Ridgid Tri-Stack 5 Gallon Compressor Review

RIDGID Tri-Stack 5-Gallon Portable Electric Compressor

Several months ago the folks at Ridgid sent me their new Tri-Stack 5 Gallon Compressor (Model OF50150TS) to test and review. Compressors are one of the power tools that my crew seems to destroy go through often so I was very interested to test this new compressor design.

From Ridgid

The RIDGID Tri-Stack 5-Gallon Portable Electric Steel Orange Air Compressor can be configured a variety of ways and has the versatility of 5 tools in 1. All tanks together provide maximum power, while tanks separated from the compressor are ideal for tire inflation or use at a distance with longer lengths of tubing. This compressor can even be set up for multiple tools with separate pressure requirements. The oil-free pump delivers reliable performance with less maintenance than traditional air compressors.

- Powerful induction motor for maximum power, durability and quick starts

- 150 psi maximum pressure

- Innovative steel tank design allows compressor to be configured for a wide range of tools, applications and environments

- Compressor and independently regulated tanks separate for easy carrying and versatile, simultaneous uses

- 1/4 turn tank drain, valve on each tank turns quickly and easily for convenient tank maintenance

- Oil-free, low-maintenance pump

- UL listed for safety and reliability

- 2 independent regulators control air pressure on both tanks for maximum utility

- Well balanced and equipped with a handle for portability to and from the work site

- 3 universal (air outlet) quick couplers accept 1/4 in. industrial- and automotive plugs with easy single-hand connection

- Includes the compressor only, air tools and accessories sold separately

- Air Delivery: 4.9 SCFM @ 90 PSI

Max PSI: 150 PSI

Tank Capacity: 5 Gallons

Pump Type: Oil Free

Quick Couplers: 3, Push to connect style

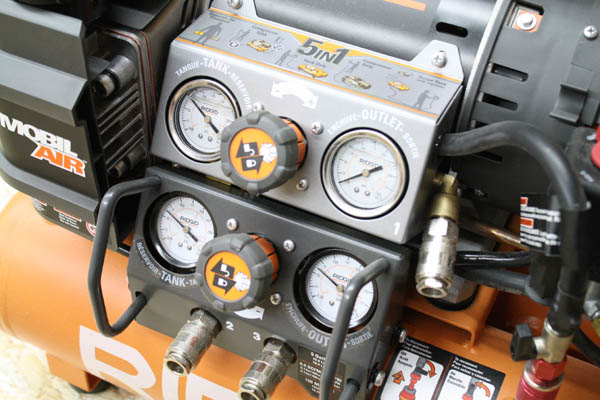

Gauges: 4, 2 in. diameter with metal housing

Regulator: Fully adjustable locking style

Motor: Induction Motor

My Thoughts On The Ridgid Tri-Stack

Portable compressors are a vital piece of equipment for all contractors. The biggest problem with them is the term “portable” as they are often anything but portable! Most compressors large enough to support house construction weigh in at over 80 lbs. They are usually difficult to carry and move in and out of trucks and job trailers. According to the folks at Ridgid this new Tri-Stack compressor tries to address that problem and make a system that’s more portable and versatile.

Weight and Portability

Ridgid has definitely addressed the portability issue with the unique design of the Tri-Stack. The motor/compressor portion of the unit can be quickly detached from the air tanks. This allows someone to either just carry half the load or carry a portion in one hand while the other hand carries the remaining portion. This makes for a much more balanced and comfortable carrying situation!

Weighing in at around 77 lbs the Tri-Stack is certainly heavy. But when you break it down into two pieces it becomes more in line with some of the average pancake compressors that are so easy to transport. Separating the two sections is as simple as rotating a locking hub and disconnecting the supply hose from the compressor to the tanks. I think the system is easy to use and very functional with regard to the separation procedure.

Power

The Tri-Stack has a maximum pressure of 150 psi. It can generate 4.9 SCFM @ 90 PSI which is a fairly respectable supply of air.

I tested the compressor in a number of different applications including framing guns, finish nailers and pressurized air for cleaning up shop dust. In each application the compressor supplied plenty of air pressure along with a good volume.

Versatility

The Ridgid Tri-Stack really shines in the versatility category. This compressor can be used in several configurations which allows it to be extremely versatile. The following are the configurations that I find quite useful.

- Complete System – With the compressor and tanks all connected this compressor offers three quick connects. One of them can be used at one pressure while the remaining pair can be used at a separate pressure. This is ideal in situations where maybe one person is framing with a high pressure while two others are using finish nailers at a lower pressure.

- Surge Tank – In this setup the compressor/motor would be running outside while an air hose is run from that unit to the air tanks located inside closer to the work. This is nice because it puts the noise and heat outside while keeping the tank near the work area. This is especially useful during trim projects like kitchen cabinet installations.

- Compressor Only – In this situation you’d bring the compressor/motor by itself to the work area with no tank capacity. This is great for really small tasks like punch list work. The only drawback is the motor has to be running the entire time because their is no storage tank.

- Air Tank Only – This would be perfect for a really small job like installing a couple pieces of small molding. If you needed to be quiet then you could pre-fill the tanks with air and carry only the tanks to the work area, use your tools and leave without making very much noise.

Short Video Review

Before sharing my final thoughts on the compressor I thought a short video review would be nice. Check out the video real quick.

Final Thoughts

The Ridgid Tri-Stack 5 Gallon Portable Compressor is a very versatile, capable job-site compressor. Overall I was very impressed with it’s quality, versatility and performance. I really like the easy to use design that allows you to separate the compressor motor from the storage tanks which greatly improves portability.

If I had one thing to pick on it would be the total weight. Weighing in at 77 lbs the compressor is still very heavy especially for one person. If this compressor could about 15 lbs less it would be a home run! However, don’t let this deter you as it’s still lighter than many of the 80+ lb compressors on the market.

If you’d like to buy one of these they can be found at The Home Depot or online at the following link:

About the author

10 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

I just this compressor and I already love it. The one think I noticed though was on the two gauges of the upper portion look like some of the oil in them has leaked out, do you have any idea what this is? I notice it is the same on yours.

The compressor came that way. I’ll check with the folks at Ridgid and see why they are that way.

Ok I spoke with Ridgid and here’s their response:

“The gauges on the upper manifold are oil filled gauges. The oil ensures the gauges stay calibrated by absorbing vibration from the pump, which is located on the upper half of the unit. ”

So yes it’s normal that only the upper gauges are oil filled.

Yup – The oil filled gauges dampen vibrations and keep the needle from bouncing back and forth so fast it’s unreadable. They tend to be more expensive to replace however are typically found on better quality units.

Thanks for the review.

Rigid tri-stack is one of the worst compressor I ever own, first one I own for almost three months got cylinder gasket busted, homedepot gave me a new one, same thing happened for around another three months. It’s heavy, and not even running on 15amp outlet like they said it does. Never buy another ridgid tool product beside plumbing tool.

I have had NOTHING but problems with my tristacks…. three compressors… three burnt out motors within a very short amount of time… used the first one on a generator, so ok… figured power source problem… last two have been directly hooked with the power cord to outlets, same result motors that burn up. Trying to get them serviced has been a nightmare as my Homedepot can’t seem to send me to anyone that actually works on them…. so I am doomed to exchange them.

I have to agree with the last 2 reviews…I loved the idea of this compressor but after a dozen or so uses it is done. It won’t bleed off the air after stopping so won’t start again without tripping a breaker. I put a wrench on the fitting to remove the controller from the tank and it broke off, then found the fitting below it had a crack in it. This was a huge waste of money…and no warranty help as it was past the year. Off to the recycle center it goes.

Problems with mine also…..

The bad part is that I did not cross the T’s and dot the I’s on my warranty, so pretty much my own dime. 🙁

One othe thing I haven’t heard anyone else mention is that it has got to be about the loudest compressor I have owned. If you want a radio on or hear other people this has to go outside – about 100′

Hi there

anyone can tell me this air compressor do they made for 220~240V

I’m live in Australia look to get one just because i in loves it.

and how much cost to ship to Australia.

Appreciate for your reply.

Rigdig compressor randomly stop giving me air I dont understand what happen