators to drill five 4″ holes. We had three consistent operators for each drill and averaged the times of the three heats for a final median speed. Each drill was outfitted with a SDS MAX 1″ x 12″ x 17″ 4-Cutter Centering Bit provided by Milwaukee as a control measure.

The times are displayed in the bar graph below:

Hilti came out on top in this test with an average time 11 seconds faster than the next competitor. This evaluation of the tools really highlighted the power and speed of the TE-60-ATC-AVR, removing the misguided perceptions of our operators and focusing on the empirical data. Not far behind was Makita’s HR4013C with a time of 2 minutes and 37 seconds. And finally Bosch gets on the scoreboard with it’s RH540M clocking in at 2 minutes and 54 seconds.

The chipping and general use evaluations of this head to head are certainly valuable but the lion’s share of this tool’s workload will come in the form of drilling holes, so this category is an important one to selecting the overall winner of this head to head. And not surprisingly the two front runners came out on top, with small margins between them.

Dust Control and Vacuum Integration Winner – DEWALT D25603K

We named DEWALT the winner in this category for it’s innovative suction ring designed to cling to the work piece and remove dust at the source. This dust control strategy avoids awkward modifications to the actual tool set up and allows you to see the drill make contact with the work piece, which is often an issue with other shrouded dust control systems.

We want to note that Bosch has a similar system but it was not provided for our head to head testing. This type of system is clearly the future for dust extraction, but it still has some shortcomings namely the connection to the work-piece can be adversely affected by the surface of the concrete, works well on smooth clean material, but the suction bond struggles on irregular surfaces.

Hilti is a notable model in this category with a high quality dust control system featuring heavy duty plastic and rubber components. This system is shroud based unlike the DEWALT but when tested, performed exceptionally removing all dust from the environment.

Operational Anti-Vibration Winner – Makita HR4013C

Throughout the course of our test, whenever one of our team members stepped up to the Makita inevitably they would look up and comment about the comfort and feel of the HR4013C compared to the rest of the field.

The Makita SDS Rotary Hammer transferred noticeably less vibration during chipping and drilling according to our team. This model features Makita’s Anti-Vibe Technology (AVT) which in this tool combines air actuated counter balance, vibration absorbing housing, and an integrated damper spring at the base of the impact bolt.

Ultimately the Makita HR4013C easily took this category.

Hilti’s TE-60-ATC-AVR which still showcased top of the line Anti-Vibration to our operators and was also consistently rated the second most comfortable model to use. Then by a bit of a wider margin the DEWALT D25603K rounds out the top three.

Value Winner – DEWALT D25603K & Makita HR4013C

Performance, features, and specifications are great reasons to purchase a tool, but when it comes down to spending your hard earned dollars, cost is just as important, if not the most important factor when investing in a new tool. We split this category between DEWALT and Makita, as both models deliver great performance, great operational features, and great safety features at a GREAT price.

Both the DEWALT DC25603K and Makita HR4013C average in cost at about $590.00 almost $200 more than the most affordable models in the head to head, but clearly give the user more for their money. As we mentioned previously the Hilti has a steep price compared to the rest of the field and the two winners of our head to head can go toe to toe with the Hilti, at a much more affordable price.

Overall Winner – Makita HR4013C

Makita took this Head to Head with superior AVT, great operator interface, and a few innovative features sprinkled in to top it all off. This tool performed exceptionally well in almost all categories, was a favorite among the crew, and is significantly more affordable than our number two model the Hilti TE-60-ATC-AVR.

The Hilti dominated the speed drilling test and performed consistently in every category. This is a fantastic SDS Hammer Drill, powerful, fast, and well worth the big ticket price tag. This is a tried and true model and a definite consideration for your hammer drill purchase, Hilti is the first name in SDS Hammer Drills, but still number two in our head to head.

Rounding out the top three again is DEWALT’s D25603K, it delivers some solid features and great performance overall, but was consistently overshadowed by Makita and Hilti. Still a solid tool, that is powerful, comfortable, and features great dust extraction accessories. Another definite consideration for your SDS Rotary Hammer needs.

Specifications & Features

Bosch RH540M

Features:

- SDS-max bit system

- Combination dual mode selector

- Vario-Lock rotates and locks chisel into 12 different positions

- Designed so a qualified service technician can quickly replace the brushes and cord

- 360° Auxiliary handle

- Integral clutch disengages torque transmission if the bit gets into a bind situation

- Grounded design, CSA listed, complies to OSHA

Specifications

- Amperage: 12 Amps

- Cord Length: 8 ft

- Height: 10.5″

- Impact Energy/EPTA (ft. lbs.): 6.1 Ft. Lbs.

- Length: 19″

- Max. Hole Diameter in Concrete: 1-9/16″

- Max. Hole Diameter in ConcreteCore Bi: 4″

- Max. Hole Diameter in ConcreteThru Ho: 2-1/2″

- No Load BPM: 1,500-2,900

- No Load RPM: 170-340

- Optimal Concrete Capacity Range: 1/2″ – 1-3/8″

- Rating: 120V

- Voltage: 120V

- Warranty Limited: 1 Year

- Weight: 15.2 lb

DEWALT D25603K Read our full review here: DEWALT D35603K Hammer Review

Features

- Holes in concrete and masonry from 12 to 45 mm in diameter. Core drilling up to 100 mm

- Chain drive with an oil filled gearbox to ensure total component lubrication and heat dissipation

- Active Vibration Control system with a floating rear handle and damped side handle

- Ultimate Torque Control (UTC) which switches off the tool within a fraction of a second in a stall situation

- Patented two stage clutch to provide maximum protection to the user

- Rotation-stop for medium-light demolition applications

- Unique dust sealing protection delivering high durability and extended tool life

- Hammer mechanism is optimised by reducing the number of components and by improving dampening

- Efficient mechanism delivers impact blows directly to the bit without losses through excessive vibration

- Ergonomic, compact and slim line design

- Electronic variable impact energy/speed

- Lock-on switch for greater control when in chipping mode

- Magnesium housing for lower weight

- Electronic service and brush wear indicator

- Power to weight ratio: 8 Joules of impact energy delivered by a 6.9 kg hammer

Specifications

- Power Input: 1250 Watts

- Power Output: 615 Watts

- Load Speed: 210-415 rpm

- Blows per Minute: 1430-2840 bpm

- Impact Energy: 12 J

- Tool Holder: SDS-Max Morse Taper

- Max. Drilling Capacity [Concrete]: 45 mm

- Max. Drilling Capacity [Breakthrough bit]: 65 mm

- Max. Drilling Capacity [Core bit]: 100 mm

- Weight: 6.9 kg

- Length: 477 mm

- Height: 245 mm

- Width: 104 mm

- Hand/Arm Vibration: 8.7 m/s2

- Uncertainty K 1 (Vibration): 1.5 m/s²

- Hand/Arm Vibration – Chisel: 6.8 m/s²

- Uncertainty K 2 (Vibration): 1.5 m/s²

- Sound Pressure: 93 dB(A)

- Uncertainty K 1 (Sound): 3 dB(A)

- Accoustic Pressure: 104 dB(A)

- Uncertainty K 2 (Sound): 3 dB(A)

- Impact energy (EPTA 05/2009): 8 J

Hilti TE-60-ATC-AVR – Read our full review here: Hilti TE-60-ATC-AVR Combihammer Review

Features

- The Active Torque Control (ATC) stops the motor if the bit binds and the housing begins to rotate too quickly

- Active Vibration Reduction (AVR) optimizes comfort and productivity

- Virtually dustless coring and chiseling with the new, optional dust removal system

- Improved performance in large coring applications up to 4″ in masonry and unreinforced concrete

- Ruggedly built for a long lifetime

- Drilling anchor and through-holes in concrete and masonry 1/2″ – 4″, recommended diameter 5/8″ – 1-1/2″

- Medium-duty demolition work

- Coring in masonry and concrete with TE-Y BK core bits up to 4″ diameter

- Coring in masonry with optional DD-TE-Y adapter HDMU core bits up to 4″ diameter

Specifications

- Rotation speed gear 1 under no load: 350 rpm

- Full hammering frequency: 3300 impacts/minute

- Single impact energy: 5.4 ft-lbs

- Hammer drill bits (optimum dia. range): 11/16 – 1-9/16 in

- Chiseling function: Yes

- Active Vibration Reduction: Yes

- Active Torque Control: Yes

- Dust removal module: TE DRS-Y (optional)

- Max. chiseling performance: 55 in³/min

Makita HR4013C

Features

- 11 AMP motor delivers 8.4 ft.lbs. of impact energy

- Anti-Vibration Technology (AVT®) reduces vibration resulting in a low 5m/s2

- Air actuated counterbalance

- Vibration absorbing housing

- Integrated damper spring at the base of the impact bolt

- Lock-on or trigger activation in “Chipping Only” mode with a push button start/stop control

- Constant speed control

- Soft start suppresses start-up reaction

- L.E.D. service light notifies the user approximately 8 hours before the brushes need to be replaced

- L.E.D. power light indicates switch failure or cord damage

- Variable speed control dial

- Torque limiting clutch engineered to prevent gear damage by automatically disengaging gears if the bit binds

- Sequential impact timing delivers timed hammering during rotation to minimize overlapping bit impacts

- Automatic brush cut-off protects commutator from damage for longer tool life

- 2-mode operation for “Chipping Only” or “Hammering with Rotation”

- 24 bit angle settings allow the bit to be set at different positions for operating convenience

- One-touch sliding chuck for quick bit changes

Specifications

- Amps: 11

- Capacity (concrete): 1-9/16″

- Impact Energy (Joules): 11.4 J

- No Load Speed: 250-500 RPM

- Blows Per Minute (variable speed): 1,450 – 2,900 BPM

- Bit Type: Accepts SDS-MAX

- Overall Length: 18-11/16″

- Cord Length (ft): 16.4′

- Net Weight: 15.1 lbs.

- Shipping Weight: 21.99 lbs.

Milwaukee 5317-21

Features

- 10.5 Amp Motor: Delivers 450 RPM and 3,000 BPM

- Hammer Mechanism: Delivers 5.5 ft-lbs (7.5J) of impact energy

- CPT™ – Constant Power Technology: Delivers consistent performance

- Mechanical Clutch: Protects the tool when the bit binds up

- 2-Mode Operation: Rotary hammer and hammer only for maximum versatility

- 12-Position Chipping Adjustment: Allows the user to maintain the desired hammer position

Specifications

- Length: 17-3/8″

- Weight: 15 lbs

- Voltage: 120V AC

- Tool Warranty: 5 Years

- No Load Speed: 450

- No Load BPM: 3,000

- Cord Type: Grounded

- Electronic Feedback: Yes

- Bit Shank: SDS Max

- Blow Energy: 5.5 ft lbs

- Clutch: Yes

- Drilling Mode 2-Mode: Rotary Hammer and Hammer Only

- Handle Style: Drop Motor

- Vibration Reduction: No

- Thick Wall Core Bit Capacity 4″

- Cord Length 13′

- No Load RPM 0-450

- Amps 10.5

- Trigger Lock No

- Solid Bit Capacity 1-9/16″

About the author

46 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Great review Rob, I’m curious if you were given the new Bosch dust collection system to try which I think is similar to the DeWalt system where it collects it at the bit. It does look like you got the new vac – sweet!

These are the ones I was asking about:

http://www.boschtools.com/Products/Tools/Pages/BoschProductDetail.aspx?pid=HDC200

http://www.boschtools.com/Products/Tools/Pages/BoschProductDetail.aspx?pid=HDC250

http://www.boschtools.com/Products/Tools/Pages/BoschProductDetail.aspx?pid=HDC300

They sent the new system after our testing date. We mentioned that in the article.

[…] Hammer, their newest rotary hammer, through some field testing. The testing was part of our Best SDS Max Rotary Hammer Drill – Head to Head […]

[…] the test on 10″ Reenforced Concrete Bridge Decks. This is the same location we conducted our 1-9/16″ SDS Rotary Hammer Head to […]

why used and compare small milwaukee 5317-21? why it’s not kango545s?

/unfair

Each manufacturer was contacted and asked to supply a hammer. They all knew which hammers we were testing from the other Brands. Milwaukee chose that particular hammer to compare to the others.

Hello. I’m a plumber looking for a good rotary hammer. Mostly used for chipping concrete. I have always been a milwaukee guy, but I am on the fense about dewalt.

Which do you recommend and why?

Dewalt D25501kr or milwaukee 5317-21

Ron – Tough question! To get a better picture you need to look at a couple things. First of all, when you compare the two tools, the DEWALT is a bit more powerful, larger motor, more impact energy. On the other hand, sounds like you’re considering a factory refurbished vs a new unit, so that’s something to consider.

Honestly, if you are only chipping concrete a few times a month, I can’t see much difference. If you were chipping every day, i’d probably go with the DEWALT as it has a more robust anti vibration package.

Both companies offer great service and support, and they both build high quality tools. Good luck.

[…] we plugged larger tools like our Makita HR4013C Rotary Hammer, into the 110v vacuum outlet, we tripped 15amp breakers. A grinder will do the same. To avoid […]

[…] we plugged larger tools like our Makita HR4013C Rotary Hammer, into the 110v vacuum outlet, we tripped 15amp breakers. A grinder will do the same. To […]

I am looking to replace some of our rotary hammer drills and would like to know which you feel have the best safety features. I am familiar with the DeWalt e-clutch but have not been able to try the Makita or Milwaukee brands. We primarily drill through basement walls for gas line installation and have had some injuries as a result of the bits binding up. Would like to stay around the 15lb range in weight. Thanks

Jeremy – The DEWALT, Makita, and Hilti offer great anti-vibration features in this class. The DEWALT in my opinion offers the best clutch for preventing bind up injuries. When you look at price, along with that feature, I believe it’s a great option.

Good luck!

Thanks for the follow up. I really appreciate it.

Hello, great site! I am looking at a new rotary hammer drill, I am a Professional Pest Control Technician. I do Termite work and I can at some jobs go from just 10 holes to 100+ in a day, we currently use a very old Black & Decker Macho V 1½” 6.6A, RPM300, BPM2800, 750W, Weight 13.5lbs.

I’m looking for something that could drill better than this. We have a friend that is a Milwaukee rep and he said we can get a good deal through him. I don’t think I would need a big 1-9/16″.

Also do you have any recommended drill bit’s that you like? More durable/faster? we use DEWALT DW5711 5/8″ x 17″ Masonry Drill bit’s.

[…] NH quarry again this year, which was the site of our first SDS-Plus drill bit comparison and our 1-9/16” SDS Rotary Hammer Head to Head to evaluate the speed and endurance of these 3/8” bits on a heavy duty substrate; 10” […]

Great reviews – I have a unique question

I instal ground screws. Our hand held unit is powered by a SDS Max “Hammer Drill”. The problem is we need the power of the drill, but need the hammer feature off. We also need reverse.

Is there a drill out there that can do this?

Chris – Interesting question. As far as I know they all are either chipping only mode, or hammer drill mode.

Hello, great article!!, why you mention milwaukee tool but there are no results about the performance?

i’m currently deciding between makita and milwaukee would be nice to see some comparison between this two brands.

regards.

Milo – If you read each section of the article, you’ll notice that Makita did better than the Milwaukee. However, there’s a pretty big price difference as well. Really comes down to how you’ll use the tool, and which features are most important to you.

Relatively new to hammering. Article helps a lot but how do I determine how big a hammer I need to unearth and break up some easy, some very hard basalt (lava) boulders (Captain Cook, Hawaii?) Some combination of hammer, chisel, drill, dig, , lever, hammer, chisel drill, dig, ad nauseam. Its dizzying just taking one brand on amazon today the

DEWALT D25501K 1-9/16 is 347

DEWALT D25601K 1-3/4 is 488

DEWALT D25603K 1-3/4 is 584 clutch is 96 more

DEWALT D25721K 1 7/8 is 700

DEWALT D25723K 1-7/8 is 849 clutch is 149 more

DEWALT D25761K 2 is 869

DEWALT D25763K 2 is 950 clutch is 81 more

Keith – Boulders are tough…I’m not familiar with basalt….if it were here in NH…I’d rent a large electric breaker hammer for that type of work vs one of these smaller rotary hammers. These are for minor chipping operations and most importantly drilling. If you only have some small rocks, then one of these might be ok…but I wouldn’t tackle huge rocks.

Thanks. Its slow going because there’s soil, small rocks and an unknown number of bigger rocks. Need the rotary hammer to loosen the soil and rocks around the boulders to free them. Not that many that I need to break down. Grading by hand I guess you could call it. I feel like a pilgrim. I ended up ordering the D25761K on toolnut for 829 and got 2 point chisels, 2 flat chisels and two 3/4 bits for starters (on amazon). Since I’m doing more hammering the extra clutch did not seem like it was worth it. Limited tool rental on the big island so have to get by with what I can use myself.

Thanks for the review! 🙂

Good to see that the expensive Hiltis are not untouchable! (We’ve had one stolen and are looking for a replacement)

Currently I’m fairly keen on Hitachi’s new brushless models (DH40-MEY, DH45MEY and especially DH52MEY (22J!)). They look like great value but unfortunately there are seemingly no independent reviews to find (yet)… Spec. wise they are definitely top of my list; Hilti (second) only wins on marginally lower vibration. But unfortunately specs does usually not tell the full story… ;o)

I purchased a property that is on the New England coastline. During the last Ice Age, the glaciers dumped tons of New Hampshire granite on this property. I am in the process of putting in driveways and the like and am dealing with these little gems. I have been using the feather and wedge technique to split the rocks and am looking to upgrade from a Bosch Bulldog to a larger drill. Due to your article, I am strongly considering the Makita HR4013C rotary hammer. I believe that this will be the best mid-range tool to get the holes drilled into the very hard granite. I have been using 3/4″ and 1″ diameter drills and have been drilling 4″ and 6″ deep holes for this process.I know that my question may be slightly off topic but, can you help me with the best choice of drill bit for getting this job done? Roger

Roger – Sounds like a lot of work! I think for a situation like yours each of the hammer drills we tested would work quite well. The biggest impact in my opinion is buying the best bit you can afford. The big difference in these drills comes into play more for PRO’s who use them day in and day out. That’s where the anti-vibration features play a big part. Also, when it comes to demolition and chipping I feel some have more power than others. But simple drilling they are should be comparable.

Hi you all forget Hilti offer a 2 year no cost period all services and repairs are free for 2 years ….. no cost and then after that you will never pay more than 30% of the tools list price for a repair.

The rest are miles behind

I own the Bosch and Makita, and the Makita is by far the most used one simply because it’s better. I officially became a Makita fan when I accidentally DROVE OVER the drill with a 11,000 pound skid steer. At the end of a brutally long work day we had loaded all the tools we had out into the bucket and was driving it to the trailer when I felt it drive over something. It was dark outside, and somehow the Makita drill had bounced out of the bucket and I had driven over it. 11,000 pounds of weight is usually enough to end the life of any tool, but not this one. The auxiliary handle was bent badly, but only the long screw connecting the two sides of the handle had to be replaced. That was over a year ago and it is still working strong.

Jesus – that’s impressive! If you were to choose between that Makita (1 9/16), 8.4 lbs impact energy, and a lightly used Bosch 1 3/4″ max, 5″ core capacity with a few bits – for the same price, which way would you go?

I work for the City of Parma in ohio and we do our own road work and I currently use Dewalt drills, we are looking for close quarters concrete drilling. My men wanted Dewalt but after your review I leaning to the Makita. Better vibration protection not sure about physical size for drilling into curbs and road sections. Can you advise please. Good review.

Dean – They are so close in size I’m not sure size would be a factor.

Based upon each supplier providing their own RH’s in each class (assuming by regular bit max capacity (excluding core bits etc), I think the review makes sense. However, I’ve noticed that it seemed that Makita had upped the power of their drills while not increasing the max diameter bit. In the past, one could accuse Bosch of doing this in certain sizes (their previous 1 3/4 model, and others). It might seem better to compare either via price or impact energy. What are your thoughts on that?

Secondly – what is the Hilti magic? How do they consistently use less impact energy, draw less amps/watts/power, and still get a faster machine? I think their newest models have changed, from what I have read, and I know you pay extra money for a Hilti, but I’m still perplexed by impact energy stats being almost useless on a Comparison chart of Hilti vs everyone else.

Scott – Great perspective! It’s so hard to get a true apples to apples comparison any more on any tool. Every manufacturer is putting their own spin on the design with what they feel are the most important design features in a given class of tool.

is there a reason you felt you should make this article 10 pages long forcing us to click over and over instead of just listing the information in one long page?

Matt – This is something we struggle with. Some readers prefer the long format (myself included), but some readers want it broken down. We appreciate the feedback and will consider it moving forward. Thanks for reaching out!

I’m also for the long format. But the multipage layout is OK with a proper index drop down so the reader has a decent chance of navigating the pages (see ie. dpreview or tomshardware)…

I am new to the RH market. I am looking to drill 64, one half inch diameter holes. would the Milwaukee be sufficient for this purpose or which on would you recommend. This would be the only big project I would use it for.

How deep would the holes be? It’s likely you could get away with a smaller unit.

Why did you compare a 1 3/4 inch dewalt against 1 9/16 Makita?

Eric – We spent quite a bit of time selecting models based on input from each of the manufacturers. At the time of the test, these were as close to each other as we could get.

I need a recommendation I have 300 7/8 holes 36″ deep in reinforced concrete

It’s going to take days. Which rotary hammer would last thru this ordeal?

Which one would drill the fastest? Any recommendations for type of bit and dust extraction

Jeff – That’s going to be a brutal project, especially when you hit rebar at those depths. You’ll want to get a very good bit that is designed to cut through rebar. I’d use dust extraction at the hole, not the bit, just so you can get the best bit possible. I would probably recommend either the Hilti, DEWALT, or Makita for this application. All three are very strong.

Where is the comparison of Milwaukee?

What a great review, great use of objective measuring standards and not relying on “gut feelings” like other sites. Great photos, easy to read layout, direct & to the point without useless text, and competent testing procedures. Came to your site from google, and this is the first article of yours that I’ve read. Glad to see a competent review site for tools as I’m always asking my self the same questions when I go to buy new equipment. Looking forward to your other posts, – Nick

Thank you Nick. We try hard to create content that means something to all of us in the trades. We’ve got a bunch of these Head-to-Head articles you can read through.

why didnt you use the TE70 ATC Hilti? the TE60 wans’t their top of the line… you used top of the line in all the other brands…

Philip – When we do these Head-to-Head tests we reach out to every manufacturer. We tell them the category and ask them all to submit their best product/solution for the category. We give them parameters on sizes and they have a conversation with us. This test was done several years ago, and I’m not sure what products were out at the time for them. The bottom line is each tool company makes the selection on the product.