Best 9 Inch Cordless Cut-Off Saw

Battery Powered 9 Inch Cut-Off Saw – Head-To-Head Test

An abrasive saw, or cut-off saw, is a circular saw which is typically used to cut metal and masonry. The cutting action is performed by an abrasive disc, similar to a thin grinding wheel. Technically speaking this is not a saw, as it does not use regularly shaped edges (teeth) for cutting. In this Head-To-Head we determine 9-inch cordless cut off saw.

9 Inch Cordless Cut-Off Saws

In 2015 Stihl was the first company to introduce a 9-inch cordless cut-off saw. Husqvarna was the second. Both of these saws are 36 volts and have a reputation for impressive run-times but were sorely lacking in power.

Then in 2018 DEWALT introduced the 60V FlexVolt which we reviewed last winter, and have been using on our job sites. Last to market was the Milwaukee in the Fall of 2019.

You might be asking why would you want a 9 inch cut-off saw?

It’s a fair question. The TBB Crew feels that these saws are NOT entry-level tools, but more of an expansion tool for users already on the platform. We refer to them as “80% Tools,” meaning they will do 80% of the tasks a gas tool will do.

Cordless cut-off saws enjoy a great range of applications and “niche wins.” Some examples are; mechanical contractors who use it for fast, super straight cuts in 8” PVC pipe, masonry and foundation contractors like it for the basement drains and “first-pass” door entry cuts. [occupied spaces] And let’s not forget the call back cuts or punch list applications once space is occupied.

Advantages of a 9 Inch Cordless Cut-off Saw

- Fast Ramp Up

- No Gas

- No Fumes

- Less Noise and Vibration

- Lighter and easier to use overhead

The fast ramp up on a cordless saw means that you can still get the power needed for cutting and Go After It!

9 Inch Cordless Cut-Off Saw Lineup

In order to keep the tools in this Head-to-Head somewhat similar, each manufacturer was asked to provide their most powerful battery. The following cordless cut-off saws were included in the test:

- DEWALT

- Husqvarna

- Milwaukee

- Stihl declined to participate

Cut-Off Saw Specifications and Features

DEWALT FLEXVOLT® 60V 9 Inch Cut-Off Saw DCS690B

- Cut depth: 3-1/4″

- Blade Diameter 9″

- RPM: 6,600

- Blade Arbor 7/8 in.

- Onboard Water Connection: Quick Connect

- Load Indicator Light

- Onboard tool storage

- Blade brake

- Tool Tag Ready

- Rotatable Guard – 5 Position

- 60v battery platform

- Tool Length (w/ battery): 26″

- Tool Weight (w/ battery): 10.85 lbs

Milwaukee M18 FUEL™ 9” Cut-Off Saw MODEL 2786-20

- Cut Depth: 3- 1/2”

- Blade Diameter: 9”

- RPM: 6,600

- Blade Arbor: 7/8”

- Onboard Water Connection: Quick Connect

- Load Indicator Light

- Onboard Tool Storage: For wrench and hex key

- RAPIDSTOP™ Blade Brake

- ONE-KEY™ Enabled: Yes

- Rotatable tool guard – Variable

- 18-volt battery platform

- Tool Length (w/ battery): 25.98”

- Tool Weight Bare Tool: 10.6 lbs Tool w/ 12.0 Battery: 14 lbs

Husquvarna 9 Inch Cut-Off Saw K 535I

- Cut depth: 3″

- Blade Diameter 9″

- RPM: 5,940

- Blade Arbor 7/8 in.

- Onboard Water Connection: Quick Connect

- Load Indicator – No

- Onboard tool storage – NO

- Blade brake

- Tool Tag Ready – NO

- Rotatable Guard – NO

- 36v battery platform

- Tool Length: 22.2″

- Tool Weight (w/ battery): 7.7 lb.

Best 9 Inch Cordless Cut-Off Saw – Factors Considered

The challenge for any Head-to-Head test is developing the testing and evaluation criteria in order to create a valuable comparison for users. There are hundreds of tests that could be performed, however with limited time and resources for this article we chose tests that we feel give a good baseline comparison.

For this evaluation the tests we selected to give a good relative, measurable comparison of run-time and the speed of cutting. We feel these tests will give you a good baseline on overall tool performance. Clearly run-time is hugely important with high demand cordless tools, and productivity is always an important benefit to consider when buying a cut-off tool.

9 Inch Cordless Cut-Off Saw Comparison Testing

- Full Depth 3″ Granite block cutting for run-time evaluation

- Rebar cutting for power and speed

- Multiple metals and masonry cuts in various materials for ergonomic review

- Cutting of concrete blocks and bricks

Cut-Off Testing Materials

Several test simulations were used which are considered typical of tasks where a contractor might use a 9-inch cordless cut-off saw for, these simulations include:

- Cutting concrete block [CMU]

- Cutting solid concrete block – this block has a very consistent matrix and is made in large precast batches.

- Cutting #5 rebar

- Gang cutting 5 pieces of #5 rebar

- Full-depth cuts in 3″ granite paver slabs

- ¼” thick steel channel stock cuts

Cut-Off Saw Testing Categories

In addition to the simulations, each of the crew members spent time cutting varying materials, to evaluate the cut-off saws independently. Our testing simulations and these individual evaluations were used to determine the Best 9 Inch Cut-Off Saw in several categories including:

- Size and Weight

- Features

- Performance

- Ergonomics

- Price

- Best in Class – derived from the above categories

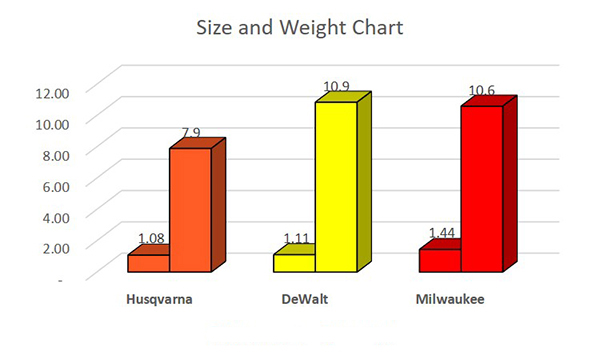

Size and Weight

WINNER – HUSQVARNA

The length, width, and height of the cut-off saws were used to determine their cubic volume, and rank was assigned based on volume and tool weight. In the accompanying graph, the left column is the size ranking of the saw and the right column is the weight of the saw.

The Husqvarna is noticeably smaller and lighter than the other two. Its battery placement is the dead center of the tool and between the users’ hands, making a well-balanced tool.

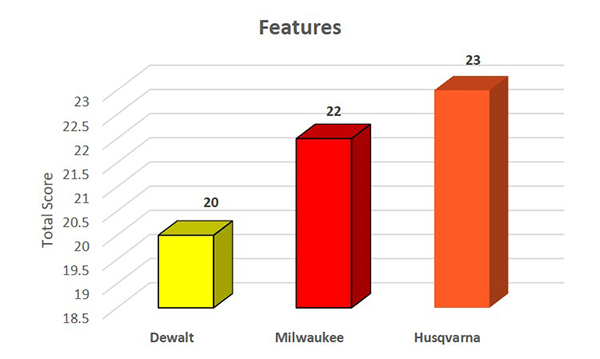

9 Inch Cordless Cut-Off Saw – Best Features

WINNER – DEWALT

The team felt that DEWALT beat out the Milwaukee and Husqvarna by two and three points respectively. DEWALT excelled in the disc guard, water feed, base plate, and battery compartment design.

Milwaukee excelled in their heavy load indicator and tool management [One-Key]. They took the number 2 slot in every other category. Husqvarna excels in their safety switch, water valve location and lanyard hook. They came in a solid second place in tool management [SavE function] and their shoe plate design.

For each “feature” category, the team ranked the tools 1, 2 or 3, (1 being the best).

| FEATURES | Dewalt | Milwaukee | Husqvarna |

|---|---|---|---|

| Disc Guard | 1 | 2 | 3 |

| Tool Management | 3 | 1 | 2 |

| On Board Wrench | 1 | 2 | 3 |

| Water Feed | 1 | 2 | 3 |

| Heavy Load Indicator | 2 | 1 | 3 |

| Shoe Plate | 1 | 3 | 2 |

| Safety Switch | 3 | 2 | 1 |

| Water Valve | 3 | 2 | 1 |

| Lanyard Ready | 2 | 2 | 1 |

| Battery Compartment | 1 | 2 | 3 |

| Spindle Lock | 2 | 3 | 1 |

| Total Score | 20 | 22 | 23 |

Stand Out Features

It’s one thing to tell you we rated the features and throw a number at it. It’s another to explain the differences and give you the detailed information. Below we break down the specific stand-out features on these saws.

Cutting Disc Disc Guard

All three tools have three different disc guard designs, they are:

- DEWALT – 5 positions, lock in position.

- Husqvarna – fixed.

- Milwaukee – fully adjustable, friction slide.

Both DEWALT and Milwaukee cut off saws have adjustable guards that offer the exact same range of adjustment. The difference is in how the guard is adjusted. The Husqvarna guard is fixed, you get what you get!

The DEWALT uses a 5-position system that allows users to move in position and lock it. Their belief is that this design is best for avoiding future problems. They designed their guard with this motto in mind:

“Living with the tool past a year or two!”

The Milwaukee has a friction glide and allows you to adjust the guard without having to be limited to pre-set detents. Many gas tools have friction adjustments and all work great when new for the 1st year. The problem is that crud and grit get inside the guard and freeze it up – it gets stuck! Let’s face it, no one cleans the guard until its frozen.

Tool Management

DEWALT has a tool tag accessory you can purchase and attach to their saw. Husqvarna has a feature on their keypad called the SavE. This feature decreases the blade speed [not power] and gives the longest run-time. Milwaukee is the only tool that offered true built-in tool management. They accomplished this with their One-Key system which provides the three options:

- Allows users to track tools that are lost or stolen

- Allows users to lockout the tool from unauthorized users

- Inventory management included in the app

Onboard Storage Wrench

Removing discs is easy on all three tools. The DEWALT stores its onboard wrench in the battery compartment. This wrench should never get lost! The DEWALT has a spindle lock that you hold in with one hand to lock the driveshaft, allowing the user access to the disc arbor nut.

The Husqvarna wrench is excellent but is not stored on the tool. Husqvarna has the easiest push-button, spindle lock of all three saws. The button has a rubber boot to protect it from slurry and water spray.

Milwaukee stores two tools at the rear of the tool; a wrench and an Allen wrench. The Allen wrench indexes into a hole to lock the shaft, freeing your hand up, and allowing the user access to the disc arbor nut.

The team felt that while Husqvarna has the best spindle lock and a 1-wrench system, not having onboard storage was a massive drawback. The DEWALT 1-wrench system onboard storage and spindle lock approach was simpler than Milwaukee’s two wrench approach. They also felt that was much less of a chance of losing the wrench given it is stored inside a latched battery compartment.

The nice thing about the Milwaukee is that once the Allen wrench is indexed, you can let go of the wrench – freeing one hand. The DEWALT arbor lock needs to stay depressed, if you let go of the arbor lock and move the blade slightly it will disengage.

Water feed

All three saws have water feeds on both sides of the saw – some companies offer only one side.

The DEWALT tool was designed with an enclosed Polyether-Class hose system. Polyether-class hoses are resistant to degradation, UV-resistant, durable, have good anti-aging properties and low-temperature-resistant properties. The DEWALT hose is also inside the tool until it transitions out of the tool at the guard handle. This encasing and shrouding protect the hose from snags and damage over time.

The Husqvarna water hose is made out of PVC Flex and tucks away nicely into a grooved channel, but the team felt that this hose is susceptible to snagging and damage.

The Milwaukee hose is exposed inside a small channel and secured with one clamp. Milwaukee uses PVC reinforced Nitrile Butadiene Rubber hose, designed for a long-life. The team felt that this hose could also be prone to snagging and damage. History and use have proven with gas model saws that have exposed hoses, over time they get hung up in metal and masonry – snag and rip off.

The DEWALT hose is visually smaller than the other two tools. One thing that we noticed is that DEWALT uses an internal stainless-steel spring inside the water hose as it travels up and over the saw to feed the other side of the disc. The spring results in a consistent hose radius.

Milwaukee’s hose was kinked in this location. The Husqvarna and Milwaukee both use a larger water hose. The DEWALT hose nipple is stainless steel, Husqvarna is made out of brass and polymer and the and Milwaukee uses Nickel-Plated Aluminum. None of the saws suffered from water flow issues and the larger diameter Husqvarna, and Milwaukee hoses probably have a larger flow than the smaller DEWALT hose with the inserted spring.

Heavy Load Indicator

DEWALT and Milwaukee have a heavy load indicator. This light tells the user that the tool is working hard, which will reduce battery life. Heavy load indicator light provides the user with real-time power and run-time feedback during demanding applications. If you want or need power it’s OK to keep pushing the tool “Go get it!” If you need additional run-time – back off.

Husqvarna has an indicator that will advise you when risking overloading or overheating the tool, and when the tool needs servicing. When seeing this indicator light both DEWALT and Milwaukee say backing off cutting pressure will increase run-time.

Milwaukee says pushing harder does NOT get you more with their tool. DEWALT says go get it and push if you need the power, but you’ll sacrifice on run-time.

We were able to stall all three saws by applying too much pressure. When pressing too hard, you can actually hear the saws struggle, indicating the need to back off slightly. This was something a user quickly gets used to and adjusts accordingly. On the DEWALT cut-off saw the light is either ON or OFF. Milwaukee says that the sweet spot is to get the light to flicker…. The perfect top-end of cut pressure/speed. They equate a flickering light to “Pushing to the edge of the cliff w/out overloading it.” [practice this to find sweet spot]

Milwaukee says when cutting rebar, you should “listen to the light,” and with concrete: pick a style and go!! [stay with it]

Drive System – Direct Drive vs Belt Driven

The folks at DEWALT say their shaft drive system is “Legit!” It’s a shaft drive system with a Lovejoy coupling. It is more efficient than a belt and helps minimize vibration. Because it is a shaft drive it will not slip and does not need regular maintenance unlike a belt that requires tensioning and replacement. DEWALT feels that their drive shaft is better than a belt-driven tool, resulting in no maintenance or slippage.

Husqvarna and Milwaukee both use a belt drive system and we noticed that the belt-driven saws result in slightly less cutting vibration. The Husqvarna and Milwaukee cut-off saws are smoother to run.

The Milwaukee vibrates at well under half of the vibration from the DEWALT. The Milwaukee has vibrations readings at 1.8 m/s² and the Husqvarna at 2.1 m/s². All three of these tools vibrate 3 times less than an orbital sander, making them very smooth to operate and not imparting much vibration to the user. In contrast, an electrical demolition hammer is around 18-22 m/s^2.

Tool Designs

All three saws have a similar design and size. The measurement from spindle to the rear handle set is the same as the popular gas models. On its simplest level, user experience [UX] is how you feel about every interaction you have with the tool in front of you, at the moment you’re using it. UX is a lot more than that; ranging from concept to research, engineering, prototyping, testing, and user testing, to list a few.

These tools were clearly designed to give users the same feel as a gas tool. Users are conditioned to the gas feel and these tools mimic that experience

Handles

All three tools featuring a front handle that can be held in three positions can be used to cut in both horizontal and vertical positions.

The DEWALT front rubberized handle looks a lot like the non-rubberized Husqvarna. It is comfortable, and the handle does an excellent job of providing comfort in overhead use applications. The Dewalt front handle has a few indented places to rest a thumb when holding horizontal. We felt that these indexes were not great and would be hit or miss depending on the user.

The Husqvarna handle has more hand room than the other three, allowing for easy winter-gloved operation. The handle is has a smaller diameter, a nice gradual curve and is comfortable to use. The handles slight-slope to the side, was no doubt designed to user support hand, wrist and elbow comfort. It allows for many hand positions and does an excellent job of providing comfort in overhead use applications.

The Milwaukee cut off tool has a thick rubber rear handle, and a much a thinner, smooth plastic front handle. The handle design is straight across and allows more room for a gloved user. Comfort and securing the tool in the hands was the GOAL for these tool companies and they clearly approached their designs differently.

Base Shoe

DEWALT’s base shoe is wider than one would think it needs to be. The team felt that this shoe provided an excellent pivot point for plunge cutting. Husqvarna provides both a wide metal shoe plate with two rubber feet to keep the tool from sliding. The Milwaukee shoe plate is half the width.

The tools with the wider shoes result in the tool cutting straight and also helps with perpendicular plunge cutting. The team felt that the wider DEWALT and Husqvarna bases provide more protection, better pivoting and provided better stability side to side.

Safety Switch

The DEWALT has a manual push-button on/off switch, once activated the tool trigger is live. The Husqvarna has an on / off keypad switch that will time-out with 1 minute of non-use. While this is outstanding as a safety feature, the team often picked up the tool to use it and were annoyed that they had to turn the saw back on repeatedly. The Husqvarna rear handle also has a “power trigger lockout safety switch”, similar to their chainsaws. Milwaukee uses a dual-trigger, which encompasses a small trigger safety- spring flap on the main trigger. The spring-loaded flap that needs to be depressed before activating the trigger.

Water Feed Valve

The DEWALT has a T-handle valve knob that is very easy to operate. The ease to operate also equated to valve slop – meaning that the knob had a lot of side-to-side play. Husqvarna separated their valve knob from the water nipple by placing t higher on the tool – a much easier location to reach and activate. The Milwaukee uses a half t-style knob, we found it is stiff more secure and durable.

All three tools [dual-sided water delivery system] achieve OSHA Table 1 Compliant solution for dust management when cutting concrete and masonry materials.

Tool Head Style – Maneuverability

Left to Right [close] all three tools are small enough, and designed for a solid angle cut approach. With a fresh masonry blade attached, the DEWALT is capable of a 3-3/8” deep cut, the Husqvarna a 3″ cut and the Milwaukee a 3-1/2” deep cut.

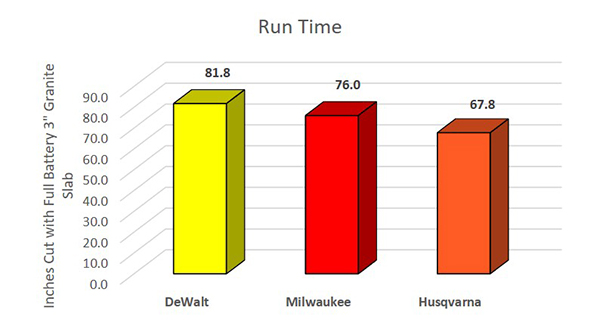

9 Inch Cut Off Saw – Run-time Testing

WINNER – DEWALT

Which 9 Inch Cordless Cut Off Saw had the most run-time? We used several large 3″ thick slabs of granite scraps, fully charged batteries, and the same brand diamond blade for this test. After scribing lines on the granite, we had the same operators cut the slices of granite using the water cooling systems on the saws. We were careful not to push the saws too hard and monitored the load indicators to ensure that we did not use excessive pressure.

We continued to cut until the tool could no longer cut the granite. It was interesting to note that both DEWALT and Milwaukee [with the enclosed battery compartments] had thermal overloads activate before the batteries were exhausted. We allowed the hot batteries to cool and continued to cut until the battery registered no power. The Husqvarna battery is not enclosed in a compartment, so it did not have a thermal issue.

The DEWALT saw cut 3″ thick solid granite for a distance of 6’9-3/4″ on a single battery charge. The Milwaukee was able to cut 6’-4” and the Husqvarna 5’-7 3/4”.

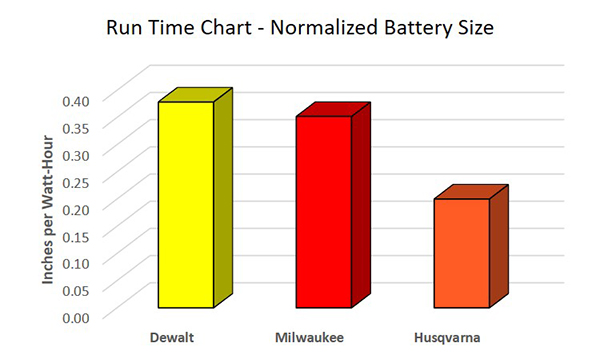

Granite Cuts Per Watt-Hour

One interesting aspect of the run-time test came to light when the TBB Crew looked at the capacity of the batteries in the three cut-off saws. The DEWALT and Milwaukee saws have a 12.0 amp-hr battery. The Husqvarna has a 9.4 amp-hr battery. By using watt-hour (total battery pack energy) we level the field for both voltage and amp-hours.

Watt-Hours is calculated by multiplying the voltage (actual voltage, not the MAX that some companies advertise) by the battery pack Amp-Hours. This calculation allows us to compare the total energy available to do the work based on both the voltage and size of the battery pack (amp-hours).

The Husqvarna comes with a smaller amp-hour battery than the DEWALT or the Milwaukee (9.4 vs.12 amp-hr). However, the Husqvarna is a 36-volt battery. This means that the total watt-hr. for the Husqvarna is 338 vs. 216 watt-hr. for the other two saws. However, despite the size differential in watt-hr, the results look the same for the regular runtime test as for the normalized-runtime test. The DEWALT and Milwaukee saws are newer and the results of the normalized data show us that these two saws are more efficient than the Husqvarna.

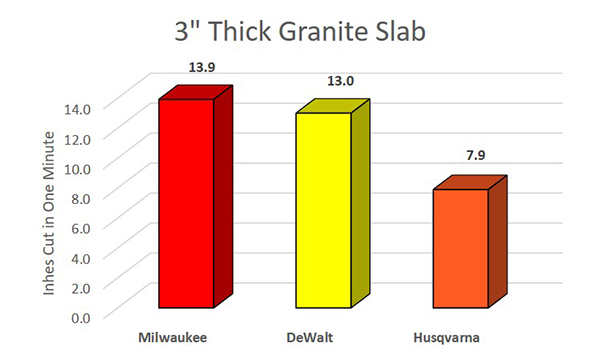

9 Inch Cut-Off Saw – Performance (Speed) Testing

WINNER – MILWAUKEE

We performed a speed test in the 3″ granite to see which saw was capable of cutting the most granite in one minute. The operator pushed each saw to the point where the overload light came on, or rpm decreased, then backed off the pressure to operate in the tool’s performance “sweet spot.” The test was timed and stopped after one minute of cutting. The distance cut was measured at the bottom of the saw blade kerf. The Milwaukee cut slightly faster than the DEWALT and almost twice as fast as the Husqvarna.

What a great system to cut masonry and concrete with a tool that’s fully compatible with my BRAND batteries ~ JEFF [TBBCrew]

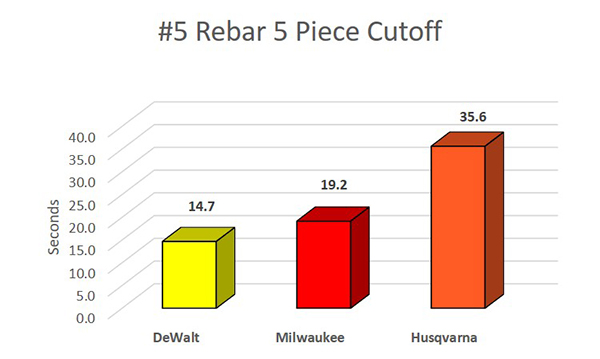

Steel Cut-Off Performance (Speed)

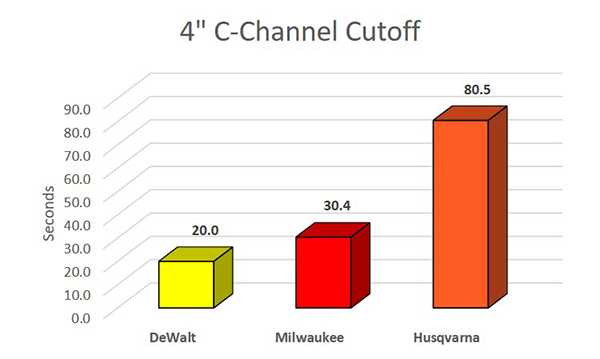

WINNER – DEWALT

The performance of the three saws were evaluated cutting steel. We put the saws through their paces by cutting five “ganged-together” set of #5 pieces of rebar. In addition, we cut through a piece of structural steel C-Channel. The TBB crew kept the saws spinning at, or near, they’re “sweet spots” for performance by modulating the pressure on the saws.

The DEWALT was the fastest cutting at 14.7 seconds followed Milwaukee 5-seconds after and third was the Husqvarna at 35.6 seconds.

- DEWALT was 14.7 sec

- Milwaukee was 19.2 – about 33% longer

- Husqvarna was 35.6 – 2.4 X the DEWALT time

In both of these steel cutting tests, the DEWALT saw really outperformed the other two saws, as can be seen in the following two graphs.

In the 4” C-Channel steel cutting test, the DEWALT was the fastest saw, at 20 seconds, cutting almost twice as fast as the Milwaukee and four-times faster than the Husqvarna. The Milwaukee saw cut at 30.4 seconds and the Husqvarna at 80.5 seconds.

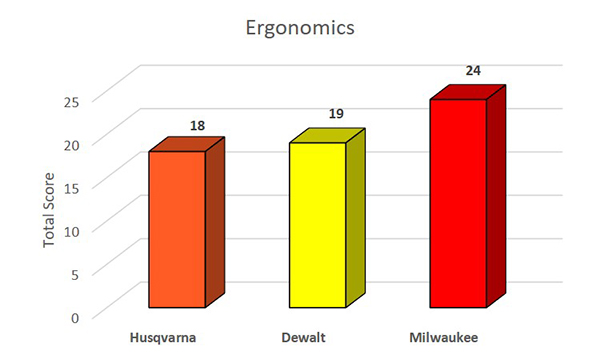

9 Inch Cut-Off Saw – Ergonomics Evaluation

WINNER – HUSQVARNA

Ergonomics play a major role in all of our evaluations and 9-inch cordless cut off saw testing. Not only does a tool need to perform well, but it’s very important that tools are comfortable, which ultimately leads to more productivity and reduced risk of injury.

50% lighter than gas saws and with no gas headaches ~ ETHAN [TBBCrew]

For the ergonomics evaluation, the team evaluated the following: grip, handle, blade guard, disc change, power switch, battery change, vibration, balance, and maneuverability. For each category, the team ranked them 1, 2 or 3, (1 being the best). Much of the ergonomics evaluation came from team members using the cut off saws. Each team member used each tool, cutting different materials to get a relative comparison of each tool.

For the ergonomics evaluation, the team evaluated the following: grip, handle, blade guard, disc change, power switch, battery change, vibration, balance, and maneuverability. For each category, the team ranked them 1, 2 or 3, (1 being the best). Much of the ergonomics evaluation came from team members using the cut off saws. Each team member used each tool, cutting different materials to get a relative comparison of each tool.

| ERGONOMICS | Husqvarna | Dewalt | Milwaukee |

|---|---|---|---|

| Grip | 2 | 1 | 1 |

| Front Handle | 1 | 1 | 2 |

| Guard | 3 | 1 | 2 |

| Disc Chg. | 1 | 2 | 3 |

| Switch | 3 | 1 | 2 |

| Batt Chg | 1 | 2 | 3 |

| Vibration | 1 | 3 | 2 |

| Balance | 1 | 3 | 2 |

| Manueverability | 1 | 2 | 3 |

| Sight Lines | 1 | 2 | 2 |

| Onboard Tool Storage | 3 | 1 | 2 |

| Total Scores | 18 | 19 | 24 |

The Husqvarna beat the DEWALT by one-point and the Milwaukee by six points. The Husqvarna excelled in almost every category but lost points due to its fixed disc guard, multiple switch operation, and lack of onboard storage. Overall the team felt that the Husqvarna was the nicest, smoothest operating saw tested.

The saw starts with a squeeze of the trigger instead of repeated pulling on a cord and eliminates the need to mix gas and oil or maintain a gas engine, gotta love that! ~ STAN [TBBCrew]

Both DEWALT and Milwaukee saws came out after the Husqvarna giving them time to improve their design. The DEWALT came in one point behind excelling on improvements to the grip, guard, and trigger switch. The Milwaukee excelled in grip and was consistently number two in almost every category except blade change and maneuverability.

9 Inch Cut-Off Saw Best Price

WINNER – DEWALT

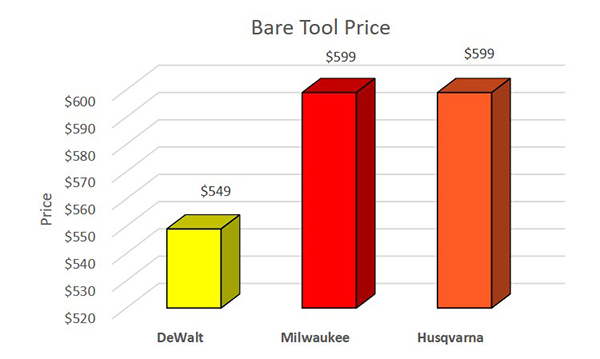

Pricing is a key part of the purchasing mix, and it’s crucial that you get it right in order to determine the Best 9-inch cordless cut off saw. For this Head-to-Head we looked at bare-tool pricing to eliminate discrepancies in the composition of the kits provided by different manufacturers.

When you look at the bare tool pricing the DEWALT is lower than the competitors and a competitive kit price. Keep in mind that we tested the DEWALT kit with 12Ah batteries but at the time of publication the DEWALT kit comes with 9.0Ah batteries and the Milwaukee kit comes with 12Ah batteries which definitely adds value.

Below is a graph showing the pricing (at the time of publication) of each tool:

- DEWALT $549.00

- Husqvarna $599.99

- Milwaukee $599.00

The DEWALT is $50.00 less than the Milwaukee and while a $50.00 difference is not a big spread, the bigger story may be purchasing this tool as an expansion to your current DEWALT or Milwaukee battery platform.

Less noise, less vibe, no maintenance and great for overhead work, that’s a win! ~ ROB [TBBCrew]

Buy Now From Our Sponsored Retailers

Ohio Power Tool

Best 9 Inch Cordless Cut-Off Saw Winner

WINNER – DEWALT

As usual, the Head-to-Head competition was very close but at the end of the Day the Tool Box Buzz Crew must pick a winner and the DEWALT is our winner of Best 9 inch cordless cut-off saw.

The Best 9-Inch Cordless Cut-off saw is the DEWALT Flexvolt DCS690B. This saw looks feels and performs like a pro-grade tool. It was pretty obvious during our testing that the DEWALT was a powerful cutter, and the results showed that. The DEWALT saw took first place in five categories, and second place in two categories for a total of 8-points. The first place categories were; features, runtime, [2] metal cutting speed tests and the bare tool price evaluation.

The Milwaukee came in second, with 12-points. The Milwaukee took first place in the granite speed test, third place in ergonomics and second place in every other category. It is a powerful, fast, and solid performing saw. Following up in third place, with 16-points, was the Husqvarna, which took first place in ergonomics, second in price and third place in all other categories. The Husqvarna has been out a lot longer than the other two tools and has not benefited from a “Gen 2” upgrade. If they do – watch out!!

| Best Saw Results | DeWalt | Milwaukee | Husqvarna |

|---|---|---|---|

| Features | 1 | 2 | 3 |

| Ergonomics | 2 | 3 | 1 |

| Run Time Granite | 1 | 2 | 3 |

| Speed Test Granite | 2 | 1 | 3 |

| Speed Test Rebar | 1 | 2 | 3 |

| Speed Test C Channel | 1 | 2 | 3 |

| Price | 1 | 2 | 2 |

| Totals | 8 | 12 | 16 |

Final Thoughts

So why would you want a 9 inch cordless cut-off saw? The simplest answer is that these saws are an extremely versatile solution for cutting a large variety of materials, these tools harness cordless technology to deliver the power to cut metal and masonry materials without using gas like most traditional cut off saws. That’s a win in our book!

Milwaukee M18 Cordless Switch Tank – Water Supply

When cutting masonry and concrete, most users turn to a water supply with a hand pump or even another worker with a bucket dumping water. The Milwaukee M18 SWITCH TANK™ provides a 4-Gallon Backpack Water Supply to be an OSHA® Table 1 Compliant solution. This water supply delivers instant, constant, and adjustable pressure up to 60 PSI and operates off Milwaukee’s M18 batteries.

M18™ SWITCH TANK™ 4-Gallon Backpack Water Supply (2820-21WS)

• Dual Diaphragm Pump

• Pressure: 20-60 PSI (5 Mode Adjustable)

• Flow Rate: 0.16 – 1.13 GPM

• Run-Time: Up to 12 Tanks per Charge

• Seals: Nitrile

• Hose Length: 10’ w/ Quick Connect

• Nozzles Included: Water Spray Nozzle

• Weight: 18.45 lbs (M18™ Powered Base, Tank Assembly & M18™ XC3.0 Battery)

Who has the BEST 9 Inch Cut-Off Saw – Video Review

About the author

2 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Damn, those are awesome. I generally pride myself on my creativity in justifying tool purchases, but as an industrial electrician I can’t seem to come up with a need for The Flexvolt cut off saw. Want one pretty bad, though lol

I know… I occasionally need to cut pavers and random bits of metal. The problem is that the flexvolt grinder is so powerful, I just put on a 7″ blade and go to town! Now I need the 9″ cutoff and the switch tank…