Best Cordless 1/2″ Hammer Drill

Best Cordless 1/2″ Hammer Drill – Head -to-Head

Arguably the most used tool of any trade and probably the most common power tool among homeowners and DIYer’s the ½” cordless drill is as common as it is useful, and versatile. The pistol grip cordless drill was developed by Black and Decker in 1961, but didn’t see consumer use until much later. Since then many manufacturers have contributed to the design and improvements by incorporating lithium ion batteries, hammer drill functionality, and most recently, brushless motors.

For this head-to-head we’ve asked 12 manufacturers to send us their top-of-the-line 18 to 22 volt ½” hammer drill drivers. We asked manufacturers to keep their batteries in the 6.0 Ah range.

The Tool Box Buzz Crew put these drills through the paces with a battery of tough tests to see which is fastest, has the longest run-time, the best ergonomics, and the most power in day-to-day jobsite use.

Hammer Drill Line-Up and Specifications

The 1/2″ Cordless Hammer Drill line-up for our Head-to-Head evaluation includes 12 drills. Below are links to the drills along with basic specifications for each drill:

- Bosch HDH183-B24″ Bosch CORE18V Brushless Brute Tough Hammer Drill/Driver

- 18V Li-Ion

- 6.3 Ah Battery Pack

- 2 Speed Gear Box: 0-500 RPM, 0-2,100 RPM

- 0-31,500 BPM

- Craftsman CMCD721D2 V20* Brushless Hammer Drill Kit

- 20V MAX Li-Ion (18V nominal)

- 4.0 Ah Battery Pack

- 2 Speed Gear Box: 0-600 RPM, 0-2,100 RPM

- 0-35,700 BPM

- DEWALT DCD996P2 20V MAX* XR® Lithium Ion Brushless 3-Speed Hammer-Drill Kit

- 20V MAX Li-Ion (18V nominal)

- 5.0 Ah Battery Pack

- 3 Speed Gear Box: 0-450 RPM, 0-1,300 RPM, and 0-2,000 RPM

- 0-38,250 BPM

- Festool 574708 Cordless Percussion Hammer Drill PDC

- 18V Li-Ion

- 5.2 Ah Battery Pack

- 4 Speed Gear Box: 0-500 RPM, 0-900 RPM, 0-1,900 RPM, and 0-4,000 RPM

- 0-76,000 BPM

- Hilti SF 6H-A22 22-Volt 5.1AAh battery. 1/2 in. Cordless Hammer Drill Driver SF 6H

- 22V Li-Ion (21.6V nominal)

- 5.2 Ah Battery Pack

- 2 Speed Gear Box: 0-480 RPM, 0-1,600 RPM

- 0-22,800 BPM

- Hitachi DV18DBL2 18V Cordless 1/2″ Hammer Drill Kit

- 18V Li-Ion

- 6.0 Ah Battery Pack

- 2 Speed Gear Box: 0-400 RPM, 0-1,800 RPM

- 0-27,000 BPM

- Kobalt KHD 1524B-03 1/2-in 24-Volt Cordless Hammer Drill

- 24V Li-Ion (21.6V nominal)

- 5.0 Ah Battery Pack

- 2 Speed Gear Box: 0-500 RPM, 0-2,000 RPM

- Makita XPH07 18V LXT BL Hammer Drill Kit

- 18V Li-Ion

- 5.0 Ah Battery Pack

- 2 Speed Gear Box: 0-550 RPM, 0-2,100 RPM

- 0-31,500 BPM

- Metabo BS 18 LTX-3 BL Q I 18V 5.5Ah LiHD. 3-Speed Hammer Drill/Driver 5.2Ah Kit

- NOTE: We requested the Hammer Drill version, they sent this version by mistake.

- 18V Li-Ion

- 5.5 Ah Battery Pack

- 2 Speed Gear Box: 0-500 RPM, 0-2,050 RPM and 0-3,800 RPM

- Milwaukee 2804-20 M18 Fuel 18-Volt 1/2 in. Hammer Drill Driver Kit

- 18V Li-Ion

- 5.0 Ah Battery Pack

- 2 Speed Gear Box: 0-550 RPM, 0-2,000 RPM

- 0-30,000 BPM

- Ridgid R8611506B 18-Volt 1/2 in. 6.0Ah Hyper-Octane Cordless Brushless Compact Hammer Drill Kit

- 18V Li-Ion

- 6.0 Ah Battery Pack

- 2 Speed Gear Box: 0-550 RPM, 0-2,000 RPM

- 0-31,000 BPM

- Ryobi P1813 18-Volt ONE+ Cordless Brushless Hammer Drill/Driver

- 18V Li-Ion

- 6.0 Ah Battery Pack

- 2 Speed Gear Box: 0-410 RPM, 0-1,800 RPM

- 0-23,000 BPM

Hammer Drill Test Criteria

When we decide to do a head-to-head test for power tools, we strive to make these tests as fair as possible. That means we ensure we use the same accessories, average out multiple tests, design tests that have repeatable results, and eliminate the human error when possible. The toughest decision is deciding what our test evaluation criteria will be. There are endless testing situations for any tool so we discuss the tool in question and try to develop tests that users can relate to.

For this head-to-head we decided to focus mostly on productivity. In order to do that, we looked at several common uses for hammer drills, along with the speed and endurance in which they operate. The tasks in these tests are common tasks that our crew or sub-contractors perform on a regular basis, so we feel our selection of tests offer a great indication of how productive these tools can be. We believed these tests would provide a good comparison of relative performance to one another.

Head-to-Head Testing Stations

- Performance Drilling Sled: 7/8” x 18” auger bit drilled thru 6” of framing lumber.

- 3/8″ x 6″ TimberLOKs – Average Drive Time to install 6 fasteners in framing lumber.

- 2-9/16 Self-feeding Bit– Average Drive Time to drill 6 holes in framing lumber.

- 3/16 Masonry Bit – Average time to drill 6 holes [preset depth] into precast concrete.

- Ergonomics and features – This is a round table discussion with the entire crew to develop the rankings.

Performance Sled – Auger Bit Drilling – Winner Bosch

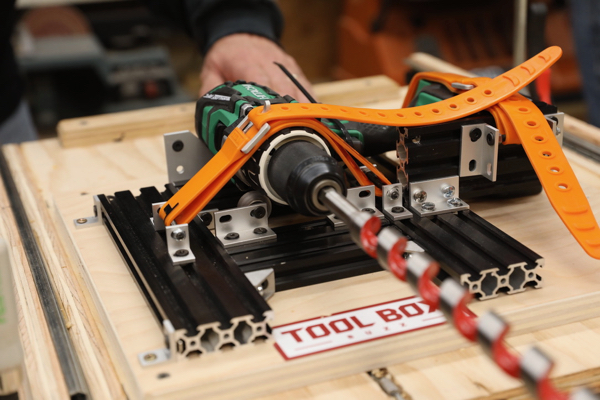

When we begin to pull together our Head-To-Head tool tests, we always try to figure out how to make the tests consistent, repeatable and fair. Often, we figure out how to take the human variable out of a test. We do not want the reader/viewer to wonder if the results of a given test results are due to one of the crew pushing with a different force, or simply being stronger than another crew member.

In the current head-to-head, we discussed how we would test the endurance and performance of the ½” drills by drilling repeated holes with a 7/8” auger bit through a series of four 2×4’s until the drill could no longer bore holes. We knew that the drills would be capable of many dozen holes with each battery charge. This meant that we needed to have a way to hold the drills firmly in place for a long period (in fact, the drill that performed the longest time drilled for about 20 minutes.)

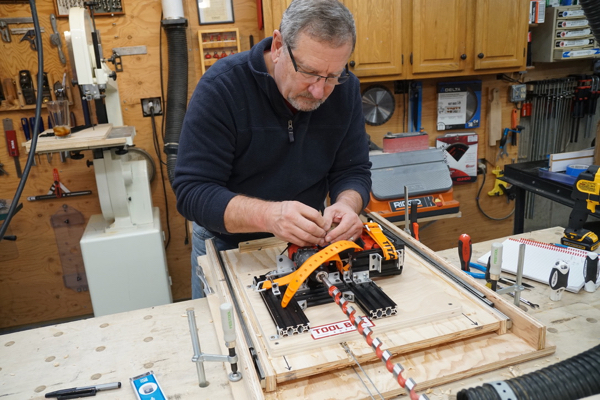

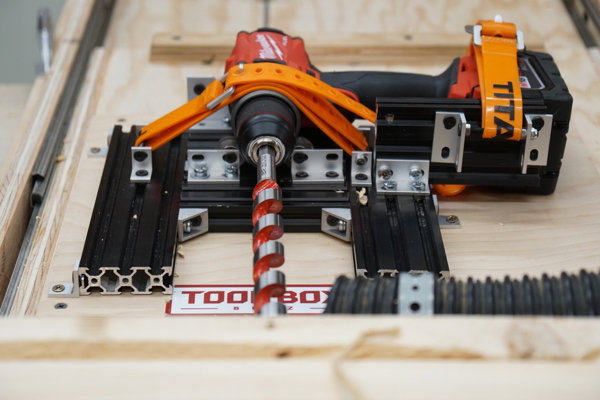

We finally settled on a horizontal sled to hold the drill on its side. The drill was mounted in a fixture and the horizontal movement was provided by a 22 inch set of ball bearing drawer slides. We created the drilling force by a hanging 22 pound weight and transferring the force to pull the front of the sled by using small aircraft cable and a set of pulleys.

We recognized the importance of designing the drill mounts to have the auger bit horizontal and 90 degrees to the wood. The resistance would be substantially greater if the auger went into the wood at an angle in either the horizontal or vertical direction. We also took on the challenge of creating a fixture that would be flexible enough to accommodate the unique shape of each particular drill and allow the jig sufficient movement to position the auger correctly.

The drills were placed in the jig and the adjustments made to level the auger bit. We used Titan rubber straps to secure the drills in the jig and to hold them securely in place. The jig worked very well as we tested 12 drills and on the day of the test, we drilled over 603 holes with the jig.

Performance Sled Results

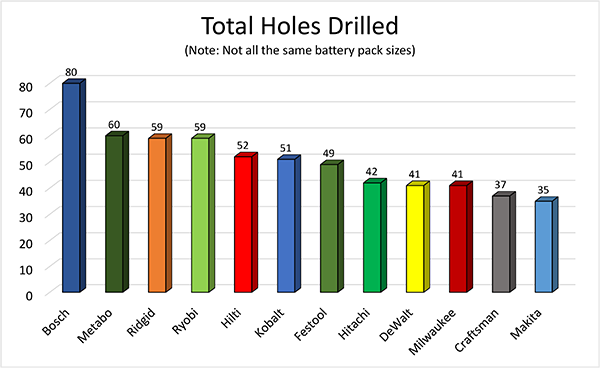

As you can see above in the chart of results Bosch came in first followed by Metabo, and Ridgid and Ryobi tied for third. The most important/realistic result is comparing number of holes drilled per watt-hour. By using watt-hour (total battery pack energy) we level the field for both voltage and amp-hours. Note that the asterisk in the chart are explained in the next section of the article.

Watt-Hours is calculated by multiplying the voltage (actual voltage, not the MAX that some companies advertise) by the battery pack Amp-Hours. This calculation allows us to compare the total energy available to do the work based on both the voltage and size of the battery pack (amp-hours). For example, the Bosch we tested used a 6.3 Ah battery pack running 18 volts. The Watt-Hours is equal to 6.3 Ah multiplied by 18 volts for a total of 113.4 watt-hours.

The Bosch drilled 0.71 holes per watt-hour, followed by Metabo at 0.61 holes per watt-hour and RIDGID at 0.55 holes per watt-hour. In this particular test Bosch was more than twice as efficient at drilling these large holes than Makita at 0.32 holes per watt-hour.

The Bosch ran the longest total time out of all the drills but was the slowest. It drilled for 19.7 minutes, 4 minutes longer than the next best drill, and completed 80 holes. It out-drilled the next highest drill by 20 holes.

Motor Shutdowns

During the auger test, four of the drills shut down after drilling a few holes. In the chart above (Holes/Watt-Hour) the drills that shut down during the test are noted with an (*) after their name on the x-axis. When this happened we had to cut off the zip tie and cycle the trigger. All four tools had sufficient battery charge remaining and all turned back on immediately so we reapplied a new zip tie and continued drilling.

Looking at the data for the auger test the following happened:

- DEWALT shut down 4 times (not including the final shut down)

- Makita shut down 5 times (not including the final shut down)

- Hitachi shut down 1 time (not including the final shut down)

- Craftsman shut down 3 times (not including the final shut down)

After discussing the issue with some of the manufacturers this is most likely caused by one of several factors including high current tripping (most of the drills have electronics that prevent overloading), overheating in the electronics, or voltage drops in the battery pack that are too great to meet the demand of the tool. While this can be quite annoying for the user it’s an important safety factor to protect the tool and prevent damage.

We did not penalize the scoring on these four drill since none of them finished in the top 5 for this test. However, we do feel readers should be aware that some of the drills had this issue, and some were able to do this difficult test with no shut downs. Because these drills didn’t finish in the top of the test results any penalties to the scoring would have been insignificant in the final rankings.

This could be a BIG deal, for guys in the field, as no one wants a drill to shut down, even if it starts again on a quick reset.

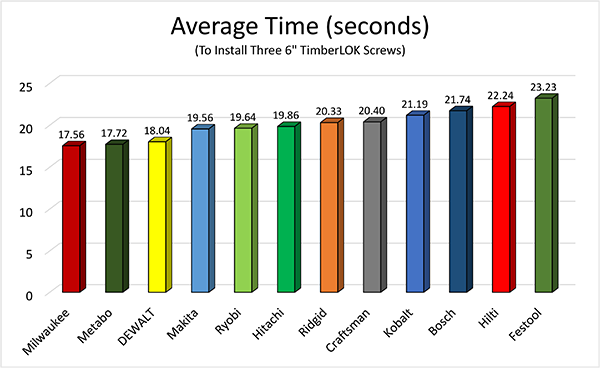

6” TimberLOK Installation Speed Test – Winner Milwaukee

This test was performed using 6-inch TimberLOK fasteners into framing lumber. With today’s advancements in engineered lumber TimberLOK fasteners have become standard on almost all wood framed projects. Examples include timber frame connections, truss tie-downs, and seismic restraints.

This is a task that we feel many of our readers do on a regular basis and it highlights a task that can benefit from improved speed of installation combined with torque resulting in productivity gains. We decided to run these tests with human operators, to get a better feel for the tools torque, and overall ergonomics.

We set the drills on their fastest speed, and had the same users do this test for all the drills to minimize any chance of time being affected by a different user. We swapped out users and retested, taking the average time for all users.

Note: Festool and Metabo were unable to complete this test using their top speed setting. Festool was able to do it in speed 3 (out of 4 available), and Metabo was done using speed 2 (out of 3 available).

The following chart shows the results of this test:

TimberLOK Screw Test Results

The Milwaukee averaged six fasteners in 17.6 seconds and finished in first place. It beat out a win over the Metabo by 1/10th of a second, which came in at 17.7 seconds. Third was the DEWALT at 18.0 seconds. Clearly the data shows a close race for this application. It should be noted that for this test some of the drills were able to drill on their higher speed settings which shows their power and ultimately resulted in faster drilling times.

The MILWAUKEE packs a vicious punch for such a small drill! ~ Stan Durlacher

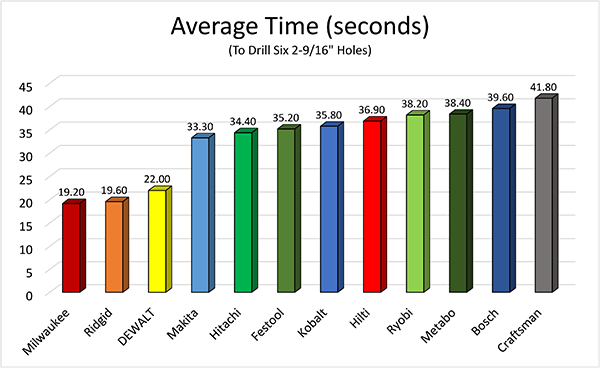

2-9/16” Self-Feeding Bit Drilling Speed Test – Winner Milwaukee

Remodelers, plumbers, electricians and mechanical contractors drill large diameter holes in wood every day. So this large diameter drilling test offers a glimpse at productivity on a strenuous torque demanding task. For this test we wanted to see who can drill the holes the fastest, so each drill was set to it’s highest speed, if it couldn’t do the 6 holes in high speed, we lowered the speed until the drill could do the holes. Obviously drills that have enough power to drill a hole this size in the higher speeds are far more productive. Each drill used a new DEWALT 2-9/16” self-feeding bit.

We had the same users do this test for all the drills, to minimize any chance of time being affected by a different user. We then swapped out users, and retested, taking the average time for all users.

The following chart shows the results of this test:

Self-Feeding Drill Bit Results

This test really showed which tools have significant power to handle high demand tasks. While it was a speed test, we want to note that ONLY four of these tools could complete this test in speed 2, all the others had to perform in their lowest speed 1 setting. Milwaukee, Ridgid, DEWALT and Festool were able to do the test in Speed 2.

The MILWAUKEE didn’t give a damn. It just flew through that test (2-9/16″ self feed in high gear). That drill was like “Hold my beer, man. Let’s do this!” ~ Ethan Bickford

The top three drills stood apart with their performance. The Milwaukee was an absolute beast in this test, and averaged 19.2 seconds to drill six 2-9/16″ holes. The Ridgid was a close second at 19.6 seconds followed by the DEWALT at 22.0 seconds. Impressive performance to say the least!

The RIDGID never ceases to amaze me, they are the hidden gem in the tool industry! ~ Rob Robillard

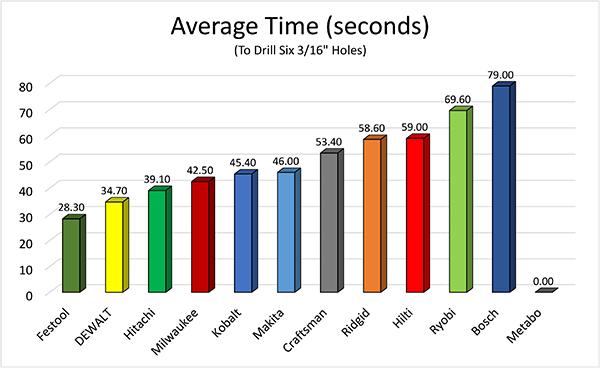

3/16” Masonry Bit Drilling Speed Test – Winner Festool

This task simulates installing Tapcon concrete screws. We used a 3/16″ masonry bit to simulate a 1/4″ Tapcon installation, typical in residential construction and remodeling. We did the test on a section of steam-cured precast concrete curbing.

We took the average time to drill six 3/16” holes 2” deep by the same user. The following chart shows the results of this test:

Concrete Drilling Speed Test Results

The Festool was by far the fastest drill in this test, coming in at 28.3 seconds, 6.4 seconds faster than the DEWALT, and 10.8 seconds faster the third place Hitachi.

Note – Unfortunately the Metabo unit that was send to us was NOT a hammer drill unit, we missed it on initial unboxing, and we were not able to use this drill in this test. So we had to rank it last in this category, which no doubt hurt it’s final ranking in the head-2-head.

Festool is often categorized as primarily a woodworker tool. Festool did not carry this stigma during this concrete testing! The Festool PDC killed the concrete test. Festool is known for making very high quality long lasting tools with some unique features. The Festool PDC is no different, one of our testers said that you can feel the difference between the Festool PDC and the other drills in the test “it’s like driving a Cadillac.”

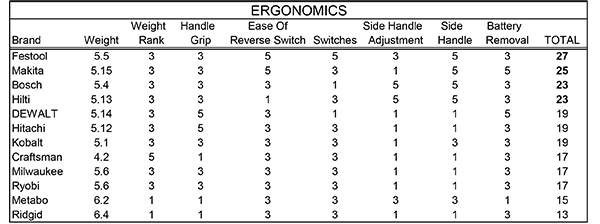

Ergonomics – Winner Festool

The last part of our evaluation included ergonomics and features. For this evaluation the TBB team evaluated all of the hammer drills used during the testing. With everyone on the team using drills differently throughout or normal work day, this was a great way to develop a consensus on which tools we felt were the most comfortable for users.

That Festool is SMOOTH in your hands! ~ ROB

Ergonomics is the most difficult evaluation we ever do because it’s such a subjective process.These companies have all invested a lot of time, money and research into designing their tools to provide superior balance and ergonomics. These efforts can be seen in the time and effort they spend making their tool handles comfortable. Achieving that sweet-spot or immediately noticed “ergonomic feel” is the goal!

As always, the DEWALT felt the most comfortable in my hands. We always say this but they have one of the best grips. ~ Mike Valente

We evaluated several items, such as, the size of the hammer drill, weight, balance, grip comfort, LED lighting and switches.

DEWALT has the nicest grip and best ergonomics hands down and their three-way switch for the LED is what puts it above the rest! ~ Scott Arnold

For this evaluation there were six reviewers with input and feedback for each of the tools. Each tool was graded and rated on a 1-3-5 score, with 1 as the lowest and 5 the best score. We held the 5 score for the tool that was truly outstanding in that category. It’s important to note that these are premium drills and as a result are competing in a tight category.

Ergonomics Results

Festool First Place

The Festool is well-made comfortable drill coming in at 5.5lbs. The team felt that the Festool had an excellent drill rotation switch. The clutch and speed controls are on top of the drill and easy to access. The belt clips (there is one on each side both integral to the drill base) flip out of the way when not in use and are non-marring.

The FESTOOL belt clip is unique, convenient, always there, no tools required, and non-marring. ~ Mike Hopp

Festool stood alone with the best switch set up, and its side handle is well thought-out and durable. It is also one of two drills in the test [Metabo was the other] with a quick release interchangeable chuck. The right angle chuck (available in a kit or separately) is very handy and helps out in those tight spots.

FESTOOL is smooth as butter but expensive as gold! ~ Scott Arnold

Makita Second Place

Like Festool, the ease to operate the drill rotation on the Makita was superior. It too has an excellent side handle and the team felt that it’s battery removal switch and indexing was superior. The team marked the Makita low on its side handle adjustment, which probably kept it from taking first place.

Bosch and Hilti [3rd Place Tie]

The team felt that both the Bosch and Hilti had excellent side handles and their battery removal switch and indexing was superior. The Bosch was marked down on its switch placement and ease of use. The team did not favor the Hilti’s drill rotation switch and its ease of use.

The RIDGID has the only truly shadow-less LED light I’ve ever seen on a cordless drill ~ Ethan Bickford

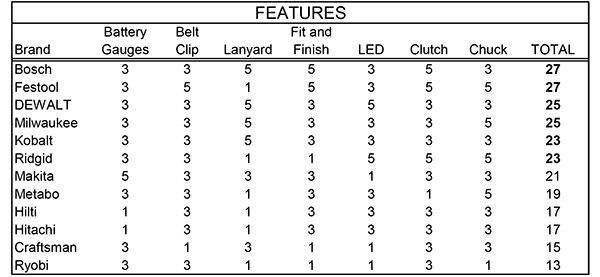

Features – Winners Bosch and Festool Tied

We evaluated LED light, clutches, chuck, fit and finish, battery gauges, lanyard and belt clips in this category. We used the same ranking scale as the ergonomics section for consistency.

The team felt unanimous that the Bosch and Festool both excelled in the features category. These drills fit and finish were impressive, the battery gauge, chuck, clutch and LEDs were also excellent.

BOSCH and HILTI hit it out of the park with their side handle designs and ease of adjustment for the Pro tradesman ~ Todd Fratzel

DEWALT and Milwaukee tied for second place. Both drills performed well in this category, the biggest stand out for the DEWALT was how incredibly bright its LED was, and the fact that you can select low-medium-high speeds. The team was equally impressed with the Milwaukee’s chuck, as it was amazingly smooth to operate.

The BOSCH drill is like having a BMW in your hand. Incredibly well made and exceptional quality. ~ Stan Durlacher

Rounding out the top three was a tie, between Kobalt and Ridgid with features the team felt stood out from the remaining drills.

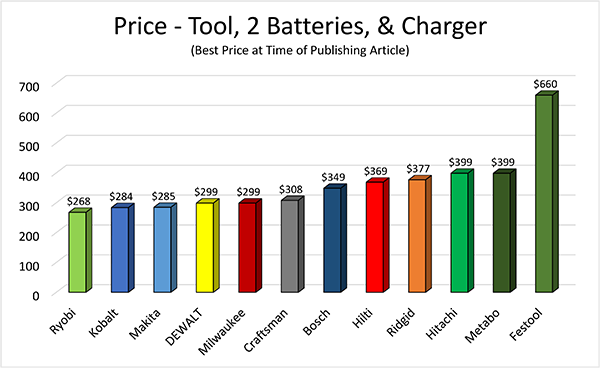

Price – Winner Ryobi

Below we’ve included the current pricing (at the time of publishing this article). The lowest price isn’t always the best in our opinion, we’re always looking for the best value. We ranked each drill based on its lowest price, but its important to keep in mind the value proposition.

Our theory is that many of these drills are so close in performance that the highest priced tool does not always mean the best tool, same goes for the lowest price. Its a fact that if a lesser priced tool can solve the same problem, and do the same job, isn’t that better?

It’s always hard to compare the pricing of cordless tools especially when each manufacturer packages them differently with kits, bare tools, and then varying size batteries. We show the prices of the tools that we tested, that means if the tool did not come as a kit we priced the bare tool, batteries and charger separately.

The Ryobi came as a kit with 4.0 Ah batteries, however they sent us 6.0 Ah batteries in order to be competitive in this testing. As tested, the price came to $268.00. [18-Volt ONE+ Cordless Brushless Hammer Drill/Driver, with (2) 6.0 Ah Battery, Charger, and Bag]

The 1/2-in 24-Volt Kobalt with [2] 5.0Ah batteries came in at $284.00 and the Makita kit just a dollar more.

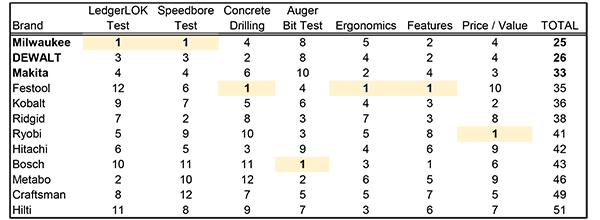

Overall Best Hammer Drill – Winner Milwaukee

These tests and evaluations are very difficult, take a lot of time, and ultimately limited in scope as we’re not a professional testing company and we’ve got limited time to evaluate the tools. We cannot do longer term testing that would shed light on durability and we can’t possibly test every application that you might use of one of these drills for.

However, we feel comfortable that all the hammer drills in this Head-to-Head are good tools and our testing helps bring to light pros and cons for each. In order to choose the BEST ½” cordless hammer drill, all seven [7] evaluated categories were scored and ranked 1 through 12, to define the winner. We then tallied those category numbers to come up with a total number. The lower the number the better.

Milwaukee

The Milwaukee’s’ small package certainly had a big impact, and surprised many of us. This drill came in first on the LedgerLok and Speedbore test – with the fastest drilling and fastening speeds. It has a great price, with decent features, and it’s a drill that commanded a big presence in these tests and impressed the team. Overall this hammer drill shined in combined speed and torque which we feel makes it the king of hammer drills in this evaluation.

DEWALT

The DEWALT, another impressive drill, missed the first place rank by one-point. A solid drill, the DEWALT came in 2nd, 3rd or 4th place in almost every category, with the exception of the auger bit test. It’s a well-priced, durable drill with an LED work light to be envious of.

Makita

Third place went to Makita. The Makita was the sleeper of this Head-to-Head. While it performed poorly in in the auger test with 0.32 holes per watt-hour, it flew in under the radar everywhere else coming in at 3rd or 4th place in almost every other test. When you consider the pricing, along with the performance, we feel the Makita is an outstanding value at $285.00 which includes two 6.0 Ah battery packs and comes in a hard tool case.

That MAKITA is ALWAYS right there, it’s the “Sleeper of the testing!” ~ Rob Robillard

Final Thoughts – Cordless Hammer Drills

For many users, the decision on which 1/2″ Hammer Drill they should buy will likely be based on the battery platform they own. The bottom line is this, almost all of these 1/2″ hammer drills are capable of performing most medium duty drilling and driving tasks.

Ultimately everyone needs to choose a tool based on their specific needs, uses, and budget. With all the data above we feel confident that you can make a better educated decision when you buy your next 1/2″ hammer drill.

~ the #TBBCrew

Buy Now From Our Sponsored Retailers

Best 1/2″ Drill Video Review

About the author

20 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Hi, in the future could you compare the hilti sf 10w-a22 with the same rules?

This model imo is more powerfull than sf 6.

5/5 🙂

Dawid – That model is not a hammer drill. We specifically tested hammer drills. Maybe we’ll do a full size drill/driver in the future.

sure, metabo was nicely selected because of its hammer drill

Hi Rob

Is it possible to list all battery’s and details of the batterys to get a better comparison.

Dennis – I just updated the article this morning and included the Amp-Hour size for each battery pack that we tested.

OK ty

Another question

Are Bosch and Metabo using other cells than 18650s?

Yes I believe they are using 21700 cells. I also think the new 6.0 and 9.0 packs from Milwaukee are using them.

Todd- FYI, the 6Ah and 12Ah use the 21700, but all the other packs use the 18650 cells. Amazing review overall guys! Appreciate the time dedicated and level of detail.

Will you be reviewing an actual metabo cordless hammer drill

They sent the wrong one and our testing is done. Won’t likely redo the hammerdrill for some time.

No Worx HAMMER DRILL? 囧

No…we didn’t include that brand.

Huge fan of Milwaukee and would love to invest into a 1/2″ cordless drill. Unfortunately I read the reviews of the drill linked above,to come to find out a lot of people are having trouble with overheating or a wobbly Chuck. My question is, to your knowledge have you heard or seen these issues with the drill since testing?

Devin – We haven’t had any issues. Like any cordless power tool they can be pushed to the point of having them overheat. Luckily the electronics in the drill won’t allow that to damage the tool, if it gets too hot it will shut down to prevent permanent damage. Several of us have these drills and no one has had any issues.

First, let the accolades fly for a great, objective, comprehensive test set up. I see too many 100% subjective tests and you guys have done the best job I have seen in a long time establishing a fair test protocol. I know this takes time and a lot of pre-planning. Well done!!!

I would love to see you “bolt-on” tests of new hardware for the next year or so since a few new models have arrived such as the Ridgid “Octane” model touting class leading torque specs. What say ye?

Are you suggesting testing new ones as they come out and updating the article? If so that’s likely not in the plans right now. Items like impact drivers, drills, recip saws, etc, will likely get done over again in a year or two as more new models come out. We’re always working on new tests and by time we get those done we’ll be revisiting some of the more popular tools.

HI. In your final evaluation you state that it is about ‘what is the BEST tool’. But because you include the price/value column, in my opinion the outcome is not the ‘best’ tool. If you’re talking about the ‘best’ tool you cannot include price/value. So you should have 2 Total columns, one without Price/value and one with price/value.

Luckily all the data is there…so you can form your own opinion about what is the best. As we’ve said many times, what is best for us isn’t necessarily best for you, but we provide all the data so everyone can use it to come to their own final conclusion.

Interesting comparison, really good work, I’m really impressed with the amount of effort you put in.

I’m not trying to say you have done a bad job, just trying to help give a second point of view and maybe help you do your reviews better. Also maybe show that by changing how you count change the result so significantly which probably means that all brands are pretty good!

I was surprised, being more European based and therefore having more access to Bosch compared to the more American brands like Milwaukee that after watching through the youtube video that Milwaukee won and Bosch was 9:th, almost last! When watching I thought Bosch would do quite well. After trying to analyse your scores more in detailed I wonder why did you not count the first/second test? Total Holes or Holes/watt? not both but at least Holes per Watt, to me feels like a very important test.

If you had included that test Bosch and Dewalt would have shared the win!

Another thing that bothered me was the score per place, I would have preferred to do a percent based score or something, this would have been very complicated, but IMHO better. What I mean is that to get 12 points for 23.23 seconds, compared to 1 point for 17.56, did not compare well with 1 point for 19.2 seconds and 12 points for 41.8.

But to make things simple and fairer you should at least have counted the position like you usually do in sports, so that if you have 2 second place positions the next is 4:th not 3:rd. If you had done that it would still have been Bosch and Dewalt first but Kobalt Third and Milwaukee Fourth!

Thanks for a very well designed review!

Stefan – You prove my point that I say all the time. We publish all the data so you can do your own ranking. We ranked holes per watt-hour for a very important reason, each tool did not have the same size battery pack (watt-hours), essentially if you rank total holes drilled when one tool has a larger “fuel tank” that’s not really a fair comparison. There are many ways to do this, and you did exactly what we hope everyone will do….use our data for form your own opinion 🙂