CHANNELLOCK – American Made and Proud Of It

CHANNELLOCK – Founded in 1886 and Still Making US Made Pliers 126 Years Later

Occasionally I get the good fortune of experiencing something that makes me feel really great. Things like walking through an airport and thanking a member of the military, volunteering for a great cause, or reading about a successful start up company. Well this week I was fortunate enough to get that sense when I visited the headquarters of CHANNELLOCK.

So what’s the big deal? The big deal is that CHANNELLOCK is a 5th generation family run business that’s in it’s 126th year since 1886! When you consider the fact that we live in a world of increasing outsourcing and a vast majority of tools being built in places like China the CHANNELLOCK story is one that really impresses me.

US Made and Sourced Pliers

CHANNELLOCK sells several different kinds of tools but they are best known for their pliers. They literately sell dozens of types of pliers for everything from working on small delicate carburetors to huge pliers for electricians working on huge conduit. All of their pliers are made from 100% North American Steel and built here in the US. Over 400 proud Americans work for CHANNELLOCK pumping out thousands of pliers per day! If this story doesn’t make you proud I’m not sure what kind of story would.

Forged From Raw Steel

Each and every set of pliers that CHANNELLOCK makes starts out from a piece of round bar stock C1080 steel from Nucor and Eaton steel companies. The pieces of raw steel are placed into a die f0rge press and pounded into the shape of the tool. As you can see above the piece of steel comes out of the die so hot that it’s bright red. After each of the pieces if forged into the rough shape it is softened with height to allow easier machining.

Once the pieces leave the forging area workers machine channels, holes, slots and other features into the pliers. The work is done with a combination of old and new machining techniques.

As you can see above one of the pliers after forging and before machining. The piece below it has just finished having the channels machined.

Workers also grind, polish and check each piece for a precise fit. Some of the tedious grinding processes like the one shown above are now being done with robots. Asked whether or not robots have replaced workers the management at CHANNELLOCK surprisingly told us they have not. Workers have been tasked to other jobs and in some cases robots have filled the shoes of workers that have retired.

Quality Makes The Difference

I was also very impressed with the investments that CHANNELLOCK has made to improve overall quality. The company has recently invested in laser hardening equipment that allows them to more precisely harden cutting edges and teeth on pliers.

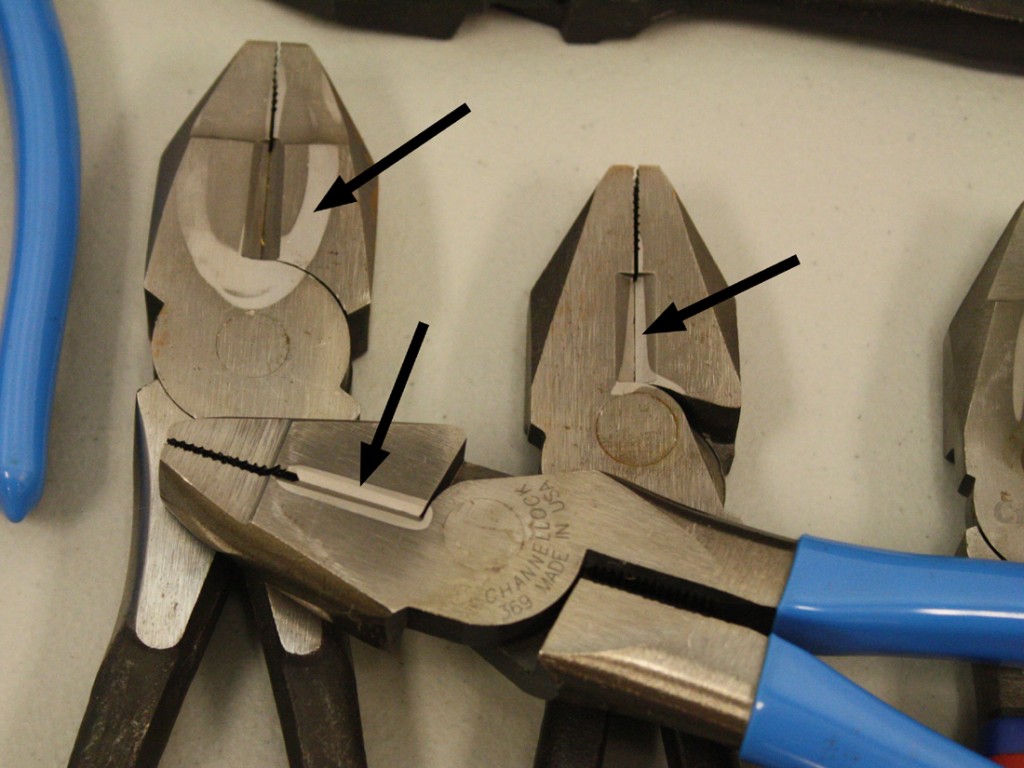

If you look at the three sets of linesman pliers above you’ll see a “light” shiny area indicated by the arrow at each of the cutting areas. That area indicates the area on the pliers that has been heat treated to increase the strength and durability of the cutting edge. The areas were highlighted by sanding them and applying an acid which means the areas shown are the actual areas affected by heat strengthening.

If you look closely you’ll see the CHANNELLOCK plier has a very uniform, consistent area of heat strengthening. The other pliers are not nearly as accurate and one didn’t even have the cutting edge hardened. That’s because the CHANNELLOCK plier was hardened using a laser and the others were done using an older method that’s very hard to apply accurately.

After the pliers are finished they go through one last heat strengthening process. This helps reverse the earlier step that made the pliers easier to machine. The crate shown above is holding hundreds if not thousands of pliers that are coming out of the furnace. Each day they crank out thousands and thousands of pliers.

Grips and Shipping

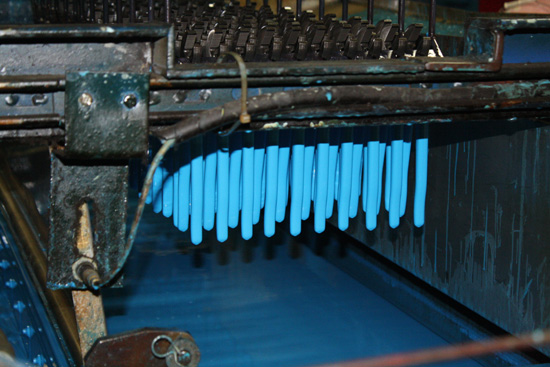

Once all of the forging, machining, and hardening is complete each of the pliers is given a grip. Grips range from the classic plastic dip handle to the newer Code Blue plastic grips.

The handles are dipped into a liquid bath of PVC rubber so that each handle is evenly coated. The finished pliers are then sent down the factory line for shipping.

Final Thoughts

I was so impressed with everyone at CHANNELLOCK from the owners down to the employees. It’s such an incredible story that I feel it needs to be celebrated. I know they have some of the worlds best pliers, when you combine that with the fact that they are US made it’s a no brainer to keep your crews outfitted with the best tools. If you want top quality pliers built here in the US then I highly recommend CHANNELLOCK pliers. You won’t regret the decision as they will likely last your lifetime and your kids as well.

About the author

5 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Love all the additional pictures. Any of their other products made in the USA or just pliers?

Everything except their levels

Screwdrivers and adjustable wrenches are over seas as well.

There’s a lot of blue handles in my tool box for a few good reasons. Durable, high quality tools, made in the USA and the prices are even reasonable! What’s not to like?

Right on Ethan! My tool box is like yours, a lot of blue.