DEWALT FLEXVOLT™ 12 Inch 120V Miter Saw Review

FLEXVOLT™ 12 Inch 120V Dual Bevel Compound Miter Saw DHS790AT2

FLEXVOLT 120V 12" Miter Saw

DHS790AT2 Features & Specifications

- Flexible power options – corded or cordless – this saw can run off battery power and AC corded power.

- Accuracy cutline blade positioning system and highly visible miter and bevel scales

- Portability – Compact design weighs only 56lbs.

- 12 inch diameter blade

- 1 inch arbor

- Max cut thickness 6-3/4″

- Max Degree Miter Left and Right: left 50 Right 60 degrees

Variable Power Options – AC and DC Power

The first and most important feature of this saw has been the ability to use it as a cordless saw when we had no power, to eventually switching over to running it plugged into the AC power source. The DHS790AT2 is designed to run off (2) FLEXVOLT 60V battery packs, or you can run it on AC power by simply installing the convertor that plugs into the battery pack sockets. Because the saw is running on 120V from the battery, the conversion to run off 120V AC is fairly simple to do (we REALLY wish they would do the same thing on the FLEXVOLT Table Saw!).

This option makes the new FLEXVOLT miter saw one of the most versatile cordless tools we’ve ever used. Having this type of option available to high demand tools like a miter saw allows users the maximum amount of flexibility to get the job done using one tool.

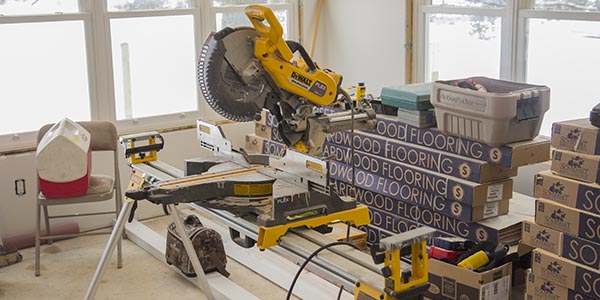

Job Site Performance – FLEXVOLT Miter Saw

In order to get a real grasp on the overall performance of the new DEWALT FLEXVOLT 12″ Sliding Miter Saw we’ve spent over 6 months evaluating the saw on both new construction and remodeling projects. My crew has been using the saw since August on a new house build on a lake here in NH. We started using the saw for the beginning stages of framing the house walkout basement when there was no power on site yet, and we used the saw all the way to the finish stages when power was available in the house.

What stands out most about this miter saw is how well it performs in both cordless and corded modes. There is no noticeable difference in performance from one mode to the other, and the saw performs just as we’d expect from experience using our other 12″ DEWALT miter saws over the years.

While framing the walkout basement on this project, the crew was able to cut framing lumber all day using just two battery packs (two are required to run this saw). The batteries were plugged in during lunch break to give them an additional 30 minutes of charge time, but I’m not even sure that was needed. The saw has plenty of power for cutting framing materials including engineered lumber, even when running in the cordless mode.

Precision and Accuracy

We found the DHS790AT2 to be very accurate right out of the box. No adjustments were needed for the miter or bevel factory settings which was a nice surprise. After six months of use we continue to be impressed with the saws accuracy and precision even though we use it for both rough framing and finish work. We’ve used the saw cutting exterior trim, decking, interior oak stair treads, and interior trim with great success. Again, I’d compare this saw to any of the DEWALT saws we’ve been using on the job for years.

Packed with Features

The DHS790AT2 is packed with all the features that you’d expect from a quality miter saw. Our favorite feature is the cutline blade positioning system (shadow line) that DEWALT has been offering for quite some time. We like this system much better than older laser systems because it accurately reflects the width of the blade being used. The miter controls and detents work flawlessly and are easily adjusted if need be. Lastly, the blade guard that DEWALT uses is one of the best in my opinion. It works smoothly and never gets hung up like some of the other guards on the market.

Run Time

We found run time for this new saw to be really good. In a run time test we performed last summer we were able to cross cut 124 times in a SPF 2×12. This test was performed using (2) 60V 6.0 Ah FLEXVOLT battery packs. The test involves cross cutting (at 90 degrees) the 2×12 every 10 seconds for a total of 10 cuts. Then the saw is allowed to rest for 1 minute. Then another 10 cuts are made, followed by another rest. We feel this is the best way to simulate actual use on the job. Obviously, with the new 9.0 Ah battery packs that were just released this month, the run time will be even greater.

In job site use, we found the saw had plenty of run time to keep up with the crew throughout the day. If a crew had one extra set of batteries, they could work all day even under the most demanding applications.

Suggested Improvements

This saw is really good and doesn’t have much in the way of issues that we found to be noteworthy. I would like to see DEWALT explore options to allow for bevel adjustments near the front of the saw instead of having to reach around the saw to control the bevel settings. While that might seem like a minor issue, we think it’s an important design issue that makes a miter saw safer and much easier to use, especially if you make lots of bevel cuts.

A larger issue that we have discovered with the FLEXVOLT miter saw is an electrical interference issue. While doing finish work in the new house we’re building for a client we discovered an issue that we’re hoping DEWALT can resolve in the near future. When plugging the saw in using the AC adapter it is causing breakers to trip in the electrical panel of the house. What’s really strange is the fact that it’s not tripping the circuit that it’s directly plugged into, it’s tripping other dual function AFCI/GFCI breakers in the panel. This must be an issue with the converter and signals it’s sending through the electrical system. Needless to say it’s a nuisance that’s not fun to deal with, and one that customers are likely be be annoyed with when doing renovation and remodeling work. We’ve reached out to DEWALT hoping they can address the problem.

Update: We’ve been in contact with the design team at DEWALT and they are aware of the issue. They are working on identifying the issue and working on a possible solution. We’ll keep you posted as things develop. The tool was tested heavily for use with GFCI protection, but may not have been evaluated for recent developments and requirements for AFCI (Arc Fault) protection.

DEWALT FLEXVOLT Sliding Miter Saw Video Review

Overall Impression – DEWALT FLEXVOLT Sliding Miter Saw

The last year or so we’ve seen cordless miter saws of several sizes make their debut and the results have been very impressive. However, none of them have been a full size 12″ saw and none of them has the option to be plugged in directly to an AC power source as well as being cordless. That has all changed now with the introduction of DEWALT’s new 120V FLEXVOLT 12″ Sliding Compound Miter Saw.

The DHS790AT2 is the best full size miter saw for job site applications in our opinion. Offering all the features of DEWALT’s 12″ sliding compound miter saws with the option of running cordless it’s hard to compare it to any other miter saw on the market. Run time is excellent and the power it offers in the cordless mode doesn’t appear to be any different than when plugged in directly. With the recent availability of 9.0 Ah battery packs (we did our evaluation with 6.0 Ah packs), the saw will offer even great run time and versatility. We feel the $799 price is fair for a quality saw like this that offers such amazing flexibility for contractors.

One issue that must be considered however is the fact that users must upgrade to a new battery platform to run the FLEXVOLT miter saws. This saw only runs on the 60V battery packs and will not run on older 20V packs. For some users this will leave them feeling a bit left out from all the 20V packs they have invested in.

If you’re in the market for a full size job site miter saw then look no further. This is the saw you can put in the job trailer and use it in any situation and have no need for a generator. This would be a 5 star review except for the slight glitch we experienced with the electrical panel. Hopefully that gets resolved soon and this saw becomes the gold standard.

DEWALT FLEXVOLT 120V 12" Miter Saw

About the author

20 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

The 780 will trip arc breakers as will many power tools not just this saw. Any appliance can trip an arc fault breaker, even a loose neutral on another breaker could trip an arc fault.

Just to follow up if arc breakers are tripping and the appliance is not plugged into said breaker it is a wiring problem, maybe common neutrals etc… or older arc breakers where problematic.

Actually it’s not a wiring issue. DEWALT is working on the issue now. It has something to do with the brushless motor (something we don’t typically see in a plugged in tool), and the converter. None of the other power tools on site are tripping the breakers. We’ve got compressors, table saws, and even other miter saws running with zero problems. It’s actually tripping the dual function AFCI/GFCI breakers, and we’re not even plugged into that circuit.

I just bought this saw and found a potential issue. A full depth of cut the blade is rubbing on a small piece of plastic inside the channel. I haven’t run the saw at that depth but I know I’ll need to. Has anyone else run into this or know anything about it?

We haven’t had that issue to date.

I’ve had this issue too and I just got my saw yesterday.

With the Depth Stop lever deactivated so that the Lock Down pin can be used to lock or unlock the saw, the blade touches the plastic underneath the kerf plate when the blade is fully pulled down and pulled forward. It cuts the plastic into little black pieces even though the blade does rotate while sliding the saw back and forth. The saw is unplugged while doing. I can take photos.

Mine has been randomly losing its connection to the batteries. Not just the weaker ones that are being discharged from the work in progress, but even the freshly fully charged batteries also. Hmmmm? Wiggling the batteries and taking them in out doesn’t seem to help. Anyone have similar issues or a solution. I have been using my saw 14 months now.

Haven’t had this issue with ours. Do you have more than one set of batteries? Just curious if it’s a bad battery or something on the socket that connects them to the saw. How does it run with the adapter on it?

Does the 56lbs include the two batteries installed?

that’s the bare tool weight

Any update on FLEXVOLT miter saw is an electrical interference issue?

We haven’t heard anymore from DEWALT on the issue. They certainly were aware of it, we’re still using the older version so I’m not sure if it’s been fixed in newer models.

Any issues with flexwolt miter saw keep turning off? I have a saw for couple of days only. Finally it’s warm outside I have a saw on sun. Is it some overheating protection or …?

There is software built into them to shut down if they get too hot

I got my saw about 2 years ago. A couple of days ago I cutting 1×6 and it just stopped working. If you pull the trigger the light flashes but nothing happens. I’ve seen a few others with this issue, but no one has a answer

Not sure what is happening, best to see a service center.

Arc fault breakers are garbage. I won’t allow them to be installed on any job I do. Regular breakers and gfi’s have served us well for many decades and the arc faults are just another way to raise a revenue under the guise of health and safety. They are ten times the cost. They only thing they have proven is they are a danger if one has to continually go to the service panel and reset the breaker, and I have seen zero evidence that they have substantially saved anyone’s house from burning down or being electrocuted. The codes were set up to provide a minimum standard, not a continual moving standard under the guise of health and safety with the real reason of raising revenue. It’s not just the saw, it is a bunch of electrical equipment that is causing trips.

Jarrod – Don’t really disagree with you! However, they are required by law and we have to deal with it every day on jobsites. Not much we can do.

My flexvolt saw just caught fire and it doesn’t work with the cable or the batteries and I have a friend who had the same thing happen with his dewalt machine too, I don’t recommend it to anyone because I wasted my money and got rid of a miter saw a cable and I don’t regret it

Greetings! Has anyone encountered a failure with the Dewatl DHS790 Flexvolt Miter Saw(Gen 1) running the ac adapter heavily resulting in motor failure similar to what’s described by FinishCarpentryTV: https://youtu.be/4DwWrbFr7vg ?