Best Hydraulic Oil Impulse Impact Driver – Head-to-Head

Best Oil-Impulse 1/4″ Impact Driver – Head-2-Head

Hydraulic or oil impulse impact drivers are similar in purpose to traditional impact drivers. They are intended to drive small to medium sized fasteners, like small sheet metal screws and up to 3″ decking screws. The big advantage to these tools is that they are significantly quieter than a traditional impact driver, making them better suited for use in occupied spaces and safer for the user’s hearing. Currently there are only a handful of oil impulse or hydraulic impulse drivers on the market.

Why Buy An Oil Pulse Impact Driver?

Oil pulse impact drivers offer reduced noise. Hearing loss impairs quality of life and increases the risk of injury. Every year, thousands of construction workers suffer hearing loss from excessive noise exposure on the job.

According to the CDC: “1 in 8 U.S. Workers Has Some Hearing Loss”. The construction industry comes in a second in terms of most hearing-impaired workers.

Research has shown that 90% of impact driver fastening in most trades is for screws and small to medium lags – 6 to 8 inches long.

Hydraulic drivers are small, compact, and quieter. Here are some torque stats needed for fasteners, all of these fasteners are within the range of an oil impulse impact driver.:

- #9 – 3”deck screw: 40 in-lbs

- ¼” x 3” lag bolt: 53 in-lbs

- 3/8” x 3” lag bolt: 160 in-lbs

- #10–16 x ¾”Tek screw: 10 in-lbs

- 5/16” Bolt: 324 in-lbs

Using a lighter, quieter tool, that has less vibration makes sense, and can result in more satisfied clients and a better user experience. A quieter impact driver would certainly be appreciated in many job sites, especially when working in occupied spaces, such as:

- Homes

- Schools

- Hospital

- Office Spaces

Let’s not forget our own hearing loss. Using a tool that is quieter is better for you to help reduce hearing loss due to long exposure to loud noise.

Oil Impulse Impact Driver Line-Up and Specifications

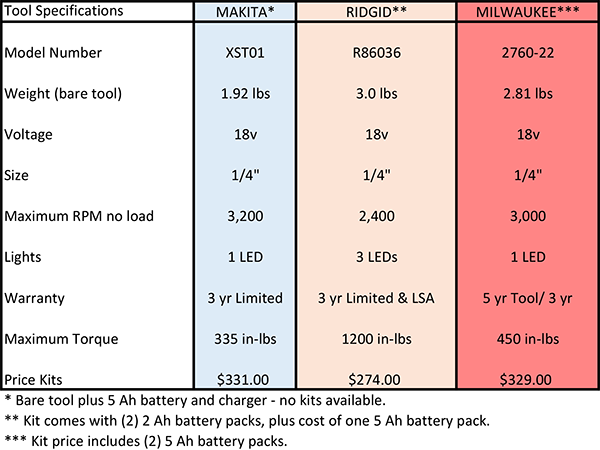

For this Head-2-Head we tested tools from Makita, Milwaukee and Ridgid. We put these tools through two typical fastener driving tasks, and also a more difficult task of driving 4″ TimberLOK screws into sandwiched LVL (engineered lumber) to see how they stand up to a much more demanding driving task. Below are the basic specifications for each oil-impulse impact driver:

Makita XST01 Oil Impulse Impact Driver

- 18V

- 5.0 Ah Battery Pack

- 3200 RPM, 335 in / lbs

- 1.92 lbs bare tool

- 3 year limited warranty

- Makita XST01 Product Info

Milwaukee Surge 2760-22

- 18V

- 5.0 Ah Battery Pack

- 3000 RPM, 450 in / lbs

- 2.81 lbs bare tool

- 3 year limited warranty and limited service agreement, if you register the tool.

- Milwaukee Surge 2760 Product Info

Ridgid Stealth R86036

- 18V

- 5.0 Ah Battery Pack

- 2400 RPM, 1200 in / lbs

- 3.0 lbs bare tool

- 5 year tool warranty / 3 year battery

- Ridgid Stealth R86036 Product Info

Oil-Impulse Mechanism

What are Oil-Impulse Drivers?

A regular impact driver is different from an oil-impulse driver in the manner in which it applies force. Regular impact drivers create their force through a spinning anvil and hammer mechanism. The hammer mechanism compresses a spring, when released, the energy drives the hammer down while simultaneously twisting it. This concussive force is what makes an impact driver a go-to tool for fast fastener installation. The loud chattering noise that they make, is created by the metal to metal parts slamming against each other. This type of mechanism also creates vibration.

The oil-impulse impact driver utilizes oil to hydraulically drive the impact mechanism for lower noise. It has a completely different impact mechanism, similar to a vehicle clutch. Two blades are held by the “anvil” enclosed in a cavity containing viscous oil, which hydraulically forces the two blades to make contact with the spinning outer case or “hammer”. As these components engage and disengage, they hold their impact longer than a traditional impact, resulting in a quieter application with longer, sustained torque, with less vibration.

Benefits of an Oil-Impulse Driver

Oil impulse drivers offer three important features:

- Quieter to operate

- Smoother performance, less vibration

- Increased durability by minimizing reducing metal on metal contact inside tool

Oil-impulse drivers cut down on the noise intensity by as much as 50 percent, as well as reduce vibration for the operator. The less vibration is best explained as a “smoother-feeling” tool to use. The defining feature of this (and any other) oil-impulse driver is how quiet it is compared to impact tools.

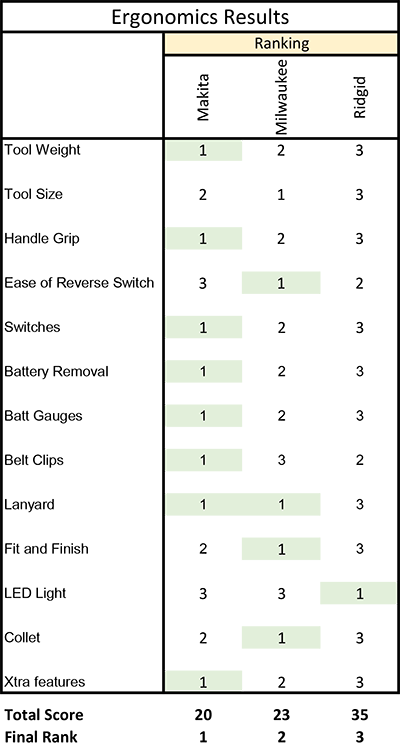

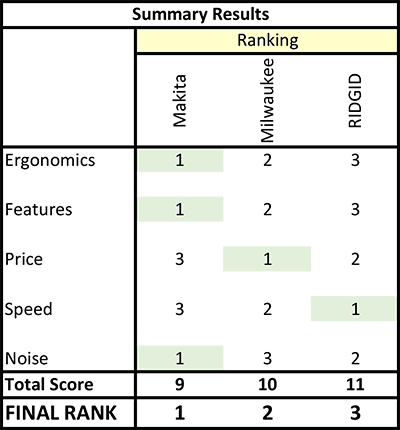

Features – Winner Makita

In the Features evaluation we looked at the following: LED light, controls, clutch, chuck, fit and finish, battery gauges, lanyard and belt clips in this category. We used the same ranking scale as the ergonomics section for consistency.

Reverse Switch

The “Reverse Switch,” on all three tools is located in the same spot, but not equal. The Milwaukee reverse switch was better. Milwaukee’s switch is the only one that recesses in, and seats flush with the impact housing. The crew liked this, because it did not stick out and rub against the web of the operators hand, causing irritation.

Speed Selector Switches

Makita has an LED array, it’s easier to see, and its electronic button is off to the side, allowing the user to see the selections they are making. Makita has a nice positive switch. With the Milwaukee, you have to reach over what you are trying to see to activate the button. The Ridgid has an electromagnetic switch [1-2-3] on the top of the unit.

Battery Gauges

All three tools have battery gauges. The Makita battery gauge stayed on the longest of the three, was bright and easy to see. The LED on the Makita is located on back side of the battery, which the team unanimously agreed is the BEST location.

LED Light

Every cordless tool these days seems to have an LED light, so the manufacturer can say “we have an LED light.” The real questions to ask are:

- Is the LED bright?

- Does the LED cast a shadow?

- How long does the LED stay on?

- Can you turn the LED light on from a separate switch?

Ridgid has 3 LED’s around the collet, completely illuminating the work area with no shadows. There is also a switch on the Ridgid activates the LED, separate from the tool trigger. Makita and Milwaukee both have a single LED, located above, and activated by the trigger. We observed that these single LED lights create annoying fastener shadows. All three tools can activate the LED with a trigger pull, and stay on after the trigger is pulled, we timed them, and they were:

- Milwaukee – 11 seconds

- Makita – 10 seconds

- Ridgid – 10 seconds and has a separate switch to operate and control this LED

Collet

All three impacts have a collet that allows one-handed loading. One-handed loading is easier to use, and more efficient. Milwaukee’s collet seems more durable, solid, and had a tighter spring. It has a a more aggressive knurling which allow using with gloves easier. The Ridgid has a smooth finish which makes it slippery and difficult to use with gloves.

Metal Screw Starting Feature

The Makita and Milwaukee tools both come with a special feature for driving smaller fasteners, like self tapping screws in sheet metal. On the Makita it is called “T mode” on the Milwaukee it is called “Self-tapping screw mode.” These modes start off in high speed, but electronics in the tools sense when the screw grabs, and slows down drive speed to prevent stripping the screw through the metal. This feature is really great for mechanical, electrical, and plumbing professionals, or anyone who needs to drive sheet metal screws.

Neither the Makita nor the Milwaukee stripped a fastener during our testing. The Ridgid, does not have this feature, and during our testing, we stripped 2 out of 10 fasteners when driving in high speed.

A trades-person who regularly uses the Ridgid to install self-tappers, might be able to drive that number down, but the Makita and Milwaukee sure make it a real Fire-And-Forget process. ~ Ethan Bickford [TBBCrew]

Ergonomics – Winner Makita

We looked at 13 aspects of these tools to determine our winner in the ergonomics category. Everything from tool weight, to the quality and usability of LED lights. When it came down to choosing a winner – the Makita won!

Makita is lightweight, has well thought out controls and premium features. We especially liked Makita’s 3-speed selector with Quick Shift Mode™ which controls fastening speed and application.

The Milwaukee finished second in ergonomics, placing second in many categories but standing out with the easiest to use and least obtrusive forward/reverse switch, tight fit-and-finish and the easiest to use collet of the three tools we tested.

Lastly, the Ridgid stood out with it’s triple LEDs, just behind and evenly spaced around the collet, and it’s on-handle LED light switch so that the lights are on any time you pick up the tool. The Ridgid, however, has a smooth and slippery collet, is heavier than the other two, and it’s larger size kept it to the back of the pack.

Why is the Ridgid Stealth SO MUCH Bigger?

Ridgid is notably larger than the other two impacts. This is based on two reasons:

First, Ridgid utilizes older impulse technology, which requires a larger impact mechanism.

Second, Ridgid designed their impact to be able to handle larger sized fasteners, and have a higher torque. Both Makita and Milwaukee are smaller in size, and are optimized for small to medium sized fasteners. The size trade-off is that Ridgid has a much larger tool, with more reactionary torque.

Interesting fact

Milwaukee first started chasing this larger impact technology, but later abandoned it after seeing the Makita technology. It’s fair to say that Milwaukee’s design was inspired after Makita “paved the way.”

Price – Winner Milwaukee

Below we’ve included the current pricing (at the time of publishing this article). The lowest price isn’t always the best in our opinion, we’re always looking for the best value. Our theory is that these impacts are so close in performance that the highest priced tool does not always mean the best tool, same goes for the lowest price. Its a fact that if a lesser priced tool can solve the same problem, and do the same job, isn’t that better?

It’s always hard to compare the pricing of cordless tools especially when each manufacturer packages them differently with kits, bare tools, and then varying size batteries. We show the prices of the tools as tool-only, and kitted.

- Makita $331

- $172 for the bare tool

- $159 charger battery combo

- Ridgid $274

- $199 for kit that includes (2) 2 Ah battery packs and charger

- $75 for one 5 Ah battery pack (hard to find as they are phasing out)

- Milwaukee $329

- Model 2760-22 offers a kits with two (2) 5 Ah battery packs

Buy Now From Our Sponsored Retailers

Selecting the winner of this category was tough. Ridgid is the cheapest and you’d have 3 battery packs, a couple small slim packs and one large pack. Milwaukee is only $55 more, and you’d have two 5 Ah packs. We think we’d rather have two large packs than 2 small and one large. So we think the Milwaukee is the best price/value especially with a hard case.

Oil-Impulse Impact Driver Testing Procedures

Before we describe the tests we conducted, we wanted to talk a bit about sound-level test procedures.

As you know, sound measurement and reporting is a highly precise scientific process. Because sound is measured in a logarithmic decibel scale, the numbers are important. Our readers know that a difference in an additional 10 db is a doubling of the sound energy.

Manufacturers test and report their sound readings in a specialized anechoic chamber with multiple high-precision microphones placed around the test tool. Manufacturers record the sound in careful and controlled conditions under strict test procedures. The test group analyze and process the data according to various sound laboratory standards. This laboratory testing yields a very precise and accurate sound value.

The manufacturers’ published sound levels are absolutely accurate. However, these sound intensity levels will not be those that users will encounter in field conditions. Users will hear sound reflections from walls, ceilings and hard surfaces and ambient noise. Users, believe it or not, may slip or strip fasteners with the bit in their impact drivers. These factors will lead to a higher peak sound intensity.

TBB has said many times that we are not a testing laboratory, nor are we trying to be one during our tool tests. We use commercially available, high quality equipment for our measurements. We attempt to keep our tests consistent and repeatable. We urge the readers to focus on the relative values of our test results. Due to the above factors, readers will note that the TBB sound test results will not track to those that the tool manufacturers publish for their tools.

But our consistent testing yields relative differences in tool performance in our comparison tests. On all three tests mentioned below, we used fresh 5.0 Ah batteries.

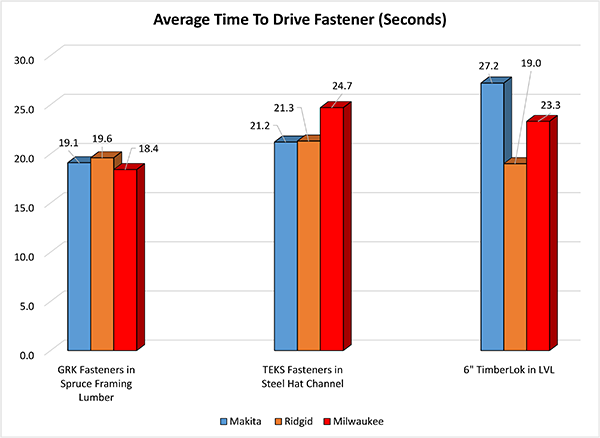

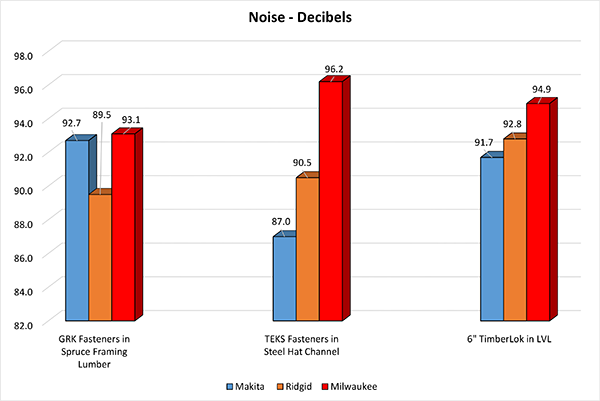

3″ GRK Construction Screws in Spruce Framing Lumber

A common use for impact drivers is to drive fasteners into construction grade lumber. We simulated this condition by driving six (6) 3” GRK construction screws into two layers of spruce 2 x 6 lumber. We attached the two pieces together and clamped the assembly to a solid workbench. We drove six (6) of the GRK screws into the surface and timed the results. In addition, we placed our decibel meter to within 12 inches of the work area and recorded the peak sound energy.

We repeated this test twice, calculated the average run time for two sets of six, and the highest peak sound value (results are shown below). TBB set all three drivers at their highest RPM setting.

For this test, Ridgid was the quietest and Milwaukee the fastest.

TEK Fasteners in Steel Hat Channel

Another popular application for impact drivers is installation of self-tapping metal screws. We selected TEK self-tapping fasteners and drove them into a steel hat channel framing materials. We clamped the steel to the workbench and drove a total of six (6) TEKs into the metal. We recorded the duration for driving all six of the fasteners and recorded the peak sound levels.

For this task the impact drivers were set at their highest RPM setting. In this test, Makita was both the quietest and the fastest.

TimberLOKs in LVL

Manufacturers position oil impact drivers as a quieter/gentler impact tool that is better to use in occupied areas. These tools have less torque than most mechanical impact drivers. While TimberLOKs are a larger structural fastener, they are so prevalent that it’s likely they are specified even in remodeling projects of occupied spaces. So we wanted to see how well the three drivers worked under heavy loads. We figured that driving multiple TimberLOKs into LVL pieces would be a good test for heavy loads.

We pinned two pieces of LVL together and clamped them down to the workbench. Next, we drove four (4) five-inch (5”) TimberLOKs into the LVL pieces. We recorded the time to install all four fasteners and the peak sound measurement approximately a foot away from the tool.

Again, for this test we set all three drivers at their highest RPM setting. Ridgid was the fastest, and Makita the quietest.

Test Measurement Results

Performance – Speed Test – Winner Ridgid

Our first impression when we used this tool was how “smooth” these impacts were, quiet was only noticed later when compared side by side next to a conventional mechanically-driven Milwaukee 2753-20.

Makita and Milwaukee are designed for small to medium sized fasteners. Research shows that 90% of impact driver fastening in most trades is for screws and small to medium lags – 6 to 8 inches long. Users who perform hard joint fastening like lug nuts or 6” Victaulic flanges on water pipe and sprinkler assemblies, would be better served with an impact wrench.

The Ridgd’s Stealth demonstrated the most power and was the fastest driving impact. It performed almost equal to the Milwaukee standard impact, verified by running the Ridgid right next to the standard Milwaukee.

I was impressed by the Ridgid’s power, the only trade off was, it’s reactionary torque can fatiguing over time ~ ROB

Performance – Decibel – Winner Makita

The Occupational Safety and Health Agency (OSHA) has determined safe noise levels and has made recommendations that specific ear protection devices be worn within sound levels of 85dB.

The defining feature of these oil pulse impact drivers is how quiet it is compared to impact tools. Makita averaged 90.5 dB across all three tests. RIDGID was 90.9 and Milwaukee was 94.7 dB.

Makita was the quietest impact driver, it’s impact mechanism even sounds softer when it hits!

Note – An increase of 10 dB is perceived as a doubling of the noise level and represents 100 times more sound intensity. The average of the sound readings for the oil-pulse drivers was 92 dB. This average was 7db less than a standard impact which was 99.8 dB. This 7 dB difference means that the standard impact driver was over 1.5x louder than the average for the oil-pulse drivers.

Finding The Winner

These tests and evaluations, are limited in scope as we’re not a professional testing company. We have limited time to evaluate these tools. We can’t possibly test every application that you might use of one of these impacts for. All three of these impacts have been in service, with our crews, for over a year, and all three are working flawlessly – no negative issues.

Makita and Milwaukee have been designed for the HVAC, electrical and plumbing trades. They are perfect for small to medium fasteners, both are compact in size and have little to no vibration. While they still can install larger fasteners they are not designed for that, and will ultimately be slower.

Makita is higher priced, and sounds softer when it hits. It, too, is designed for small to medium fasteners. It’s a perfect tool for occupied spaces where noise reduction is needed. Ridgid is the least expensive of the lot. It is designed for medium to larger fasteners. It is also larger in size, faster and quieter.

Despite their differences, all of these impacts are able to produce enough power to drive medium sized fasteners.

Best Oil Impulse Impact Driver – Makita

Once again all the tools in this evaluation were close. However, Makita took the win by winning the Ergonomics, Features, and Noise categories.

Final Thoughts

Oil impulse impact drivers are best suited to tasks and workplaces where precision and low noise are more important than having maximum power. For many users, the decision on which impact driver they should buy will likely be based on the battery platform they own. The bottom line is this, all three of these oil impulse impact drivers are capable of performing ALL medium driving tasks. For larger fastening, they will perform the application, but have less torque and will be slower.

Ultimately everyone needs to choose a tool based on their specific needs, uses, and budget.

~ the #TBBCrew

Best Hydraulic Oil Impulse Impact Driver – Video Review

Buy Now From Our Sponsored Retailers

About the author

7 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Compare Milwaukee & Makita to Rigid??!!??

How about comparing Milwaukee & Makita to Dewalt?

I’ve never seen a professional using Rigid crap.

First of all DEWALT doesn’t make a hydraulic oil impulse impact driver. Secondly, lots of guys use Ridgid…including my crews. Ridgid has some good tools. If you haven’t used them then you wouldn’t know.

Any thoughts on why the Rigid greater power as shown in the speed tests, doesn’t come near the actual great torque rating? The Rigid has 3X the torque but nowhere near 3X the speed.

Is the torque rating is for the motor and perhaps not measured at the work? Torque should increase with lower speeds, so maybe a speed difference?

It would be great to see an endurance test too! Not criticising, Your reviews are the best I have found.

Is there really a market for oil impact drivers if 12V impact drivers are stronger and have nearly the same noise level

makita “oil” 335lbs – averaging at 90,22 db

makita “12V” 1200lbs – 94db

Milwaukee “oil” 450lbs – average 94,73 db

Milwaukee “12V” 1300lbs – 96,4 db

Source:

https://www.toolboxbuzz.com/head-to-head/best-12-volt-cordless-impact-driver/

Rudi – There really is no comparison. Hard to explain without seeing an oil impact side by side even with a 12 v.

Do you see this oil impulse technology making it into other tools such as drills, recip & circ saws, or any others you think it might have an advantage?

It’s a great question. Right now I don’t see it happening, but I have to think that every time a new tool is being developed, especially high impact tools, it must be part of the thought process. I do think it has limitations on larger tools but time will tell. Imagine if it could be used in large impact wrenches!