Best Cordless Impact Driver Head-To-Head | 2023

Best Cordless Impact Driver

There’s no doubt that Impact Drivers have completely changed the construction industry and drastically improved both productivity and quality. Impact drivers allow users to install screws, structural fasteners and small bolts more efficiently than a drill. Impact drivers drastically reduce broken fasteners, stripped screw heads and costly delays. An impact driver relies on a hammer and anvil mechanism to deploy rotational force when fastener resistance is encountered.

In our Best Cordless Impact Driver Head-To-Head test, we’ve selected 19 full-size impact drivers from a wide range of manufacturers. We invited all of the major manufacturers to participate, with some brands sending multiple impact drivers.

These impact drivers range from 18 to 40 volts. Traditionally, we would separate tools by voltage ranges, for example separating 18 volts from 24, 36, or 40 volts. We know that some may think the more voltage the better for the impact driver, but is it really? Well, we’ll find out soon enough.

Cordless Impact Driver Head-To-Head | Line Up

Fifteen manufacturers sent us their best cordless impact drivers. We received the following 19 impact drivers for this Head-To-Head.

BOSCH

- Model: GDX18V-1860CB25

- Voltage: 18v

- RPMs: 0-3,400 RPMs

- BPMs: 0-4,100 BPM

- IN-LBS Torque: 1,860 In-Lbs

- Weight: 2.6 Lbs

- Price: $99.00

DEWALT

- Model: DCF850B

- Voltage: 20v

- RPMs: 0-3,250 RPMs

- BPMs: 3,800 BPM

- IN-LBS Torque: 1,825 In-Lbs

- Weight: 2.1 Lbs

- Price: $149.00

FEIN

- Model: ASCD18-200 W4 Select

- Voltage: 18v

- RPMs: 0-1,500 RPMs

- BPMs: 0-3,000 BPMs

- IN-LBS Torque: 1,859 In-Lbs

- Weight: 2.20 Lbs

- Price: $308.00

Festool

- Model: TID18

- Voltage: 18v

- RPMs: 0-3,200 RPMs

- BPMs:

- IN-LBS Torque: 1,593 In-Lbs

- Weight: 2.12 Lbs

- Price: $ 219.00

FLEX

- X1371A-Z

- Voltage: 24v

- RPMs 0-4,000 RPMs

- BPMs: 0-4,450 BPM

- IN-LBS Torque: 2,500 In-Lbs

- Weight: 2.7 Lbs

- Price: $159.00

Hart

- Model: HPID26

- Voltage: 20v

- RPMs: 0-3.000 RPMs

- BPMs: 0-3,000 BPMs

- IN-LBS Torque: 2,200 In-Lbs

- Weight: 2.5

- Price: $77.86

Hilti

- Model: SID6-22

- Voltage: 22v

- RPMs: 0-3,600 RPMs

- BPMs: 0-4,250 BPMs

- IN-LBS Torque: 2,655 In-Lbs

- Weight: 2.2 Lbs

- Price: $199.00

Kobalt

- Model: KID 124B-03

- Voltage: 24v

- RPMs: 0-3,100 RPMs

- BPMs: 0-3,800 BPMs

- IN-LBS Torque: 2,000 In-Lbs

- Weight: 2.4 Lbs

- Price: $149.00 (Kit only)

Makita 18V

- XDT19

- Voltage: 18v

- RPMs: 0-2,700 RPM

- BPMs: 0-3,200 BPMs

- IN-LBS Torque: 1,330 In-Lbs

- Weight: 3.31 Lbs

- Price: $219.00

Makita 40V

- Model: GDT01Z

- Voltage: 40v

- RPMs: 0-3,700 RPMs

- BPMs: 0-4,400 BPMs

- IN-LBS Torque: 1,950 In-Lbs

- Weight: 2.76 Lbs

- Price: $217.00

Metabo 18v LTX

- Model: 602396520

- Voltage: 18v

- RPMs: 0-2,900 RPMs

- BPMs: 0-4,000 BPM

- IN-LBS Torque: 1,800 In-Lbs

- Weight: 2.1 Lbs

- Price: $179.99

Metabo 18V LT

- Model: 602397850

- Voltage: 18v

- RPMs: 0-3,050 RPMs

- BPMs: 0-3,750 BPM

- IN-LBS Torque: 2,400 In-Lbs

- Weight: 2.6 Lbs

- Price: $131.99

Metabo HPT 18V

- Model: WH18DBDL2C

- Voltage: 18v

- RPMs: 0-2,900 RPM

- BPMs: 0-4,000 BPM

- IN-LBS Torque: 1,832 In-Lbs

- Weight: 2.9 Lbs

- Price: $129.00

Metabo HPT 18V

- Model: WH18DC

- Voltage: 18v

- RPMs: 0-3,700 RPM

- BPMs: 0-4,000 BPM

- IN-LBS Torque: 1,859 In-Lbs

- Weight: 2.0 Lbs

- Price: $129.00

Metabo HPT 36V

- Model: WH36DBG

- Voltage: 36v

- RPMs: 0-2,900 RPM

- BPMs: 0-4,100 BPM

- IN-LBS Torque: 1,859 In-Lbs

- Weight: 4.1 Lbs

- Price: $189.00

Milwaukee

- Model: 2953-20

- Voltage: 18v

- RPMs: 0-3,900 RPMs

- BPMs: 0-4,400 BPMs

- IN-LBS Torque: 2,000 In-Lbs

- Weight: 2.24 Lbs

- Price: $149.00

Ridgid

- Model: R862312

- Voltage: 18v

- RPMs: 0-3,400 RPM

- BPMs: 0-4,300 BPM

- IN-LBS Torque: 2,400 In-Lbs

- Weight: 2.26 Lbs

- Price: $139.00

Ryobi

- Model: PSBID02B

- Voltage: 18v

- RPMs: 0-2,900 RPMs

- BPMs: 0-3,800 BPM

- IN-LBS Torque: 1,920 In-Lbs

- Weight: 2.55 Lbs

- Price: $119.00

Skil

- Model: ID6739B-40

- Voltage: 20v

- RPMs: 0-2,700 RPMs

- IPMs: 0-3,400 BPM

- IN-LBS Torque: 1,800 In-Lbs

- Weight: 2.47 Lbs

- Price: $69.99

Cordless Impact Driver Evaluation Criteria

For our Best Cordless Impact Driver Head-To-Head test we tried to develop tests that focus on productivity and performance that relate to PRO users in the field.

We did not consider run-time. We feel that most of the major tool brands that are offering full-size impact drivers are using good lithium-ion battery packs along with brushless motors. In most situations, these tools will run long enough for the average worker to complete his or her work in a workday. Furthermore, if the user owns two or more battery packs, it’s extremely unlikely they will drain one battery before the second one is charged and ready to work.

Cordless Impact Testing – 7 Scoring Criteria

We designed four performance tests across a range of applications, these four tests address driving speed, torque, and control. Additional scored categories included qualitative and quantitative evaluations. Lastly, we include but did not rank price and best value categories.

Scoring Criteria:

- Performance Test– measured speed to install 3-1/8″ Deck Screws

- Performance Test – measured speed to install structural screws using a hands-free jig

- Performance Test – measured speed and evaluated spin-out

- Applied Torque Test -Measured breaking torque capability under demand.

- Ergonomics -Ergonomics is really important to users and an important category to consider when purchasing any power tool.

- Features -An overall comparison of features and specifications.

- Size and Weight – size matters, in this case, we want a light and compact tool that can get to get the job done.

- Best Value – Often times this category winner tends to resonate with most folks as it tends to perform well in the tests and also feels good on the wallet. Not ranked.

- Price – Price is always an important factor in determining which driver is best for a user. We’ve included the current pricing found online for each of the drivers “as-tested,” at the time of publication. Not ranked.

Structural Screw Test | Winner Metabo HPT 36V

We installed #9 x 3-1/8″ GRK structural screws into 4″x6″ pressure-treated lumber. This is a task that we feel many of our readers do regularly and highlights a task that can benefit from improved speed and productivity.

NOTE -GRK screws are an industry-leading fastener that is used in all facets of construction applications. GRK screws feature a Climatek (corrosion-resistance) coating approved for use in exterior or treated lumber.

In this test, we pre-started all the screws at the same height. We installed five fasteners, recording the time to install each fastener. The average time was taken to determine a rank. The same user conducted this test for each impact driver and did not apply any force, or use a supporting hand.

The Metabo HPT 36v Triple Hammer was the winner of this performance test. It drove the five screws with an average time of 0.68 seconds per screw. Coming in with a three-way tie for second place was FLEX, Metabo HPT (WH18DC), and Milwaukee all at 0.73 seconds.

| Deck Screw Speed Test Results | |||||||

| MFG | Run 1 (s) | Run 2 (s) | Run 3 (s) | Run 4 (s) | Run 5 (s) | Average (s) | Ranking |

| Metabo HPT 36v | 0.86 | 0.65 | 0.63 | 0.68 | 0.60 | 0.68 | 1 |

| FLEX | 0.79 | 0.75 | 0.84 | 0.70 | 0.55 | 0.73 | 2 |

| Milwaukee | 0.75 | 0.78 | 0.75 | 0.61 | 0.74 | 0.73 | 2 |

| Metabo HPT 18DC | 0.73 | 0.86 | 0.65 | 0.71 | 0.71 | 0.73 | 2 |

| Makita 40v | 0.84 | 0.71 | 0.77 | 0.63 | 0.80 | 0.75 | 5 |

| DEWALT | 0.80 | 0.83 | 0.68 | 0.65 | 0.86 | 0.76 | 6 |

| Makita 18v | 0.75 | 0.73 | 0.70 | 1.01 | 0.90 | 0.82 | 7 |

| Ridgid | 0.86 | 0.80 | 0.75 | 0.83 | 0.86 | 0.82 | 7 |

| Ryobi | 0.80 | 0.80 | 0.85 | 0.80 | 0.88 | 0.83 | 9 |

| Skil | 0.93 | 0.85 | 0.80 | 0.81 | 0.76 | 0.83 | 9 |

| Metabo HPT 18DBD | 0.88 | 0.88 | 0.88 | 0.81 | 0.88 | 0.87 | 11 |

| Kobalt | 0.78 | 1.02 | 0.81 | 0.85 | 1.01 | 0.89 | 12 |

| Hart | 1.03 | 0.91 | 0.86 | 0.98 | 0.78 | 0.91 | 13 |

| Hilti | 1.06 | 1.00 | 1.00 | 0.86 | 0.88 | 0.96 | 14 |

| Bosch | 0.96 | 1.02 | 1.03 | 1.00 | 0.86 | 0.97 | 15 |

| Metabo 18LTX | 0.95 | 1.16 | 0.98 | 0.98 | 0.95 | 1.00 | 16 |

| Metabo 18 LT | 1.30 | 1.05 | 0.90 | 1.17 | 1.03 | 1.09 | 17 |

| Festool | 1.43 | 1.33 | 1.01 | 1.03 | 1.20 | 1.20 | 18 |

| FEIN | 1.63 | 1.37 | 1.68 | 1.33 | 1.43 | 1.49 | 19 |

Finishing in the back of the pack was the FEIN with an average score of 1.49 seconds. Still FAST!!

Structural Fastener Test | Removing Human Error

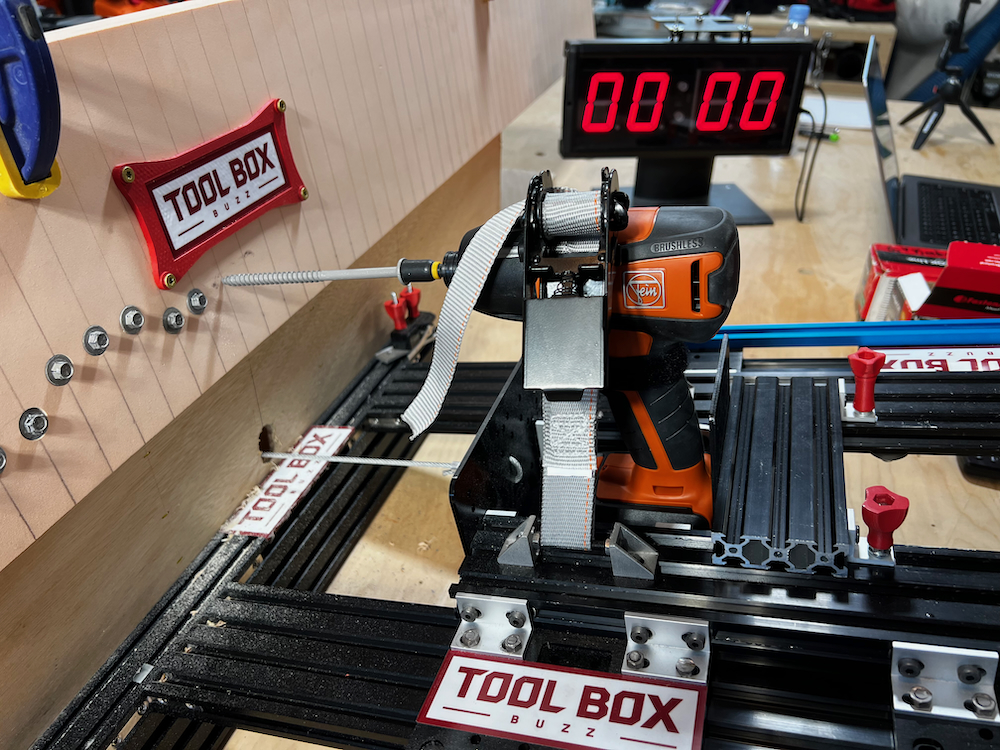

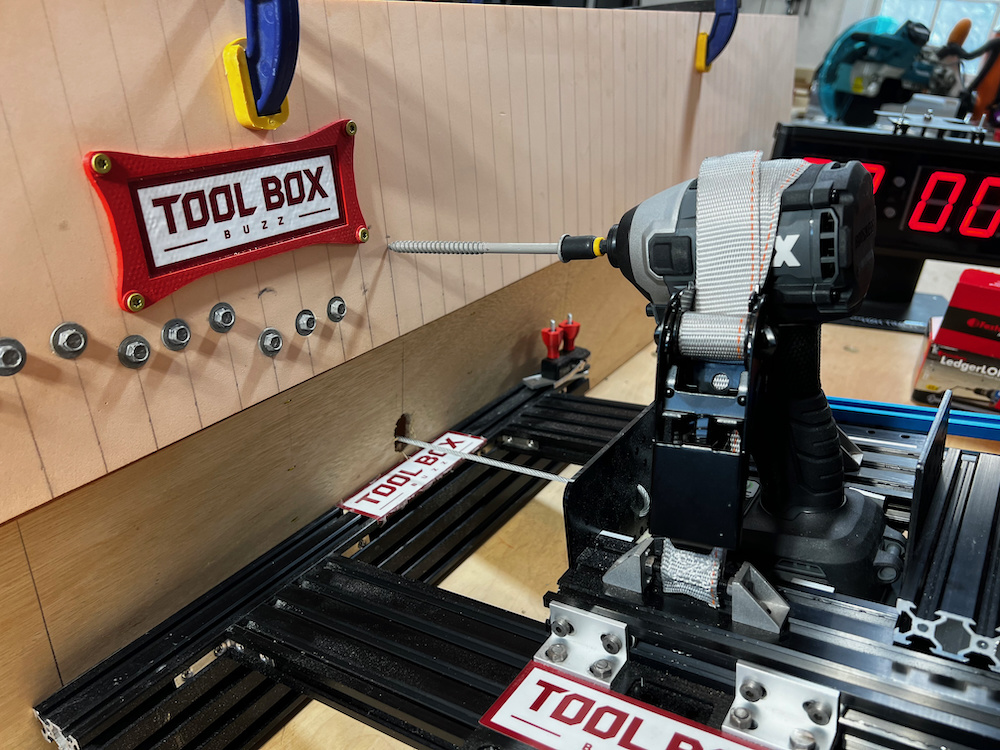

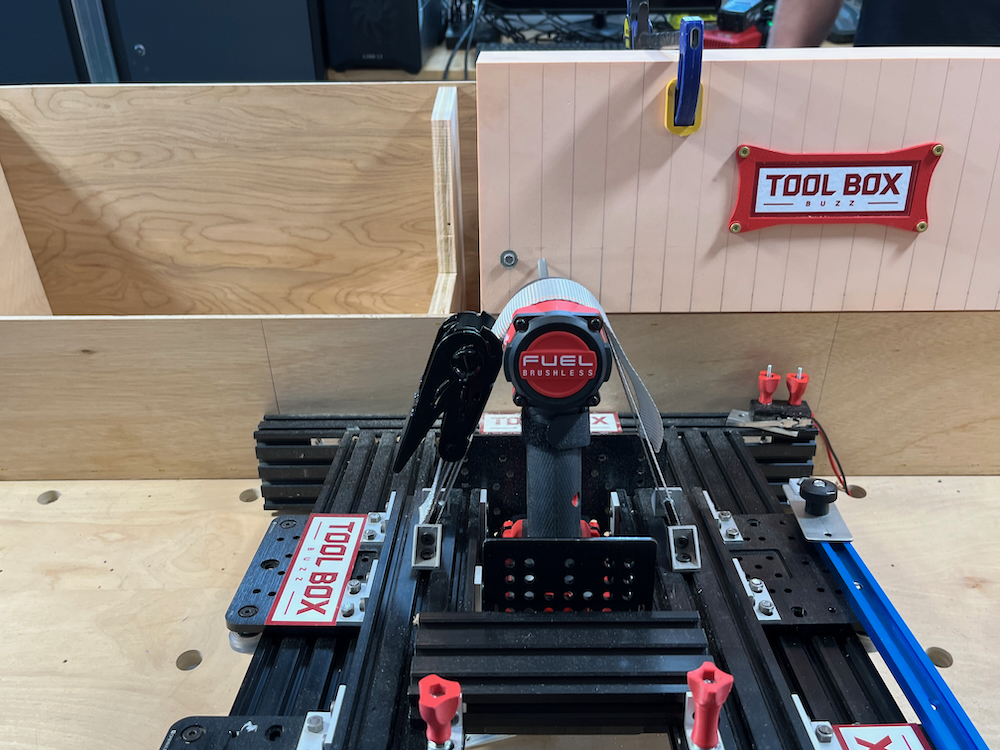

For the last several years Tool Box Buzz has tried to add at least one test in each Head-to-Head that took the human error out of the loop. While we pride ourselves on adding valuable subjective feedback in these tests we feel it is important to have at least one performance data point across all these tools that are without influence from the user. For this Head-to-Head, we designed a rig to hold the tools while it drove 5″ long TimberLOKs. In an effort to elevate this test to the next level, we added something new and unique to our testing, Obomodulan or Polyurethane boards.

Obomodulan is a cast Polyurethane board that is used for model construction, tool making, and mold production. We wanted to find a material that we could use to replace wood, but would still behave like wood without the inconsistencies of knots, gaps, and varying densities. These boards can be cut, milled, drilled, and even sanded like wood. For this test, we used Obomodulan 502 which has a density of 29 lbs/ft³, which is right in the higher range of white pine.

To put the naysayers at ease, we conducted a series of tests driving fasteners into both KD wood and structural foam. The timed results were comparable between the two, with the interesting factor that the wood had inconsistent result times due to knots, splits, and different densities. The foam provided consistent and precise results for each impact driver.

Impact Testing Rig

To test structural screw performance, we built a jig to hold the impact drivers. We used this jig to remove as much human variation as possible to allow for the fairest test possible. In prior tests, we used a cable and pulley system to provide a consistent force in a single direction. When using a saw or a drill we tune this force to equal that of a skilled operator. With impact drivers, the advancement of the tool is determined by the rotational speed of the fastener. We added a cable and pulley system to this rig to provide just enough force to keep the impact and its bit securely in place on the fastener as it advanced into the material.

The sled fixture held the impact drivers securely and in the same plane as the fastener, while the aluminum tracks kept the driver moving in a consistent and parallel fashion. All the impact drivers were set to their highest setting.

During the course of testing, the fixture operated with no issues. Two strategically placed micro switches to regulate the start and stop times of the fastener insertion. The micro-switch timing starts as soon as the fastener insertion is initiated and just after the fastener passes through the last of the material. Removing the human error element of a handheld stopwatch.

Structural Fastener Test | Winner FLEX

Individual tools had very consistent times during their three runs. The tools completed this 5″ TimberLOK test with times ranging from 3 to 12 seconds. The field was very tight, with the top 12 impacts completing the task within 3 to 5 seconds on average time.

The FLEX scored first with an average time of 3.05 seconds. Coming in second place was Milwaukee at 3.22 seconds, followed by RIDGID with an average time of 3.66 seconds.

| Structural Fastener - Hands Free Rig Results | |||||

| MFG | Run 1 (s) | Run 2 (s) | Run 3 (s) | Average (s) | Rank |

| FLEX | 3.07 | 3.06 | 3.02 | 3.05 | 1 |

| Milwaukee | 3.26 | 3.27 | 3.12 | 3.22 | 2 |

| Ridgid | 3.57 | 3.81 | 3.61 | 3.66 | 3 |

| Metabo HPT 36v | 4.25 | 4.22 | 4.37 | 4.28 | 4 |

| Metabo HPT 18DBD | 4.61 | 4.31 | 4.15 | 4.36 | 5 |

| Metabo 18 LT | 4.32 | 4.34 | 4.48 | 4.38 | 6 |

| Metabo HPT 18DC | 4.87 | 4.36 | 4.26 | 4.50 | 7 |

| DEWALT | 4.61 | 4.41 | 4.5 | 4.51 | 8 |

| Kobalt | 4.61 | 4.68 | 4.59 | 4.63 | 9 |

| Makita 40v | 4.73 | 4.62 | 4.58 | 4.64 | 10 |

| Hart | 4.93 | 4.88 | 4.61 | 4.81 | 11 |

| Hilti | 5.70 | 4.72 | 4.51 | 4.98 | 12 |

| Makita 18v | 5.18 | 5.04 | 4.97 | 5.06 | 13 |

| Ryobi | 5.24 | 5.32 | 5.3 | 5.29 | 14 |

| Festool | 6.57 | 6.54 | 6.61 | 6.57 | 15 |

| Skil | 6.53 | 6.56 | 6.68 | 6.59 | 16 |

| Bosch | 7.41 | 7.35 | 7.35 | 7.37 | 17 |

| Metabo 18V LTX | 8.01 | 9.02 | 8.65 | 8.56 | 18 |

| FEIN | 12.00 | 11.99 | 11.99 | 11.99 | 19 |

Driving Torque Comparison Testing | Winner Ryobi

We performed a driving torque test, it’s important to note, that these tools are impact drivers and NOT impact wrenches. We know from experience that many users will push their impact drivers to tighten or break fasteners larger than this tool was designed for. Because of this, we felt it would be valuable to provide you with relative data on applied torque.

We used a 1/2″ thick steel plate with a 9/16″ hole drilled into it. The impact drivers were all fitted with Milwaukee impact-rated sockets and 3/8″ adapters.

We applied torque to a 1/2″ grade-8 bolt, nut, and washer assembly, that was hand-tightened to a 1/2″ steel plate. Impacts were set to their highest speed or power setting available and torque was then applied for 6 seconds at which point the impact driver was removed. We performed this test five times per tool.

The nut assembly was then removed using a digital torque wrench meter. The meter allowed us to measure the peak torque required to break the nut.

The winner of this test was the Ryobi requiring an average breakaway torque of 1603 inch-pounds [in-lb] Second place went to DEWALT with 1400 in-lbs. followed by Bosch with 1322 in-lbs.

Note: At the beginning of this article we mentioned the huge range of voltages in this test ranging from 18V to 40V and our decision not to break up this group. As you can see from the these performance tests, the best average finishes were from the lower voltage impact drivers. The sweet spot for impact drivers (vs impact wrenches) is for installing small to medium diameter fasteners. These fasteners just don’t require the torque that would benefit from higher voltage platforms. So when it comes to choosing an impact driver voltage should not be your top consideration unless you’re trying to maximize a battery platform you own.

| Driving Torque Comparison Test | |||||

| MFG | Break 1 (in-lb) | Break 2 (in-lb) | Break 3 (in-lb) | Average (in-lb) | Rank |

| Ryobi | 1439 | 1777 | 1594 | 1,603.33 | 1 |

| DEWALT | 1361 | 1472 | 1366 | 1,399.67 | 2 |

| Bosch | 1430 | 1299 | 1237 | 1,322.00 | 3 |

| Skil | 1198 | 1398 | 1368 | 1,321.33 | 4 |

| Hart | 1215 | 1295 | 1322 | 1,277.33 | 5 |

| Kobalt | 1012 | 1327 | 1235 | 1,191.33 | 6 |

| Metabo 18 LT | 904 | 1220 | 1374 | 1,166.00 | 7 |

| Milwaukee | 1117 | 1177 | 1156 | 1,150.00 | 8 |

| Makita 40v | 1021 | 1046 | 1076 | 1,047.67 | 9 |

| Festool | 938 | 1138 | 1059 | 1,045.00 | 10 |

| FLEX | 1067 | 1036 | 1028 | 1,043.67 | 11 |

| Metabo 18LTX | 972 | 1231 | 827 | 1,010.00 | 12 |

| Hilti | 971 | 976 | 1033 | 993.33 | 13 |

| Makita 18v | 987 | 908 | 926 | 940.33 | 14 |

| FEIN | 639 | 852 | 880 | 790.33 | 15 |

| Ridgid | 595 | 588 | 550 | 577.67 | 16 |

| Metabo HPT 36v | 539 | 601 | 507 | 549.00 | 17 |

| Metabo HPT 18DC | 482 | 500 | 649 | 543.67 | 18 |

| Metabo HPT 18DBD | 411 | 371 | 384 | 388.67 | 19 |

NOTE on Bosch

All of the impacts, except the Bosch, require a 1/4″ to 1/2″ impact-ready drive adapter, to attach to the 3/4″ impact socket. The Bosch has a unique 2-in-1 feature allowing the user to directly attach 1/4″ hex bits and 1/2″ sockets directly to the tools drive head without the need for an adapter. Curious if there was an actual torque loss with using the impact adapter, we tested the Bosch with both. The 1/2″ direct-drive resulted in over 15% increase in torque measured, due to the reduction of toque loss through the required adapters. We used the higher value in our scoring matrix.

Self-Tapping Screw Test | Winner Makita 18 Volt

The self-tapping screw test involved fastening 5 total 3/4 in. screws into 16 gauge galvanized steel sheet metal while measuring the total fastening time. The 16 gauge steel served as a solid baseline for heavier-duty structural assembly or metal roofing applications. It was also a nice opportunity to test some of the application-based settings on some of the impact drivers. If the driver had a self-tapping mode then it was set for the test. Others featured a combo of low/medium/high settings. In those cases, we set the speed to the higher setting and backed off the variable speed trigger to avoid material stripping out at the end of the threading.

The Makita 18V driver set the bar with a total time of 22.3 seconds. It was set to self-tapping mode and did an excellent job ramping up on the initial drilling phase and then automatically slowing down when it sensed increased resistance from the screw head contacting the material.

This resulted in max speed fastening and no instances of stripping the sheet metal. The settings were easy to change on the base of the tool. We were also impressed with the soft, repeatable torque-sensing ability of this driver.

The Bosch came in second, only 2-tenths of a second slower than the Makita. It was also one of our favorites on this particular test. Bosch has an absolutely standout web application that allows the user to totally customize the tool settings. For this test, we designated one of the modes as the self-tapper mode and then customized it to a medium sensitivity with a stop setting when the torque limit was reached. Similar to the Makita, this resulted in max-speed tapping and fastening and zero material strip-outs. It also allows a user to increase the torque sensor sensitivity to high for thinner metals. It is a fantastic design, especially for sheet metal applications!

Lastly, the Ryobi came in third place with an overall time of 22.99 seconds. While it showcased impressive speed, it didn’t have the same feel or sensitivity as the Makita or Bosch impact drivers. The Ryobi struggled with material stripping out on at least one of the fasteners and was close on a second. It also didn’t have a dedicated self-tapper mode. It has a total of 4 speed/torque settings so we put it at speed 3. We likely could have decreased the risk of strip out by putting it to setting A (Assist) but the times were almost double on that setting.

The Hilti, Milwaukee, and DEWALT also stood out for their combinations of speed, touch, and overall performance on the self-tapping screw test.

| Sheet Metal Screw Test Results | ||

| MFG | Time (s) | Rank |

| Makita 18v | 22.30 | 1 |

| Bosch | 22.50 | 2 |

| Ryobi | 22.99 | 3 |

| Milwaukee | 23.06 | 4 |

| Metabo HPT DBD | 25.56 | 5 |

| FLEX | 25.58 | 6 |

| DEWALT | 25.68 | 7 |

| Makita 40v | 28.73 | 8 |

| Metabo 18 LTX | 29.04 | 9 |

| skil | 29.20 | 10 |

| Festool | 29.71 | 11 |

| Hart | 30.20 | 12 |

| Hilti | 30.89 | 13 |

| Metabo HPT DC | 31.60 | 14 |

| FEIN | 32.35 | 15 |

| Kobalt | 34.42 | 16 |

| Metabo 18 LT | 34.99 | 17 |

| Metabo HPT 36v | 39.01 | 18 |

| Ridgid | 41.59 | 19 |

Ergonomics | Winner Hilti

Next to performance and functionality, the way a tool feels in hand is an important purchasing consideration. Good ergonomic design helps reduce user fatigue, and in theory, should produce a better result. The old saying, “You never get a second chance to make a first impression,” applies here. For us, ergonomics is a lot like this saying. Users can often “feel” a tool that has great ergonomics long before they can articulate it. That was the Hilti for us.

For ergonomics, we looked closely at grip comfort, ease of bit change (collet function), LED lighting [line of sight], and ease of battery change.

The team gave input and feedback for each of these impacts and declared the top three tools based on the overall combined score of each section below:

Grip

The consensus of the group was that many of the impact drivers have comfortable grips. Depending on a user’s hand size opinions will vary and we recognize that this is our subjective opinion. All of the impacts had some form of rubber over-mold on the handles, but the Makita 18-volt and 40-volt stood out. The team felt that both Makitas impacts had really comfortable grips.

Kobalt, Fein, DEWALT, and Bosch had a well-thought-out placement of rubber and felt very balanced in our hands. Due to the closeness in grips, and varying opinions of the team, we chose not to give these impacts a score in this evaluation.

Bit Change

Is bit change important to you? Maybe, maybe not… If you have the mindset like our crew, efficiency is time, and time is money. 11 of the 19 impacts have one-handed bit insertion which earned them a seat at the top.

One-handed bit insertion means that all you have to do is press the bit into the spring-loaded collet and it automatically locks in and holds the bit secure.

3 out of the 11 really stood out. The DEWALT, Festool, and Milwaukee rose to the top with the smoothest and least resistance collet [inserting and removing].

The team did not like the fact that Ridgid, Ryobi, and Hart eject the bit when the collet was released. We recognize that this is a subjective opinion, but our thought is an ejected bit will most likely fall on the floor, or off staging and in the dirt when swapping bits.

The other 8 remaining impacts all have a 2 handed operation. One hand to hold the collet back while the other hand is needed to insert the bit.

LED Lights

The impacts with the best LED arrays were the Skil and the Hilti. Both of these impacts have diffuser ring lights offering full 360° lighting around the head of the impact. That being said, the Hilti light was the brightest of the two.

The second place tier in LED light scoring was the DEWALT, Metabo HPT 18DC, Metabo HPT 36v, and Milwaukee. All of these impacts have three LED lights around the head.

3rd tier impacts were the Makita 18v and the Makita 40v impacts with 2 lights located at the 3 and 9 o’clock positions. Metabo HPT DBD 18v took 4th tier with one single light on the bottom of the head at the 6 o’clock position.

Bosch, Fein, Festool, Flex, Hart, Kobalt, Metabo LT, Metabo LTX, Ridgid, and Ryobi placed 5th due to them having the LED in the base of the tool, resulting in the light shining up. The team did not like this location due to issues where lights can be blocked by hands when wearing gloves, or create shadows.

Editor’s Note

The Metabo HPT impacts have push-button flashlight modes, which allow the LED light to stay on. No more having to press the trigger to turn on the LED light.

Battery Change | Battery Release Button

The ease of battery removal was evaluated. The team favored a one-button removal and ranked the tools accordingly. The winner of this category was the Hilti impact driver. Hilti has a spring-loaded assist, almost like an auto-eject button. When the button is pressed the battery springs forward assisting with removal.

The other single-button battery removal impacts Push button battery removal impacts are the Bosch, DEWALT, Fein, Flex, Hart, Makita, and Skil.

The Kobalt, Milwaukee, and Ridgid have two “pinch style” buttons on each side of the battery to release it from the tool. Unlike the other tools with two buttons, these three are nicer, with larger buttons that are easier to manipulate.

The Metabo impacts have a battery release button on the back of the tool, the team found that this was not intuitive and difficult to use. It is awkward to operate as you have to push the button while pulling the battery in opposite direction. This is something we have been asking Metabo to update for years.

Best Cordless Impact Ergonomics | Winner Hilti

The Hilti stood alone in Ergonomics with a combined score of 4. It scored top marks in LED lighting and battery change and landed in the second tier for fastener changing.

A tie for second place was the DEWALT and Skil with 5 points in all three categories. Third place was Milwaukee with 6 points total ( 1 for bit change, 2 for LED light, and 3 for the battery change).

The two impacts that received 5’s in all three categories are the Metabo LT and LTX. The crew believes that the Metabo needs to improve its battery release mechanism.

| Ergonomics Qualitative Scoring Results | |||||

| MFG | Bit Change | LED Lights | Battery Change | Total | Rank |

| Hilti | 2 | 1 | 1 | 4 | 1 |

| DEWALT | 1 | 2 | 2 | 5 | 2 |

| Skil | 2 | 1 | 2 | 5 | 2 |

| Milwaukee | 1 | 2 | 3 | 6 | 4 |

| Makita 18v | 2 | 3 | 2 | 7 | 5 |

| Makita 40v | 2 | 3 | 2 | 7 | 5 |

| Festool | 1 | 5 | 4 | 10 | 7 |

| Hart | 3 | 5 | 2 | 10 | 7 |

| Kobalt | 2 | 5 | 3 | 10 | 7 |

| Bosch | 4 | 5 | 2 | 11 | 10 |

| Metabo HPT 18DC | 5 | 2 | 4 | 11 | 10 |

| Metabo HPT 36v | 5 | 2 | 4 | 11 | 10 |

| Ridgid | 3 | 5 | 3 | 11 | 10 |

| FEIN | 5 | 5 | 2 | 12 | 14 |

| FLEX | 5 | 5 | 2 | 12 | 14 |

| Ryobi | 3 | 5 | 4 | 12 | 14 |

| Metabo HPT 18DBD | 5 | 4 | 4 | 13 | 17 |

| Metabo 18 LT | 5 | 5 | 5 | 15 | 18 |

| Metabo 18V LTX | 5 | 5 | 5 | 15 | 18 |

Best Features | Winner Bosch

All of these impact drivers have standard features common with impact drivers these days, consisting of multiple drive modes, LED lights, spring-loaded collets, belt hooks, and battery gauges. Approximately 60% of them have specialty drive modes.

Driver Settings | Makita

Both Makita’s have multiple specialty drive modes allowing you to dial in speed, tightening modes, assist modes, and auto stop modes for different fasteners and materials. While we were impressed with this the consensus was that unless you are a specialty contractor these modes will mostly go unused.

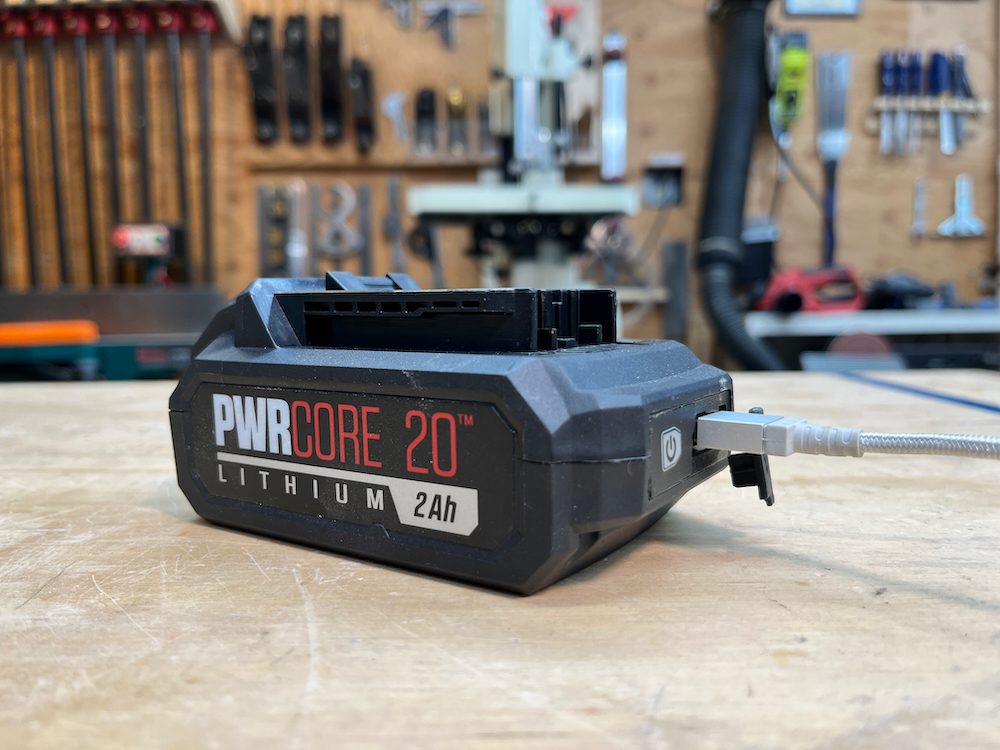

USB Battery Charging | SKIL

The Skil battery has a built-in USB port for easy charging. Most brands have an adapter that will slide over the battery to enable charging but the Skil has it right on the battery. This is an innovative idea that the team really appreciated.

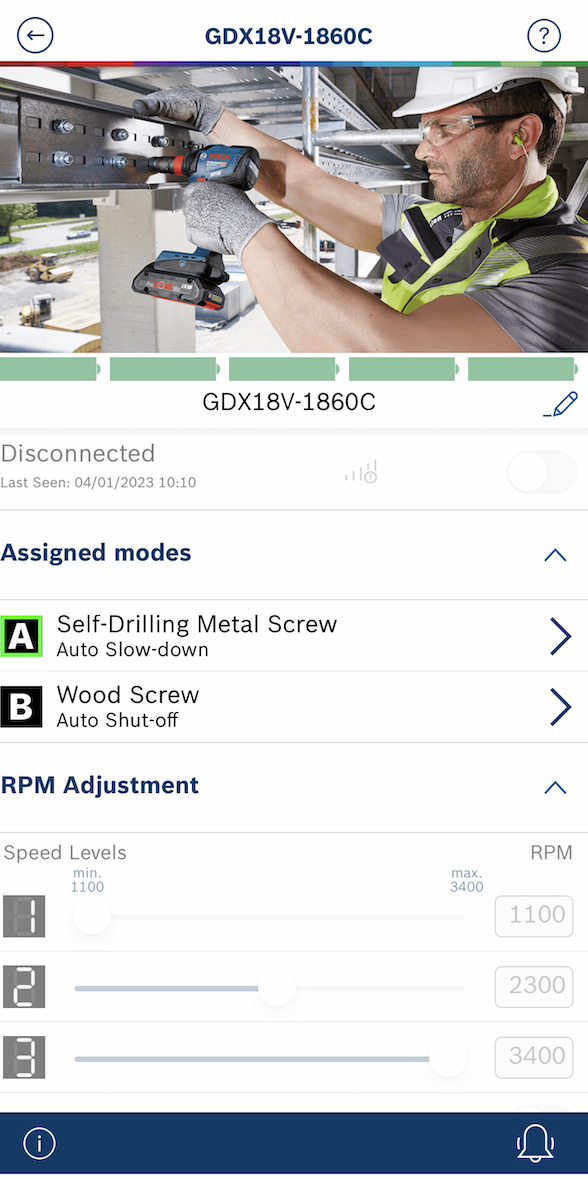

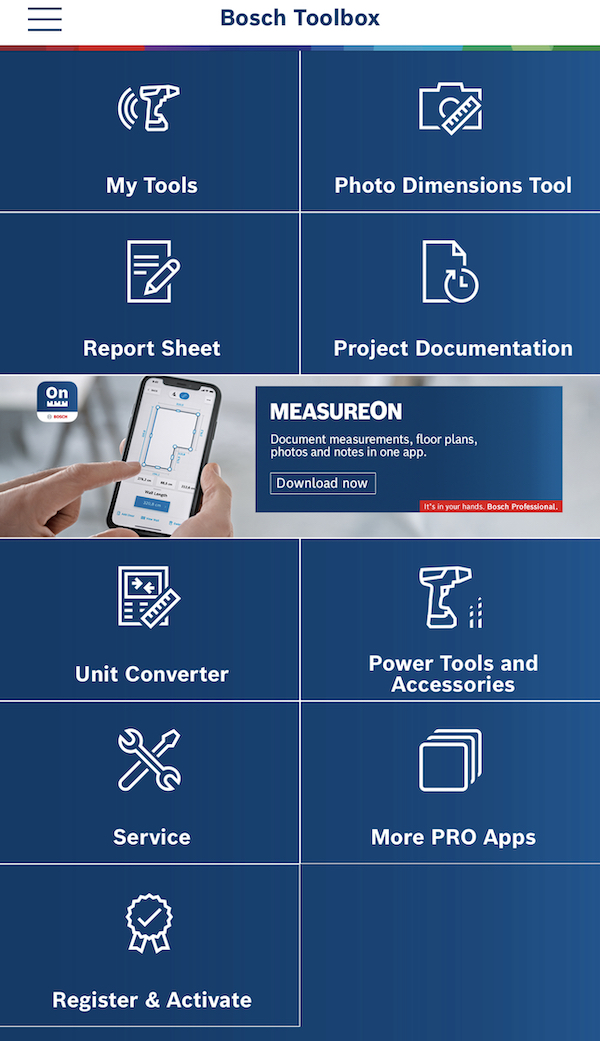

Bluetooth AP | Bosch

Bluetooth functionality is becoming more and more common as manufacturers add these features to their tool brands. In this Impact Head to Head, Bosch’s entry was the only tool to have such a feature. The “Bosch ToolBox” is a smartphone app that connects to a Bluetooth module roughly the size of a quarter installed into the grip of the driver. Once paired, the user can customize two Assigned slots with pre-filled smart modes for self-tapping screws, specialty wood screws, and bolts. The 3-speed levels of the other tool side selectable buttons can be changed.

The Bosch Toolbox app also has some great features like its Photo Dimensions Tool that uses your phones camera to grab rough measurements and draft layouts. The Bosch Toolbox app coupled with the unique, 2 in1 Driver/Wrench feature, elevated the tool as true standout in the Feature category.

| Features Qualitative Scoring Results | ||

| MFG | Score | Rank |

| Bosch | 1 | 1 |

| Makita 18v | 2 | 2 |

| Makita 40v | 2 | 2 |

| Skil | 2 | 2 |

| Festool | 3 | 5 |

| FLEX | 3 | 5 |

| Kobalt | 3 | 5 |

| Metabo HPT 18DC | 3 | 5 |

| Metabo HPT 18DBD | 3 | 5 |

| Metabo HPT 36v | 3 | 5 |

| Milwaukee | 3 | 5 |

| Ridgid | 3 | 5 |

| Ryobi | 3 | 5 |

| DEWALT | 4 | 14 |

| Hilti | 4 | 14 |

| Metabo 18 LT | 4 | 14 |

| Metabo 18LTX | 4 | 14 |

| FEIN | 5 | 18 |

| Hart | 5 | 18 |

Best Size and Weight | Winner DEWALT

Size matters to users, in this case, they want a smaller, compact impact driver that still has the power for the applications they need to deploy it in. Compact also means that the tool can be used in more situations, think of tight spot applications like sistering floor joists with a 5 or 6-inch fastener, in between joist bays. We felt the two most important factors for an impact driver were the weight and head length. Having a lightweight tool when working overhead, coupled with a compact size that can fit into small openings is a huge win.

To determine a final ranking for size and weight, each driver was weighed without the battery and the head length, from bit holder/collet to back was measured. Each of these values were ranked separately and then combined into a single factor to determine the winner. The DEWALT was the most compact impact driver of the bunch. It measures 3.9″ and weighs 2.1 lbs and is 1/2″ smaller than the 2nd place Metabo HPT 18DC which measures 4.51 inches and measures 2.0 lbs. Third place was the Makita 18V measures 4.53 inches and weighs 1.9 lbs.

An interesting fact is that all of the tools weigh from 1.9 lbs. to 3.3 lbs.

| MFG | Length (in) | Weight (lb) | Rank |

| DEWALT | 3.94 | 2.10 | 1 |

| Metabo HPT DC | 4.51 | 2.00 | 2 |

| Makita 18v | 4.53 | 1.90 | 3 |

| Milwaukee | 4.48 | 2.20 | 4 |

| Makita 40v | 4.77 | 2.20 | 5 |

| Metabo 18V LTX | 5.10 | 2.10 | 6 |

| Ridgid | 5.02 | 2.20 | 7 |

| Festool | 5.17 | 2.12 | 8 |

| Metabo HPT 36v | 4.52 | 2.50 | 8 |

| Hilti | 5.44 | 2.20 | 10 |

| Skil | 4.92 | 2.47 | 10 |

| FLEX | 4.68 | 2.70 | 12 |

| Kobalt | 5.27 | 2.40 | 12 |

| FEIN | 6.00 | 2.20 | 14 |

| Metabo HPT DBD | 5.04 | 2.90 | 15 |

| Hart | 5.82 | 2.50 | 16 |

| Ryobi | 5.60 | 2.55 | 16 |

| Metabo 18 LT | 5.64 | 2.60 | 18 |

| Bosch | 5.82 | 2.60 | 19 |

Best Cordless Impact Price | Winner Skil

Price is undoubtedly an important consideration when buying tools, especially for those of you who are just starting out in the trades. We can certainly agree on that and also agree that the majority of contractors have strong brand loyalty and would rather continue with their current battery platform than venture out and create a new line of cordless power tools.

We did not include the price in our scoring criteria but included bare tool pricing for you to use as needed.

The best-priced impact driver was the Skil coming in at $69.99 bare tool. The second lowest price was the Hart at $77.85 and the third was the Bosch at $99.00. The team all agrees that the Skil and Hart impact drivers fall into the DIY category for users.

| Pricing Ranking | ||

| MFG | Score | Rank |

| Skil | $69.99 | 1 |

| Hart | $77.85 | 2 |

| Bosch | $99.00 | 3 |

| Ryobi | $119.00 | 4 |

| Metabo HPT 18v | $129.00 | 5 |

| Metabo HPT | $129.00 | 5 |

| Metabo 18 LT | $131.99 | 7 |

| Ridgid | $139.00 | 8 |

| DEWALT | $149.00 | 9 |

| Kobalt | $149.00 | 9 |

| Milwaukee | $149.00 | 9 |

| FLEX | $159.00 | 12 |

| Metabo 18V LTX | $179.99 | 13 |

| Metabo HPT 36v | $189.00 | 14 |

| Hilti | $199.00 | 15 |

| Makita 40v | $217.00 | 16 |

| Festool | $219.00 | 17 |

| Makita 18v | $219.00 | 17 |

| FEIN | $308.00 | 19 |

The most expensive impact driver we tested was the Fein, coming in at $308.00. The Makita 40v at $217 and the Festool at $219.00 [bare tools] The majority of these impact drivers are available online at ACME Tools.

The Kobalt impact driver was the only tool that is not sold as a bare tool. The Kobalt comes in at $149.00. This kit includes the impact, one 4.0Ah battery, a charger, and a carrying bag.

Best Cordless Impact Driver | Winner Milwaukee

At the end of the day, our goal is to determine which cordless impact driver is the best overall. This decision is not based on conjecture but on real-world quantified data and testing. After completing all of our tests and analyzing the results. The impact driver that hovered at the top in all our tests was Milwaukee.

The Milwaukee scored 2nd in two performance tests [Structural and Deck Screws], 3rd in size and weight [compactness], and 4th in both Ergonomics and the Self-Tapping screw test. It is a powerful, compact, well-designed, and robustly built impact driver.

| MFG | Deck Screw | Structural Rig | Torque | Sheet Metal | Ergo | Feat | Size | Total Score | Rank |

| Milwaukee | 2 | 2 | 8 | 4 | 4 | 5 | 4 | 29 | 1 |

| DEWALT | 6 | 8 | 2 | 7 | 2 | 14 | 1 | 40 | 2 |

| Makita 40v | 5 | 10 | 9 | 8 | 5 | 2 | 5 | 44 | 3 |

| Makita 18v | 7 | 13 | 14 | 1 | 5 | 2 | 3 | 45 | 4 |

| FLEX | 2 | 1 | 11 | 6 | 14 | 5 | 12 | 51 | 5 |

| Skil | 9 | 16 | 4 | 10 | 2 | 2 | 10 | 53 | 6 |

| Metabo HPT 18DC | 2 | 7 | 18 | 14 | 10 | 5 | 2 | 58 | 7 |

| Ryobi | 9 | 14 | 1 | 3 | 14 | 5 | 16 | 62 | 8 |

| Metabo HPT 36v | 1 | 4 | 17 | 18 | 10 | 5 | 8 | 63 | 9 |

| Bosch | 15 | 17 | 3 | 2 | 10 | 1 | 19 | 67 | 10 |

| Kobalt | 12 | 9 | 6 | 16 | 7 | 5 | 12 | 67 | 10 |

| Ridgid | 7 | 3 | 16 | 19 | 10 | 5 | 7 | 67 | 10 |

| Festool | 18 | 15 | 10 | 11 | 7 | 5 | 8 | 74 | 13 |

| Hilti | 14 | 12 | 13 | 13 | 1 | 14 | 10 | 77 | 14 |

| Metabo HPT 18DBD | 11 | 5 | 19 | 5 | 17 | 5 | 15 | 77 | 14 |

| Hart | 13 | 11 | 5 | 12 | 7 | 18 | 16 | 82 | 16 |

| Metabo 18V LTX | 16 | 18 | 12 | 9 | 18 | 14 | 6 | 93 | 17 |

| Metabo 18 LT | 17 | 6 | 7 | 17 | 18 | 14 | 18 | 97 | 18 |

| FEIN | 19 | 19 | 15 | 15 | 14 | 18 | 14 | 114 | 19 |

It’s interesting to note that Milwaukee is a Generation 4 driver. That means that since 2012 they have updated it 4 times. Milwaukee has proven that they are dedicated to solving user challenges and improving its tools regularly. Clearly, this trade-focused approach is based on service history, and end-user research to update their tools. The team was impressed with its performance.

Second place went to the DEWALT, it scored 1st place in size/weight and 2nd place in both our torque test and ergonomics.

Third place went to the Makita 40V which finished 2nd in features, and top 5 in Deck Screw Performance, Size and Weight and Ergonomics Categories. Its Makita 18V sibling finished just 1 point away in our final scoring.

Best Value Impact Driver | Skil

This category winner often resonates with people because it highlights a tool that performed well in our tests while still being cost-effective. As we mentioned earlier we did not score the price. However, we’d be remiss if we didn’t talk about a best-value tool – who doesn’t like a deal – right?

When considering the ranking in our 7 scorable criteria categories and then looking at bare tool price it’s hard not to look at the Skil impact driver. The Skil sells for the lowest price, it scored 2nd in both Economics and Features and 3rd in the Applied Torque testing for an overall score of 6th place out of 19 impact drivers.

The SKIL impact driver also tied for 4th place with the Makita 40 volt for Best Overall Impact Driver.

Final Thoughts – Full-Size Impact Drivers

This was such a fun evaluation because the field was so closely matched. These tools competed for razor-thin margins. For many users, the decision on which impact driver they should buy will likely be based on the battery platform they own.

The bottom line is this, almost all of these impact drivers are very capable of performing most any fastening task for small and medium size fasteners. If one of the categories is not important to you as a user, check out the data and make a determination yourself. The often-asked question but one we don’t address is long-term durability.

Durability and Longevity

Impact drivers experience significant wear and tear over time. As a result, you should invest in a cordless impact driver that is long-lasting and dependable. Many pro-users are not interested in faster driving capabilities but want a tool that can maintain a consistent driving speed and last longer.

The entire Tool Box Buzz team owns and uses 5 of these impact drivers daily for this reason. The best way to answer long-term reliability is to invest in a pro-grade tool brand. In contrast, we’ve experienced many of the non-pro or newer tool brands burn out in 6-months after deploying in the field.

There are several pro-grade impact drivers in this test, I’ll use the Festool as an example. In their research and testing Festool found that the most frequent failure point on impact drivers was the anvil mechanism, so they adjusted the shape and material hardness of their anvil to increase the lifespan of the tool. They also decreased the internal strike speed (BPM) so it was less likely to break.

Festool also incorporated a longer trigger which allows for finer control of the variable speed trigger making it easier to manually control slow speed on hardware attachment. The moral of the story here is that pro-grade tools are designed to last longer, for us PROs a tool is an investment that is needed for our livelihood – invest wisely!

Buy Now From Our Sponsored Retailers

Other Options

ACME TOOL | Head-To-Head Sponsor

Acme Tools celebrates 70 years of experience serving customers and continues to be one of the premier retailers of tools and equipment and the best online tool store in e-commerce. They serve the contractor, woodworker, and do-it-yourselfer with a wide selection of tools and equipment from all the major manufacturers. Whether you shop in-store, on your smartphone, or from their catalog, ACME Tools will save you time and money by serving as a source for products to make your job or project purchasing easier

Check Out Our Other Head-To-Head Tests

The crew at Tool Box Buzz produces many Head-to-Head articles. We welcome you to swing over to our Head-To-Head page and check out all of them! You will not be disappointed

Best Impact Driver Video Review

About the author

4 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Very well done! It has been a few years since I have done tool tests for a magazine, but something I has always wanted to do was a cordless tool longevity comparison. Subjectively I have my choices, but I would love to see an objective analysis of the pro tools and what kind of life cycle each has. I have noticed some tool manufacturers have fewer battery issues, but I would like to see a more up to date evaluation.

Change has to have, I was typing on my phone and autoincoorect changed this without my noticing.

Great review! I have a couple comments regarding the Bosch model.

First, I wish that reviewers would include Bosch’s “regular” impact driver (GDR18V-1860CN) instead of (or in addition to) the “Freak” model (GDX18V-1860CN). This omission is really Bosch’s fault, because they have really pushed the “freak” model despite it being much larger and possibly weaker as an impact driver compared to the regular model.

Second, your findings regarding the Bosch’s torque are exactly the opposite of what was found by Torque Test Channel on Youtube. They found that the “freak” made substantially more torque *with* an adapter. This was an unexpected finding and they discussed it at some length.

To my knowledge, not a single reviewer has measured the performance of the “regular” Bosch impact, nor compared the performance of the “freak” with the “regular” impact. Although they have the same ratings on paper, the very different designs are likely to result in very different real-world performance.

Any chance you would add the regular Bosch impact to your tests?

Ken – We reach out to all the major brands and ask them to participate in these tests and submit samples that fit into the “category” that we are testing. We rely on them to submit what they feel is the best fit for the group we are testing. Obviously we send them some suggestions, but the samples they send are ultimately their choice. We could never “fund” purchasing all these tools ourselves so we rely on samples from all of them. So to answer your question…no we won’t be adding that to the mix. I really understand your request and wish we could add it, but it’s just not feasible.