Best Benchtop Thickness Planer – Head-to-Head

Best Benchtop Thickness Planer

Benchtop thickness planers are an essential piece of equipment for any woodshop. These planers are an excellent option for small home woodshops and contractors that need a portable option. While not big and powerful as full size shop thickness planers, benchtop thickness planers are still very capable of effectively planing a wide range of wood products. Thickness planers allow users to purchase a wider range of raw wood materials (often at cheaper prices) and mill the wood to the exact dimensions needed for a project.

Thickness planers perform 3 important tasks for woodworking and carpentry:

- Smoothing rough stock

- Making the faces of a board parallel

- Bringing stock to a consistent and specific thickness

Thickness planers are primarily a woodworker’s tool, however they are also often used by finish and trim carpenters in the shop and occasionally in the field. With sharp knives the surface of a planed board is often smooth enough for paint or even clear finishes. For our testing we chose the following planers (follow links for manufacturers page on each planer):

- Delta 22-555

- Delta 22-590

- DEWALT 734

- DEWALT 735X

- Makita 2012NB

- Porter Cable PC-305TP

- Ridgid R4331

- Triton TPT 125

For this head-to-head test we focused on planing several different wood species, the surface finish, the power, and pricing. Below is a detailed discussion of our testing and evaluation.

Buy Now

Features and Specifications

Portable thickness planers have to squeeze a lot of power into a small footprint that can be reasonably moved around a shop or to a job site. But even within this limitation there are some substantial differences in size and weight of the machines we’ve tested. But every machine is capable of planing boards 12 to 13 inches wide and 6 inches tall. The specifics and the differences are show in the lists below.

- Delta 22-555

- Weight: 58 lbs

- Capacity (width): 13″

- Max depth of cut:3/32″

- Max stock height: 6″

- No-load speed:9400 RPM

- Number of cutter knives: 2

- Feed rate (feet per minute):28

- Outfeed table length: 6-7/8″

- Delta 22-590

- Weight: 76 lbs

- Capacity (width): 13″

- Max depth of cut: 1/8″

- Max stock height: 6″

- No-load speed: 10000 RPM

- Number of cutter knives: 3

- Feed rate (feet per minute): 26

- Outfeed table length: 12-1/2″

- DEWALT DW734

- Weight: 80lbs

- Capacity (width): 12-1/2″

- Max depth of cut: 1/8″

- Max stock height: 6″

- No-load speed: 10000 RPM

- Number of cutter knives: 3

- Feed rate (feet per minute): 24

- Outfeed table length: 11-1/4″

- DEWALT DW735X

- Weight: 92 lbs

- Capacity (width): 13″

- Max depth of cut: 1/8″

- Max stock height: 6″

- No-load speed: 10000 RPM

- Number of cutter knives: 3

- Feed rate (feet per minute): 14(low) 26(high)

- Outfeed table length: 9″

- Makita 2012NB

- Weight: 62 lbs

- Capacity (width): 12″

- Max depth of cut: 1/8″

- Max stock height: 6-3/32″

- No-load speed: 8500 RPM

- Number of cutter knives: 2

- Feed rate (feet per minute): 27.9

- Outfeed table length: 9″

- Porter Cable PC305TP

- Weight: 64.8 lbs

- Capacity (width): 12-1/2″

- Max depth of cut: 3/32″

- Max stock height: 6″

- No-load speed: 8000 RPM

- Number of cutter knives: 2

- Feed rate (feet per minute): 26.2

- Outfeed table length: 6-7/8″

- Ridgid R4331

- Weight: 79 lbs

- Capacity (width): 13″

- Max depth of cut: 1/8″

- Max stock height: 6-1/8″

- No-load speed: 9000 RPM

- Number of cutter knives: 3

- Feed rate (feet per minute): 23.5

- Outfeed table length: 12″

- Triton TPT 125

- Weight: 64 lbs

- Capacity (width): 12-1/2″

- Max depth of cut: 1/8″

- Max stock height: 6″

- No-load speed: 17500 RPM

- Number of cutter knives: 2

- Feed rate (feet per minute): 19.7

- Outfeed table length: 7″

Thickness Planer Testing Procedures and Evaluations

For this evaluation we used several types of wood in order to get a good perspective on performance. We used the following boards in our testing:

- 1×4 Mahogany decking

- 1×6 White Oak

- 1×6 Hard Maple

- 1 x 8 Poplar

For this bench-top thickness planer head-to-head we evaluated several categories including:

- Pre-Test Inspection and Adjustment – We looked at how level the infeed and outfeed tables were, we adjusted them, and noted how easy or difficult the process was.

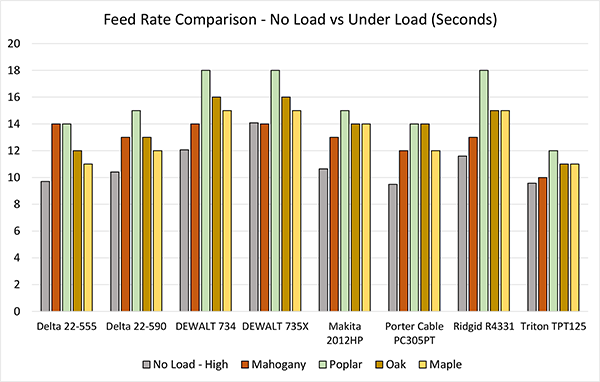

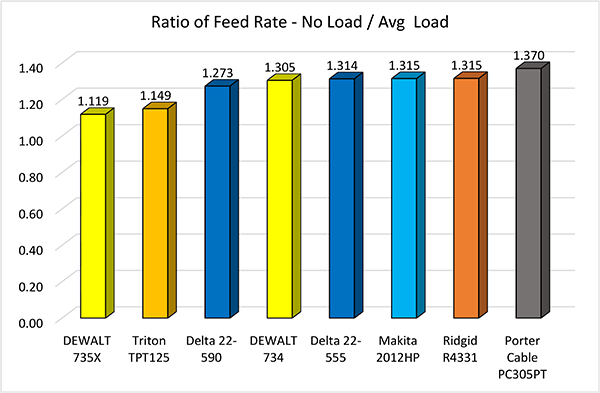

- Feed Rate (Speed) – We measured the no-load feed rate of each planer and compared that to the feed rates under load for different material types. In our opinion this provides a sense of how powerful the motors are.

- Maximum Depth of Cut Performance – For this evaluation we measured the amp draw for each thickness planer under load planing several different types of wood. Again in our opinion this helps compare the strength of the motors during the planing process.

- Depth of Cut Accuracy – For this evaluation we wanted to look at how accurately the planers remove a specified depth. Each planer has a dial that when turned a specified amount will theoretically remove a given depth in a single pass. We compared how accurately each planer was able to remove a fixed depth based on the dial.

- Snipe Evaluation – Snipe is fairly common with thickness planers, especially benchtop models like the ones in this evaluation. We compared the length of snipe for each planer and material type.

- Surface Finish Evaluation – Ultimately the surface finish is really important, especially if the finish reduces the time to prepare the work piece of paint, stain and or clear finishes. We applied blue chalk to the surface of the boards in order to improve our visual inspection combined with a physical inspection (feeling the surface) to rank the surface finish for each planer.

- Blade Change Evaluation – Lastly we measured the time to do a blade change on these planers. Changing blades is a necessary task for any thickness planer so we wanted to see how they compared.

- Warranty Coverage – We summarized all the warranties.

- Pricing – We list the current pricing at the time of publication.

Pre-Test Inspection and Adjustment

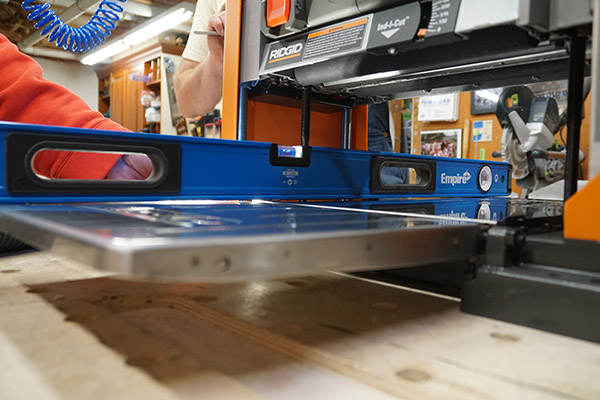

Prior to testing day, we unboxed the bench-top thickness planers and set up the equipment with dust collection manifolds (if so supplied) and put on accessories. In particular, we adjusted the in-feed and out-feed tables to ensure each were level with the planer bed.

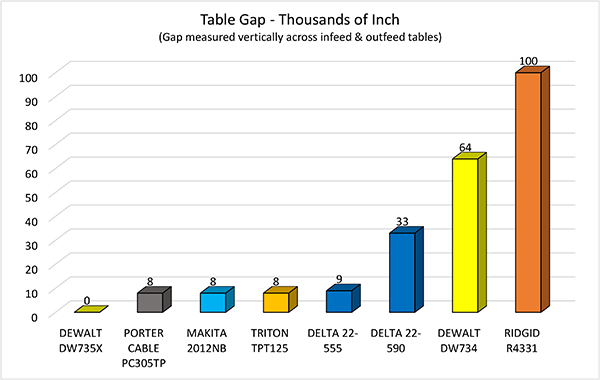

It’s extremely important that the in-feed and out-feed tables are level in order to have consistent and representative tests. The as-shipped accuracy of the tables varied between the different models.We adjusted the in-feed and out-feed tables separately and then checked for level across the entire machine. The worst measured vertical deviation from flat at the edge of the outfeed table nearly 1/8” above the surface of the planer. All of the machines except the DEWALT DW735X needed minor adjustments to reach a level surface.

Most of the planers utilize a bolt to adjust the table vertically with a captured nut to hold the adjustment bolt in place. All of the units had a similar table adjustment but one. We were very impressed with the Makita planer and its setscrew adjustment. The Makita machine had, by far, the easiest adjustment method of all of the planers. The four setscrews were easy to reach and we found it easy to dial in the proper adjustments.

We’re not going to rank this category as we feel a bench-top shop tool like this will always require some setup and fine tuning. Of the 8 planers Makita definitely has the best system for making those adjustments.

Dust Collection

While we didn’t rank dust collection it’s worth discussing briefly. Thickness planers produce high volumes of wood chips and dust, probably more so than most any other tool in the woodshop. All of the planers (with the exception of one) comes with a dust shroud so the planers can be attached to a dust collector. The Porter-Cable does not come with a shroud (a subscriber on our YouTube channel says one is available for the PC from Delta, Delta part number 50-359 , so maybe you can find one). So anyone that is interested in this model should plan on lots of clean up after planing. All of the other planers tested worked well when attached to the shop dust collection with little variation in performance among the different models.

Feed Rate (Speed) – Winner DEWALT DW735X

We recorded the no-load feed rates for each planer. To do this, we adjusted each planers depth until it contacted the wood but had not reached the depth where the cutter blades hit the wood. In order to record the no-load feed rate for a section of wood 45″ long (same length of the samples we’d be running through the planer), we used a longer board (60″) with two marks near each end that were 45″ apart. This allowed us to visually time the 45″ section as it passed by a reference point on the planer. For each planer, we ran this test three times and used the average of these times for a comparison between the no-load and fully loaded feed rates of each machine.

The graphic above shows the no-load feed rate for each machine along with the feed rates of each machine for each sample of wood. We were looking to see which planers had enough power to sustain the no-load feed rates throughout the different boards that were planed.

Above you can see a graphic showing the ratio of the no-load feed rate compared to the average loaded feed rate (average feed rate for the materials we planed). This just gives a good relative comparison of how the motors performed under load. The DEWALT 735X and the Triton TPT125 were able to keep the feed rate much closer to the no-load rate compared to the rest of the field.

We did rank this category as it’s a great way to evaluate the power of the planers. The top three included the DEWALT 735X, Triton TPT125 and the Delta 22-590.

Maximum Depth of Cut Performance

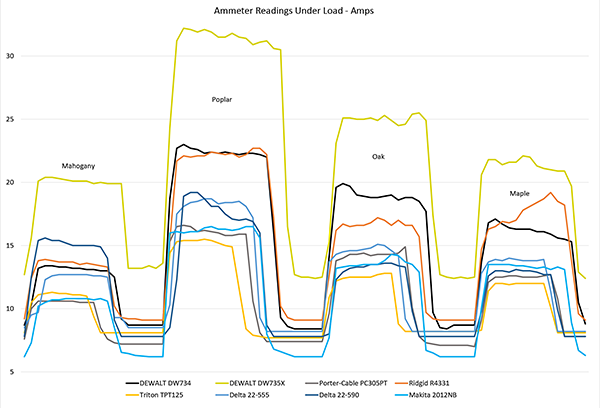

We wanted to know how each machine performed at maximum loads (which results from cutting at the maximum depth in a single pass that the manufacturer recommends). More specifically, we wanted to know which planer pulled more power (maximum amp draw) and which one had the best feed performance relative to its no-load condition.

During this test, we set each planer to its maximum depth of cut (as recommended by the manufacturer) – usually 3/32 inch. We ran four species of wood through the planers and recorded the time for the cut and the amperage profile for each cut. Each wood sample for each machine was 45” in length. This was the same length of the no-load speed test. Our team set up a FLUKE 3001 FC recording ammeter that measured values on a one second interval and sent the data via wireless link to our computer for later analysis.

The wood samples we used in this test were 1×4 Mahogany decking, 1 x 8 Poplar, 1×6 Oak and 1×6 Maple. We knew that the 1×8 Poplar at a maximum cut depth would tax the power of these planers. We also wanted to see how the different hardwoods would exercise the planer capacity.

While we’re not ranking this category we do feel the data is interesting and informative. As you can see above the DEWALT DW735X pulls some serious amps under load. It points to the much more powerful motor in that unit. The power difference was clear during the planing operations as it didn’t seem to care what we ran through it. But it’s important to note if you’re going to buy the DEWALT DW735X you MUST have a dedicated 20A circuit as it’s not going to run well on a 15A circuit.

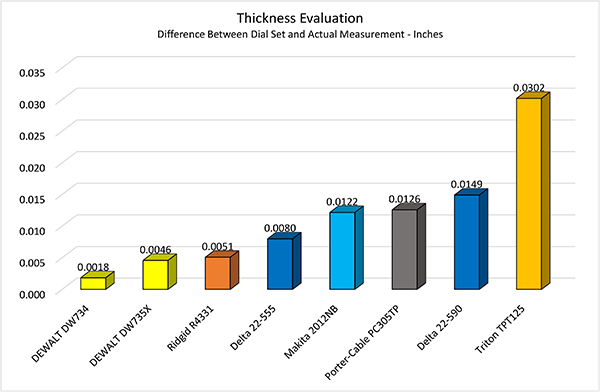

Depth of Cut Accuracy – Winner DEWALT DW734

Bench-top thickness planers have a dial used to move the cutting heads up and down to set the depth of cut. On each model the dial indicates how far the heads move up and down per revolution of the dial. We used calipers to measure the average thickness of each wood sample before and after a pass to remove 3/32″. We then compared how accurately each planer was able to do that and listed the average deviation from the 3/32″.

As you can see above, the DEWALT DW734 performed the best with an average deviation from 3/32″ of just under 2 one-thousandths of an inch. The DEWALT DW735X came in second with just over 4 one-thousandths of an inch followed by Ridgid R4331 at just over 5 one-thousandths of an inch. Last place was the Triton that averaged just over 3 hundredths of an inch deviation.

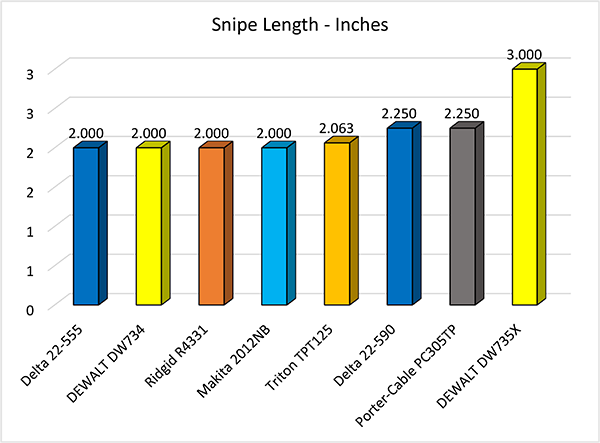

Snipe Evaluation

We tested how much material would be ‘lost’ to snipe. We had already adjusted each planer’s tables to be flat, and level to the planer bed, prior to the snipe test.

The TBB Crew selected the maple wood for the snipe test. We thought the lighter color and tight grain structure of maple might show the location and the depth of any snipes better than the other woods. For this test, we set all of the planers to a uniform depth of 3/32”. Each piece of wood was started at the first roller of the planer and we left our hands off the sample until it stopped past the outfeed roller. Next blue chalk powder was rubbed onto the last 6” of the board in order to make the snipe condition stand out visually. Finally we marked the ‘ridge’ of each snipe cut so that we could measure the amount of material that each planer produced for waste if the snipes were cut off to use the uniform thickness material.

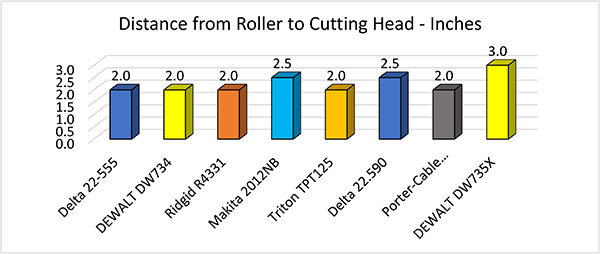

What’s interesting about this data is how well the snipe length correlates to the distance of the rollers inside the planers from the cutting heads. The length of snipe on all the models we tested nearly mimic this distance. The nice thing here is the snipe should be predictable for each model and allow users to plan accordingly. Users of the DEWALT DW735X will ultimately “waste” more material over the life of the planer. However, with all the planers having relatively the same amount of snipe we’re not ranking this category either but rather letting you see how they all compared.

Surface Finish Evaluation – Winner DEWALT DW735X

Another consideration when evaluating bench-top thickness planer performance is the surface finish. Bench-top thickness planers use a set of rotating blades to “shave” off the surface of the board being planed. As a result of the rotational blade movement, “small bite size” chunks are removed as each blade contacts the surface, resulting in very slight ridges that can be left on the surface of the planed board (often referred to as milling marks).

Planers can also tear out small chunks (scallops) from the surface. Between the milling marks and scallops the board could require more or less sanding to create a finished surface that will take paint, stain or clear finish well.

We applied blue chalk to the surface to highlight the milling marks, and scallops, for a visual inspection. We also evaluated the smoothness by simply feeling the surfaces. While very subjective, we ranked the planers based on the samples of Maple shown below.

While all the planers produced a “smooth” finish to the touch, there was quite a variation of smoothness resulting from the milling marks and scallops. The DEWALT DW735X was by far the best finish of all the samples we planed. The amplitude of the milling marks was consistently smaller and there was very little “scalloping” of the surface compared to all the other planers. This is likely attributed to the powerful motor and excellent blades. In addition, the 735 has three blades in the cutter head. Coming in 2nd place was the Triton TPT125 followed by the Ridgid R4331 in third place. Both the Triton and Ridgid had similar results. Coming in 4th was the Delta 22-590 with minimal milling marks but noticeably more scalloping.

Blade Change Evaluation

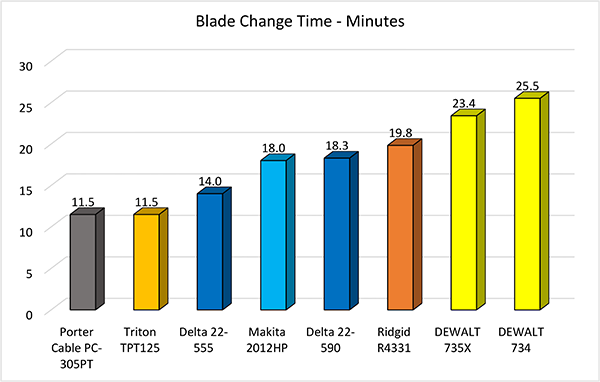

Is it easy or difficult to change out the blades on any given machine? Our crew took each machine and armed with the instructions and the tools in our workshop changed out each blade on each machine. Obviously, the planers with three blades would take more time than the machines with two blades. But is this process easier on some machines that others?

As you can see above the times required to change the blades on the planers varied from just over 11 minutes to just over 25 minutes. The reality is a user might change blades once or twice a year (twice would be heavy use) so the difference from 11 to 25 doesn’t seem enough to warrant why you might buy one over another model. Therefore we’re not going to rank this category, simply share the data so you can see that blade changes are not overly complicated.

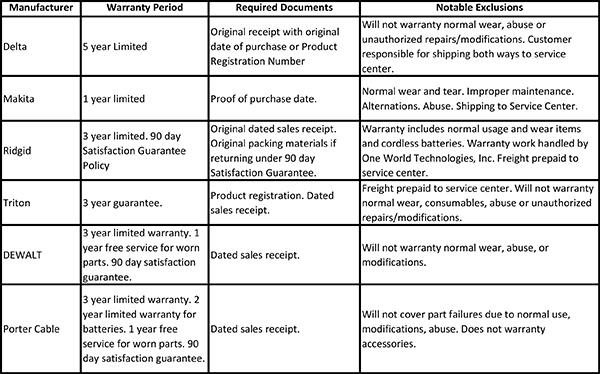

Warranty

Warranties are really important to some users, and many of you have asked us to include them in our reviews. Below is a list of the warranties applicable to the planers we tested. While ranking the warranties might seem simple, we’ve decided to just list them rather than rank them. Ultimately, warranties can be a tough issue, and how easily you can get warranty service is likely to be as important as how many years the coverage is. We’ll let you make your own determination on which warranty appeals to you.

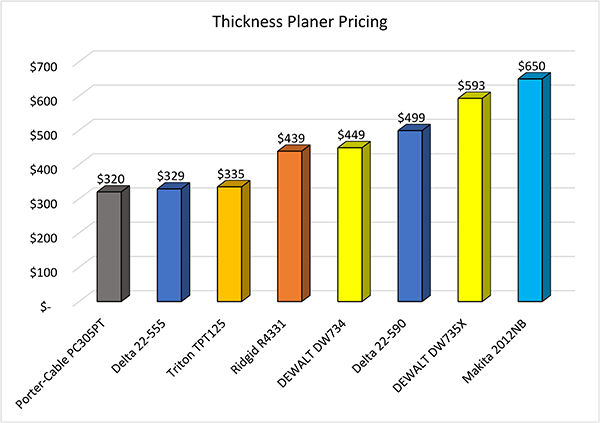

Price Evaluation – Winner Porter-Cable PC305PT

Price is often a huge part of the equation when determining what tool is best for you. There’s a huge difference in pricing in this test from the low $300 range up over $600. We are ranking these straight on the lowest to highest with prices available at the time of publication. We realize there is a “value” proposition that many will look at, but that will factor into our overall ranking when price and the other categories are combined. Finishing with the best price is the Porter-Cable PC305PT at $320 and rounding up the most expensive is the Makita 2012NB at $650.

Overall Winner, Best Benchtop Thickness Planer – DEWALT DW735X

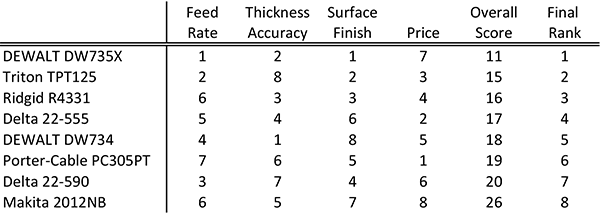

Here we are again trying to rank the tools in our Head-to-Head and give you a winner. The more of these we do, the more we learn, and in this evaluation we’ve taken a slightly different approach. Some of the categories that we set out to evaluate we decided not to include in the final ranking. However, we did provide information from that category as we feel it’s valuable to some readers.

Also, the more we do these the more some folks comment about how they would weigh different categories differently. That’s all great feedback, ultimately we need to come up with a winner (our winner) but each of you can take the data we’ve presented and weigh the results differently to best match your needs and come up with your own winner.

Below is a table showing how each of the 8 planers stacked up in the 4 categories that we counted in our final evaluation. Finishing in first place by a large margin was the DEWALT DW735X. This wasn’t a surprise to us as several of us have used this planer for quite some time and it’s really the best benchtop thickness planer on the market without a doubt. What did surprise us was the 2nd and 3rd place finishes of the Triton TPT125 and the Ridgid R4331. If you’re looking for a good performing affordable planer the Triton is certainly worth noting. Ridgid has a nice line of woodshop tools that go unnoticed often and it was nice to see them perform so well in this category.

While the Delta 22-590 finished near the end in this evaluation, the team felt it was also a nice planer to consider. The Makita is a very well-built planer with some nice features but the price wasn’t as competitive and the surface finish, at least on the materials we tested, wasn’t nearly as good as some of the other models.

Buy Now

Best Benchtop Thickness Planers – Head-to-Head Video Review

About the author

83 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Ihave a problem with my DeWalt 735. When the temperature is below 70 degrees and is getting colder the boards will not feede into the planner. It is like the feed rollers become to stiff. Suggestions – Please..

When was the last time you cleaned them? They really need to be cleaned off occasionally, I use mineral spirits.

I just watched a YouTube video on the DeWalt 734 planer. That video claims in the manual that the gap you saw in the out feed table to the mid table is supposed to be that way. It’s intended to keep pressure of the board to the rollers and reduce snipe. You might check to see if that’s correct as it’s likely true for the 735x as well.

Hit the rollers with a heat gun for a few minutes and wax the planer bed.

I watched this video on YouTube.

VERY nicely done.

A lot of good information, succinctly presented.

The movement between the speaker and showing the actual testing made for an interesting video.

Now I know better which tool to wish for!

Thanks Steve

Would be interested on how the planner below would rank in your test

King Canada KC-13HPC 13″ Planer with Helical Cutter Head

$699.99

Amazon.ca

I watch your channel and read your articles religiously. I find them to be entertaining and informative. As a DeWalt fan, I’m wanting to stay with that brand for my planer. I’m just a DIY guy and getting into a little woodworking for fun. By habit, I just always buy the best one on the market of what I’m shopping for. In my circumstance, where this is a hobby and I’m not churning out large amounts of wood here, will the benefits of the 735 be as pronounced over the 734?

Thanks TBB!

If you’re buying one to last many years then I’d say yes…just a big difference in performance. You get what you pay for 🙂

I have just looked at your planer review and I did not see any tests for cutterhead “paralleladigitty” or dust collection compatibility and performance. I have owned “portable” planers over my 40 years in the trade. Several 12-1/2″ Delta’s, easy portability. A P12(as I remember)Hitachi, the real deal! Two Ridgid’s, the current model returned when the warrantee repair center couldn’t understand that the cutterhead MUST be parallel. In addition, the earliest versions’ dust evacuation fan did not require any dust collector. The most current offering NEEDS a dust collector?! I still had my previous version which I have returned to.

One surface planer tip I use for accurate thickness pointer adjustment (another comparison point). Plane a 2′ board, cut off the snipe, cut into 4 pieces(3″+/-) and using a scale/caliper, a 3/4″ setting should yield 3″ stacked, exactly! Any minute difference will be magnified. My advice, you can run a 1×2 through on each side, at the same time, to truly see paralleladiggity to the platen. Further yet, run each side, one at a time and compare rigidity of the cutterhead and accuracy.

Curious if you found any significance of machine weight? Does a 92 lb planer perform better or worse than 58 lbs? Personal preference?

Interesting question. Weight may play into the performance but I’m not sure how we could “prove” that. Clearly the heavier machines have heavier parts, likely has less vibration resulting in a better user experience.

Hey Todd,

What a valuable guide on thickness planer. Excellent job!

I am about to purchase the DEWALT DW735X, as you mentioned. Thanks for helping a lot of people.

Can I ask what you think about the WEN units and why you chose not to review them? Are they not up to par with those tested or is there another reason? Thanks!

Edwin – Haven’t seen/tried them. We reach out to as many manufacturers as we can when we do these evaluations. Some choose to participate, some do not. Maybe one day we’ll do an update an include them.

Everywhere I look it shows the Ridgid R4331 as being a part of their lifetime warranty but your chart shows a 3-year limited warranty. Am I missing something? I’ve been going back and forth between the DW735X and the R4331 and knowing all Ridgid power tools have a lifetime warranty has been really appealing, especially when it covers batteries as well.

Sean – Have to look VERY closely at the RIDGID warranty website, different tools have different coverages.

I reached out to their support and clarified the warranty terms. It sounds like the 3-year limited is default but all you need to do to get the lifetime service agreement is to register the product on their website: https://www.ridgid.com/us/en/3-year-limited-warranty

Nice review. I just acquired a DW735 and am really pleased so far. However, I only run a few feet of pine through it. I had to unclog the discharge chute and rotate the blades. I already knew that the DW735 is a good machine, but you pointed out some features that make me more comfortable with my decision.

What are you running for dust collection? These need high volume dust collection to keep up with the massive amount of chips.

Hi Todd,

In my initial comments about my DW735, I failed to mention that I purchased as a used unit. The prior owner did not have a dust collector and he obviously had run some wood through it planing across the grain. This procedure throws out long fibers of wood rather than chips. The discharge chute was quite clogged when I first used it. Hence, I had to clean it out. To answer your question about my dust collector, I have a 1.5 HP JDS DustForce single stage dust collector and it handles the planer very well.

Again, thanks for a very good comparison of the different machines out there.

David W….

I was just wondering what your thoughts are on the Jet 13″ benchtop planer and how it would compare to Dewalts benchtop planer.

Haven’t tested it so I really can’t say.

Hey Todd great review. I’ve been looking to order either one of the dewalts or the makita. I have 20amp breakers in my shop and am wondering if that is enough juice to power either of those machines?

Joe – We ran them on 20 amp circuits. The real question will be do you have a separate dedicated circuit, because if you run this on the same circuit as your dust collection I’m certain that will be a problem. Good luck.

Hey Todd,

Between the Triton 125 and the Dewalt 734, what do you consider to be the better planer?

The DEWALT

Same Question, except Ridgid v. Dewalt 734

Tough….I’d say very similar.

Just curious, since the Triton rated higher than the Dewalt 734, why do you consider the Dewalt a better planer? I’m a newbie setting up my shop and I’m trying to stretch my dollars. The Triton is $100 less expensive so that is appealing.

Just has a better fit and finish. Could go either way I suppose.

Thanks!!

I appreciate the article, but “better fit and finish” is choosing “form over function”. Your own testing rated the Triton better. We are woodworkers, not shop decorators!

@Larry B – “fit and finish” is most certainly not choosing form over function. It’s everything about how well the components come together and the thoroughness of the attention the engineers and design team were to how the tool will be to use, take apart, snap together, the movement of levers, how much drift you get over time, etc. It’s everything after you get the tool home from looking at the specs, and then start to use it. I would argue fit and finish is huge, and it’s not something that shows up when looking at general specs.

can you comment on the softness of the Dewalt 735x blades, seems to have a problem holding an edge.

I’ve had great luck with them. I don’t use it daily, but I’m lucky if I change them once a year.

Will you add Cutech/Wahuda to the comparison tests?

We do not go back and add more tools. In several years we’ll likely do it again as new models roll out.

This article and corresponding Youtube video is amazing stuff! FYI the Triton link takes me to the blades, not the planer itself. Keep up the great work.

Nice review. I have the Dewalt DW734 and I’ve been pretty happy with it, except for one issue. The locking mechanism will not always hold, and frequently pops off while planing. I’ve noticed that the left side is loose (compared to the right side) and seems to be the cause of the issue. I can’t figure out ho to tighten it up. Have you seen this? And if so, do you know how to tighten it? Haven’t found anything in the manual or on the web.

I’ve never seen this happen unfortunately. Have you tried reaching out to customer service?

Excellent work. The 735x has two different feed speeds. Am I right that all of the testing that you presented used the faster feed rate so that you could compare apples to apples between the brands?

Did you test whether the planers, especially the 735x can actually handle the full widths they claim? Can you actually put 13″ work through the 735x without it bogging down or, put another way, how thick can the cut be at 13″ without bogging down too much? That would be an excellent test, especially since I think you were starting to see the effect of width with the poplar.

Ed – The test was performed on the higher speed. We didn’t try to max out width, but I can tell you from my own experience with the 735x that it does very well even on wider boards. With planers I always try to take small bites regardless of the wood species, and see how the planer reacts. At least for me I’m never in such a rush that an extra pass or two isn’t a deal killer for me.

Two things that I’d most like to see added to any future comparisons (of planers or any other tools) would be 1) some kind of likely longevity analysis, perhaps based on differences like plastic versus metal gears… and 2) the cost of replacement parts, especially those parts that are mostly likely to need to be replaced.

Eric – There’s just no way for us to realistically do that. Many guys ask us about that, but we’re not a testing company, we don’t have the tools, resources or time to do long term testing. What we do takes so much time as it is, no one pays us to do this, we do it with volunteers and samples. Wish we could offer more, but it’s just not feasible.

Hey Todd, is there anyone out there who has a good field set up for the 735X? Looking for an option that can be rolled out of a trailer and used on a stand reliably.

Jim – I’ve only seen guys store them in the trailer and carry them and set them on a work table at the job. While these are fairly heavy they are small enough to be pretty portable.

My neighbor has a roll around stand that works pretty well, still pretty heavy though

Jim, Dewalt makes a rolling stand for them. You can buy the X with it online,, just type in “with stand” in your Google search

Hey Jim & Todd,

Although I do not have the need to move my DW735x from one site to another, I have mounted it on a plywood rolling flip top cart which allows me to use either the planer or my Ridgid Oscillating Sander which are both housed in that same cart. Before building my flip top cart, I thought about purchasing a fold-up Ridgid miter saw cart. Their cart might work really well for Jim. It has 12″ wheels and can be easily set up and taken down by one person. I am not sure if the mounting holes on the DW735 will align with the mounting brackets of the cart, but that problem can be easily overcome…simply mount the planer to a properly sized piece of 1/2″ or 3/4″ plywood. Then mount the plywood to the cart’s brackets. I hope this might help. Todd, I am OK with your releasing my email address to Jim if he would like to ask any questions.

When you evaluated the price, it would have been nice if you had listed prices for replacement blades

Mark – That really wasn’t the point of the article. Like any tool, consumables are another topic all onto themselves.

Dewalt definitely has the thickness planner worth getting right now.

I don’t believe Makita should be that far down the list from its performance though.

great work. You have become my Consumer Report for woodworking tools. Just wondering if I would be paying a premium on the Dewalts because of who they are.

It’s just a better planer….worth the extra

Thank you for the time and effort put into this comparison. It is very well thought out and informative and provides me a good basis to compare between planers. I noticed that for the Triton planer, your picture differs from the stock photo (on/off switch, for example). I have searched and do not see any images online that represent the one you worked with. Do you happen to know if this is an updated version of the same model? If so, are the newer ones only sold by certain retailers? Thanks for your time.

Mike – Brands change minor items all the time, so I wouldn’t be surprised if there are slight variations.

Curious if the JET bench top planer was considered for the test. Do you have an opinion on the JET brand of portable planers?

We invited them to participate and they opted out. I can’t personally speak for it. I do have some JET tools in my woodshop and they are very nice.

excellent review ! there was some solid objectivity in evaluating the tool. Best of all, you provided us with the results so that we can decide what priorities to assess our purchase with.

Peter

Hi Todd,

I am always pleased with your comparisons, does not matter I am using those tools or not. It has a lot of information which can be used and helpful. But in this comparison, maybe I missed out something correct me then, you did not mention that DW735 has to speed gear and that is the reason for better finish of the surface. In my opinion you should test it on speed 1 which will be comparable with other brands. Also running on speed 2 will need more power (Amps) so this also should be taken in to consideration. I think speed 2 should be not used in testing procedure. Should be of course mentioned as a advantage of this unit, but not for overall comparison purposes.

Julian – Thanks for the nice compliment and for taking the time to post a comment. I personally don’t think speed 2 is an advantage, I think on speed 1 we would have seen even better results. Having two speeds is a great feature and worth noting. We’ll keep this in mind the next time we evaluate planers.

Great comparison review, and I appreciate you sharing the differences for categories that you did not include in the scoring, because it lets us add those back in to see what the revised score would have been if the category was ranked, or we can assign weighting to certain categories and see the ranking change considerably as well.

It’s too bad the Dewalt 735 requires so much juice. Even though I am lucky to have a 20A circuit, the dust collection would certainly be running on that circuit as well. In fact, my tool actually plugs into my Hilti dust collector (which I purchased based on your recommendation) to auto start/stop the dust collection.

That said, would you go with the 734 as your next recommendation, or move to another option? I ask because it seems that your personal recommendations do not necessarily align with the score rankings. I’m a hobbyist and would not be using this thing every day (or even necessarily every month), but I do like to buy tools that last and have good tolerances.

Luke – All of these planers definitely pull some amps at times and running them on the same circuit as a dust collector may be problematic regardless of which you choose.

Hi Todd, I was referring to your chart showing the ammeter readings:

https://www.toolboxbuzz.com/wp-content/uploads/2019/03/Planer-Amp-Readings.png

It would seem that based on that chart the DeWalt 735X is in a league of its own in terms of current draw, and would be far more likely to overload a dust collector that turns on/off based on the tool that is plugged into it. My Hilt shows it’s a 9A vacuum rated at 20A with a tool, which gives 11A to a tool before exceeding the 20A capacity.

Your chart was difficult to understand because it showed some of the tools going far beyond a 15 or 20 number on the y-axis. Were those amps on the y-axis?

In any event, it would seem that if one of these tools kept under 11A, it would work for a dust collect similar to mine, and if it did not then automatic dust collection could not work through a dust collector’s plug, which is an important consideration for a tool that produces a lot of wood dust.

I was confused by that chart, too, and wondered whether the amps aren’t “real” amps. In other words, motor loads can introduce currents out of phase with the voltage. I wanted to look up how circuit breakers trip- whether they only sense the real part, the full reactive current, etc. It’s not my area of expertise. Maybe someone can explain it here.

I wish I knew. Something seems wrong with that chart because the load does not seem to align in anyway with the rating of the device and would cause it to trip any 20A circuit. Hopefully the author can chime in with more insight.

Luke, I’m a hobbyist on the threshold of making it (furniture building) a job. My suggestion is two-fold. Hobbyists working in their homes need good dust collection more than anyone else. So, number one, research what you need for appropriate dust collection (a shop vac is almost certainly not adequate and won’t be getting the fines), hire an electrician, and run the circuit you need for the dust collection. If you can’t afford it, compare it to the cost of wood for a project or the cost of the planer. Then consider you are protecting your health and home. With that out of the way, comes #2. I have spectacular results with the Dewalt 735. You need a bunch of passes compared to a stationary planer, but that is true for all of the lunch box planers. With the Dewalt, though, I am getting snipe-free surfaces that take a quick pass with a handplane (or card scraper or sander…take your pick). It is completely different from sanding out the surface left by a typical stationary planer. Oh, and I don’t usually use the fine setting on the Dewalt. My only complaint is that the blades nick easily, but even so, I’m happy with the machine. Wear hearing protection. It is loud. It is basically a huge router on its side and sounds like one….but louder.

@me, I think that is sound advice. My concerns are less about justifying the cost of a dust collection system, and more about practical use of space. I cannot install a centralized dust collection system with my setup. My space is multi-functional and has to be setup each time to work. My Hilti VC-150XE will have to do as the dust collection for now. It’s intended for commercial concrete environments with very fine dust, so it should be good.

It would have been great to see the amp rating of each device listed. I could not interpret the ammeter results because the y-axis numbers did not appear to be amps, as the numbers far exceeded the 15A rating of each tool.

Luke, my situation is similar. Be aware that there is a difference between a vacuum with filtration to capture fines and one that moves enough air to collect them from the tool. In my case, I installed a 20A 240V circuit and purchased a Gyro Air G700 as it fit in a small space. It was expensive, though. You’ll need to evaluate the details to determine whether it meets your needs. If you go that route, be aware that they run sales several times per year. It looks like they are offering a sale right now. I’m not affiliated with them. One thing about this collector: The impeller is at the inlet, ahead of any cyclone, so make sure never to use it as a floor collector or in other situations where I might suck up chunks rather than dust. I may be overly cautious. I use this with my Dewalt 735 (to tie to the discussion here) and a 14″ bandsaw. In my experience with the 735, it generally works fine as the only tool on a 20A circuit, but it will occasionally trip the CB. That’s without a shop vac or other additional load on the branch.

Best comparison I’ve seen for these planers. I am seeking a planer and since it will end up in an off-grid location powered by solar and generator for long jobs, the power requirements are important. The graph on amperage draw for the different feed material is very interesting. It appears that all these units are equipped with 15 Amp, 110/120V single phase motors and the graph clearly indicates that some of them are going into high over load, particularly the DW735 at continuous 213% for the time it was dealing with the poplar. Most motors are designed for Service Factor 1 or 1.15 so this degree of overload could lead to overheat issues down the road. The power draw at this time was 32AX115VX0.85PF=3128W or 4.2HP. The Triton doing the same task 16AX115X0.85PF= half the power and also for 2/3 of the Dewalt time for less draw down on a battery system. Question – were all depth of cut settings for each machine the same for each specified material (was each machine doing an equivalent amount of work) . Also note the rising Amp draw on the RIGID with presumable constant load on the last piece of wood – motor getting warm?

David – If my memory serves me correctly, we set each planer to it’s maximum recommended cutting depth. So it’s possible some were cutting a deeper cut than others.

Thanks Todd – then the Dewalt was taking a deeper cut but by amp trace probably could have been reduced to reduce degree of OL. I noticed that Dewalt makes no differentiation in setup between hardwood and softwood

Certainly could reduce that amp draw with a thinner cut, but in that test we were purposely putting all the planers on a high demand application by taking the thickest cut they recommend. That planer is a beast and always feels more powerful than other similar planers.

David, thanks for your insight. You seem to have some electrical engineering knowledge. Do you have any idea how the DeWalt could actually operate at that load without tripping a 20A 120V circuit? It seems to me that maybe something was off with the measurement instrument.

Luke,

Despite our best efforts to measure accurate test data it’s likely a result of how we set up our test rig with the FLUKE ammeter. What’s important in the data is the relative measurements. More specifically, all of us with experience with the DEWALT (i have that model in my shop) know it simply won’t run well on a 15 am circuit, it will trip that circuit. I haven’t ever tripped it on a dedicated 20 amp circuit. It’s likely the #12 wire we used for the current tranformer probe, that probably should have been a #10 wire. Anyway, hope this helps.

Hey Luke I think Todd answered your OL question below. To me the amp trace says to reduce the cut depth a bit to bring the amp loads down, particularly if you do experience an overload. High amp overload and heat are not good for electric motors.

I want and can afford the DeWalt 635, but the weight issue for me is huge!!! At 92 pounds, it is not reasonable for me to take it off a shelf and sling it up onto a workbench height surface. That means a dedicated cart for it, and that means giving up a signif bit of floorspace in a crowded shop, for a machine that gets very occasional use. I appreciate you guys noting that weight issue. BTW, I have decided not to get the DeWalt. “You can;t always get what you want…”

Weight and size are always an important factor in small shops. I use the DEWALT in my shop and love it, mostly because finishing is EASY after planing with it, the surfaces are so nice.

Hello!

First of all thanks for the great video and article.

I have a question for what model you’d advice for me. Sadly here in Europe the DeWalt 735 is not available. Which leaves me to decide between the 734, the Triton and the not tested Metabo DH 330.

Thanks in advance!

Greetings from The Netherlands

Ben – The Triton is a solid unit! I’d definitely head in that direction. Good luck.

Todd, I know you have rated the Makita at the bottom but it does claim one unique quality: an 83dB noise rating, quieter than any other planer. That could be a significant factor to someone working oujt of their garage with neighbors nearby. Did you find this to be true in your tests?

Stan – We didn’t measure the noise as all of them are loud enough that ear protection should be used. You bring up a great point and one worth consideration if noise is an issue for neighbors!