Cleaning and Lubricating Woodworking Machines

Keeping Woodworking Machines Clean

Keeping Woodworking Machines Clean

Cleaning and lubricating woodworking machines is a maintenance issue that is often overlooked in the workshop. We all just want our tools to work, when we work with them! The problem is if you don’t keep your woodworking machine moving parts clean and lubricated, they can rust or become coated with grit and debris and even become expensive problems and or breakdown.

The good news is that most maintenance can be done in a minimal amount of time and effort, and once done becomes easier on subsequent cleanings.

Tips on Cleaning and Lubricating Woodworking Machines

Woodworking machines live and operate in a dusty environment. While efficient dust collection is a MUST in any shop, it still will not pick up all the dust in a shop, nor will it keep the undersides of your machines clean.

For example, on a table saw, the need for cleaning and lubrication become obvious when it becomes difficult to operate the blade elevation and blade-tilt wheels.

Cleaning Woodworking Machines Moving Parts

Here’s some tips on how to remove old grease and sawdust from your machines and get them to operate smoothly again:

- Unplug the saw.

- Remove the throat plate, blade guard, and the blade.

- Inspect the blade for resin buildup, and clean it if necessary.

- Make sure that the washer and blade stabilizer (if used) are clean, smooth, and flat.

- Use compressed air and your dust collection system to remove loose sawdust.

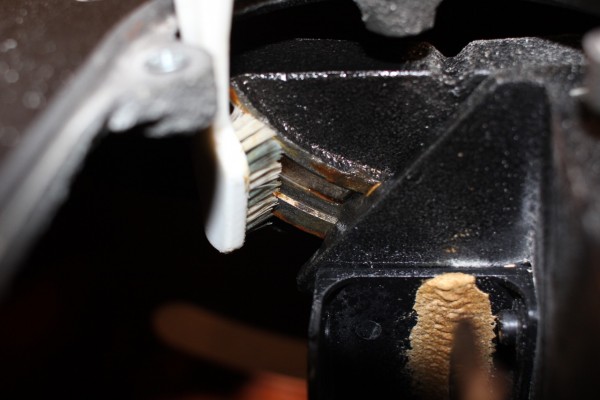

- A vacuum with a crevice attachment is extremely effective at sawdust removal, and an old paintbrush will help loosen stubborn pockets of dust on gears and other parts.

- Tilt the arbor assembly to dump more dust, and use a couple of blasts of compressed air to complete the job

- If the worm gears have any old grease residue, scrub them with a paint brush or a brass brush before new lubricants can be added. Removing old grease often requires the use of solvents, you may have to dip the brush in paint thinner. Keep the solvent away from the arbor bearings, which are usually sealed and need no lubrication.

Lubricants are Sawdust Magnets – Use 3-in-One Dry Lube

One of the greatest challenges with using lubricants in a wood-shop is that they are often sticky and tend to attract dust. I prefer using dry lube because it quickly sets up and dries, leaves a thin lubrication coating that does not attract sawdust like oil, grease or lithium grease. Using 3-in-One Dry Lubricants only leaves a thin film that is less of a dust magnet.

- After all of the gearing is clean, lubricate the gears, pivots of the arbor assembly (where it swings upward) and the shafts behind the worm gears with 3-in-One Dry Lube.

- Run the tilt and elevation controls through several full ranges of motion to distribute and spread out the lubricant.

- Lubricate all moving parts at hinge or pivot points.

- See link below on what to apply to woodworking machine top surfaces.

Clean Regularly, Lube Often!

Keeping these woodworking machine moving parts lubricated is key, so get into the habit of doing regular cleaning and maintenance to your tools. I clean and lube mine quarterly, or when I notice sluggish performance in operation.

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.